Abstract

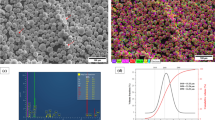

The NM500/Q345/NM500 composite plates were subjected to different hot rolling and heat treatment processes in this paper. The influence of hot rolling and heat treatment on the microstructure, element distribution and defect composition of the bonding interface of the as-rolled clad plates was studied by using optical microscope, scanning electron microscope, electron backscattered diffraction and transmission electron microscope. Meanwhile, the mechanical properties of wear-resistant steel were analyzed by microhardness and tensile tests. It was revealed that the increase in rolling reduction promoted the metallurgical bonding between NM500 and Q345 steels. The composite texture components of {112} ~ {113} < 110 > , {332} < 113 > , {223} < 110 > , {554} < 225 > and < 110 > ∥RD were formed in the tissue when the reduction rate was 70%. γ/α phase transformation reinforced the texture components and thus increased {332} < 113 > and {554} < 225 > after quenching treatment. Typical lath martensites were present in the structure, and there were high-density dislocations and substructures between the laths. Tempering treatment at 200 °C facilitated the deposition of some needle-like or rod-like ε precipitates in the martensite. The best tensile strength (1432.28 MPa) and elongation (22.68%) in the composite plate could be achieved by post-rolling treatment of quenching at 900 °C and tempering at 200 °C.

Similar content being viewed by others

References

Raabe D, Sandlbes S, Millán J et al (2013) Segregation engineering enables nano scale martensite to austenite phase transformation at grain boundaries: A path way to ductile martensite. Acta Mater 61:6132–6152

Deng Jie, Song Xinli, Zheng Aiqin, et al (2019) Effect of tempering temperature on microstructure and mechanical properties of Cu-Cr-Ti martensite wear-resistant steel. J Iron Steel Res int. 31:1031–1038. https://doi.org/10.13228/j.boyuan.issn1001-0963.20190097

Zhang JQ, Du JM, Guo JW (2012) Influence of Mn and Heat Treatment Technology on Microstructure and Mechanical Properties of a Low-Alloy Wear-Resistant Cast Steel Shovel Tooth. Adv. Mater. Res. 557:34–37

Renbo S, Yifan F, Shiguang P (2015) Research and Application of High Manganese Steel Lining Plate. Mater Rev. 29:74

S.G. Peng, R.-B. Song, W, Wang (2016) Effect of Heat Treatments on Microstructure and Mechanical Properties of Novel Light-mass Austenitic Wear-resistant Steel. J Mater Eng. 44: 24–31. https://doi.org/10.11868/j.issn.1001-4381.2016.09.004

Liang L, XiangTao D, Kaiming Wu (2018) Erosion wear behavior of low alloy abrasion resistance steel plates. Steel Rolling 035:10–16

Tang Lin lin (2011) The Performance Characteristics and Application of High Chromium Wear-Resistant Composite Panels. Opencast Mining Techn 2:82–83

Qiu XW, Zhang YP, Chun GL (2012) Study on Ware Resistance of Laser Hardening Rolling Mill Liner. Applied Mechanics and Materials 121:3551–3554

Xiong B, Cai C, Lu B (2011) Effect of volume ratio of liquid to solid on the interfacial microstructure and mechanical properties of high chromium cast iron and medium carbon steel bimetal. J Alloy Compd. https://doi.org/10.1016/j.jallcom.2011.03.142

Liu F, Jiang Y, Lu D (2014) Microstructure evolution and impact toughness of sandwich structured composite preparedby centrifugal casting and hot rolling process. Mater Sci Tech-lond 31:295–302. https://doi.org/10.1179/1743284714Y.0000000514

Ramadan M (2015) Interface Characterization of Bimetallic Casting with a 304 Stainless Steel Surface Layer and a Gray Cast Iron Base. Adv. Mater. Res. 1120:993–998. https://doi.org/10.4028/www.scientific.net/AMR.1120-1121.993

Li Y, Gong M, Wang K (2018) Diffusion behavior and mechanical properties of high chromium cast iron/low carbon steel bimetal. Mater. Ence. Eng. A 718:260–266. https://doi.org/10.1016/j.msea.2018.01.111

Li L, Chen M (2016) Production Technologies and Industrial Application of Wear Resistant Clad Steel Plate. Wide & Heavy Plate 22:38–43

Zhao G, Huang Q, Zhou C (2016) Experiment and simulation analysis of roll-bonded Q235 steel plate. Rev. Metal. Madrid. 52:e069. https://doi.org/10.3989/revmetalm.069

Li J, Zhao G, Huang Q (2017) Experimental and Simulation Analysis of the Successful Production of Heavy-Gauge Steel Plate by the Clad Rolling Process. Int. J. Nonlin. Sci. Num. 18:403–409

Qiu J, Cheng X, Lan K (2017) Effect of Rolling and Heat-Treatment on Structure and Properties of Wear-Resistant Steel NM450D-Carbon Steel Q235B Clad Plate. Special Steel 2:56–59. https://doi.org/10.3969/j.issn.1003-8620.2017.02.015

Lan K, Cheng X, Qiu J, et al (2017) Influence of Reduction Ratio on Interfacial Bonding Properties of Wear-resistant Steel and Carbon Steel Composite Board. Hot Working Technology. 20: 121–124 https://doi.org/10.14158/j.cnki.1001-3814.2017.20.032

Chuangwei G (2015) Research on Rolling Process of Wear-resistant and Carbon Steel. Wuhan University of Science and Technology. https://doi.org/10.7666/d.D641107

Li HY, Zhao G, Ma L (2018) Microstructure analysis of hot-rolled NM500/Q345/NM500 composite interface. Mater Res Express 6:016548. https://doi.org/10.1088/2053-1591/aae751

Liu P, Ma L, Jia W (2019) Hot deformation behavior of a novel bimetal consisting of BTW1 and Q345R characterized by processing maps. Front Mech Eng 14:489–495. https://doi.org/10.1007/s11465-019-0554-x

Xia-Xu H, Yan-Hua S, Shun-Yao J (2019) High-temperature wear performance and mechanism of NM400/NM500 mining machinery steels. Chinese journal of engineering.https://doi.org/10.13374/j.issn2095-9389.2019.06.012

Deng X, Wang Z, Misra RDK (2019) Transformation and precipitation behaviour of Ti-Mo bearing high strength medium-carbon steel. Mater Sci Tech-Lond 29:1111–1117. https://doi.org/10.1179/1743284713Y.0000000290

Lv Q, LiTang, (2001) Guangnan Chen Textures in hot rolled steel sheet. Iron Steel Vanadium Titanium Iron Steel Van Tit. 22:2–4

Xu Hui,Li Tiansheng (2020) Effect of tempering temperature on microstructure and mechanical properties of Nb microalloyed NM500 steel. Heat Treat Met. 9:116–120. https://doi.org/10.13251/j.issn.0254-6051.2020.09.021

Zhu C, Cerezo A, Smith GDW (2009) Carbide characterization in low-temperature tempered steels. Ultramicroscopy 109:545–552. https://doi.org/10.1016/j.ultramic.2008.12.007

Ceschini L, Marconi A, Martini C (2013) Tensile and impact behaviour of a microalloyed medium carbon steel: Effect of the cooling condition and corresponding microstructure. Mater. Design 45:171–178. https://doi.org/10.1016/j.matdes.2012.08.063

Pan X, Umemoto M (2018) Precipitation Characteristics and Mechanism of Vanadium Carbides in a V-Microalloyed Medium-Carbon Steel. Acta Metall Sin (Engl Lett). 31:1197–1206. https://doi.org/10.1007/s40195-018-0775-8

Jia T, Li M, Pei X (2018) On the Spheroidizing Annealing Behavior in Cr/Nb Microalloyed Medium Carbon Steels. Steel Res Int 1800353:1–11. https://doi.org/10.1002/srin.201800353

Acknowledgements

This project was supported by the National Key Research and Development Program of China(2018YFA0707305), the Shanxi Province Science Foundation for Youths(201801D221120), Taiyuan University of Science and Technology Postdoctoral Research Startup Fund (20192024), the Key Research and Development Program of Shanxi Province(201703D111003), the Science and Technology Major Project of Shanxi Province(20181101015), the Start-up Foundation for Doctor of the Taiyuan University of Science and Technology(20172014), the Shanxi Outstanding Doctorate Award Funding Fund (20182061) and the Coordinative Innovation Center of Taiyuan Heavy Machinery Equipment.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that there is no conflict of interest.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, J., Liu, C., Song, Y. et al. Influence of hot rolling + heat treatment on microstructure and mechanical properties of NM500/Q345/NM500 composite plate. J Mater Sci 56, 6016–6030 (2021). https://doi.org/10.1007/s10853-020-05666-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05666-4