Abstract

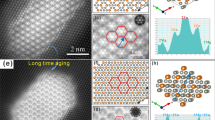

In this paper, we observe for the first time that a metastable beta-Zr in the body-centered cubic (BCC) structure can form via a new phase transformation route. The as-received alpha-Zr in the hexagonal closed-packed (HCP) structure transforms partially to the gamma-Zr in the face-centered cubic (FCC) structure via Shockley partial dislocations during deformation, while the gamma-Zr can continuously transform to the beta-Zr by a uniform shear along the \(\left\langle {112} \right\rangle_{{{\text{FCC}}}}\) direction on the \(\left\{ {111} \right\}_{{{\text{FCC}}}}\) plane during subsequent hot deformation. The beta phase is in a Pitsch–Schrader relationship \(((110)_{BCC}||(0001)_{HCP}, [1\overline{1}0]_{BCC}||[10\overline{1}0]_{HCP})\) with the matrix alpha phase and in a Nishiyama–Wassermann relationship \(((110)_{{{\text{BCC}}}} ||(1\overline{1}\overline{1})_{{{\text{FCC}}}} , [1\overline{1}0]_{{{\text{BCC}}}} ||[12\overline{1}]_{{{\text{FCC}}}} )\), with the gamma phase, both of which have not been reported in Zr previously. Combined with corresponding molecular dynamics simulations, the phase transition mechanism and stability of the beta phase are studied. The results show that the beta-Zr phase can be retained in the gamma phase when the cooling is fast enough.

Graphic abstract

Similar content being viewed by others

References

Cao Y, Ni S, Liao XZ, Song M, Zhu YT (2018) Structural evolutions of metallic materials processed by severe plastic deformation. Mater Sci Eng R-Rep 133:1–59

Lu WJ, Liebscher CH, Dehm G, Raabe D, Li ZM (2018) Bidirectional transformation enables hierarchical nanolaminate dual-phase high-entropy alloys. Adv Mater 30:1804727

Su J, Wu XX, Raabe D, Li ZM (2019) Deformation-driven bidirectional transformation promotes bulk nanostructure formation in a metastable interstitial high entropy alloy. Acta Mater 167:23–39

Pérez-Prado MT, Gimazov AA, Ruano OA, Kassner ME, Zhilyaev AP (2008) Bulk nanocrystalline ω-Zr by high-pressure torsion. Scripta Mater 58:219–222

Perez-Prado MT, Zhilyaev AP (2009) First experimental observation of shear induced hcp to bcc transformation in pure Zr. Phys Rev Lett 102:175504

Shen X, Yu PF, Jing Q, Yao Y, Gu L, Wang YG, Duan XF, Yu RC, Liu RP (2012) Transmission electron microscopy observations of structural modulation in the phase transition from α-Zr to ω-Zr induced by shear strain. Scripta Mater 67:653–656

Burgers WG (1934) On the process of transition of the cubic-body-centered modification into the hexagonal-close-packed modification of zirconium. Physica 1:561–586

Pitsch W, Schrader A (1958) Die Ausscheidungsform des ε-Karbids im Ferrit und im Martensit beim Anlassen. Archiv für das Eisenhüttenwesen 29:715–721

Matsukawa Y, Okuma I, Muta H et al (2017) Crystallographic analysis on atomic-plane parallelisms between bcc precipitates and hcp matrix in recrystallized Zr-2.5 Nb alloys. Acta Mater 126:86–101

Rong W, Dunlop GL (1984) The crystallography of secondary carbide precipitation in high speed steel. Acta Metall 32:1591–1599

Potter DL (1973) The structure, morphology and orientation relationship of V3N in α-vanadium. J Less Common Met 31:299–309

Hall MG, Aaronson HI, Kinsman KR (1972) The structure of nearly coherent fcc: bcc boundaries in a Cu-Cr alloy. Surf Sci 31:257–274

Nishiyama Z (1934) X-ray investigation of the mechanism of the transformation from face-centred to body-centred cubic lattice. Sci Rep Tohoku Imp Univ 23:637–664. (Cited by Hall MG, Aaronson HI, Kinsman KR (1972)The structure of nearly coherent fcc: bcc boundaries in a Cu-Cr alloy, Surf Sci 31:257–274).

Srinivasarao B, Zhilyaev AP, Perez-Prado MT (2011) Orientation dependency of the alpha to omega plus beta transformation in commercially pure zirconium by high-pressure torsion. Scripta Mater 65:241–244

Okunishi E, Kawai T, Mitsuhara M, Farjami S, Itakura M, Hara T, Nishida M (2013) HAADF-STEM studies of athermal and isothermal ω-phases in β-Zr alloy. J Alloys Compd 577:S713–S716

Zhao HL, Hu XY, Song M, Ni S (2017) Mechanisms for deformation induced hexagonal close-packed structure to face-centered cubic structure transformation in zirconium. Scripta Mater 132:63–67

An XL, Ni S, Song M (2019) Microstructural evolution and twinning behavior of a cold-rolled Zr70Ti30 alloy. J Alloys Compd 784:954–960

An XL, Zhang H, Ni S, Ou XQ, Liao XZ, Song M (2019) Effects of temperature and alloying content on the phase transformation and 1011 twinning in Zr during rolling. J Mater Sci Technol 41:76–80

Mendelev MI, Ackland GJ (2007) Development of an interatomic potential for the simulation of phase transformations in zirconium. Philos Mag Lett 87:349–359

Smith RW (2017) Atomistic simulation of martensitic transformations in zirconium nanoclusters. Comput Condens Matter 13:29

Dolgusheva EB, Trubitsin VY (2014) Study of size effects in structural transformations of bcc Zr films by molecular-dynamics simulation. Comput Mater Sci 84:23–30

Plimpton S (1995) Fast parallel algorithms for short-range molecular dynamics. J Comput Phys 117:1–19

Stukowski A (2009) Visualization and analysis of atomistic simulation data with OVITO–the open visualization tool. Modell Simul Mater Sci Eng 18:015012

Hu XY, Zhao HL, Ni S, Song M (2017) Grain refinement and phase transition of commercial pure zirconium processed by cold rolling. Mater Charact 129:149–155

Zhao HL, Song M, Ni S, Shao S, Wang J, Liao XZ (2017) Atomic-scale understanding of stress-induced phase transformation in cold-rolled Hf. Acta Mater 131:271–279

Sandoval L, Urbassek HM, Entel P (2009) The Bain versus Nishiyama-Wassermann path in the martensitic transformation of Fe. New J Phys 11:103027

Stukowski A (2012) Structure identification methods for atomistic simulations of crystalline materials. Modell Simul Mater Sci Eng 20:045021

Barrett CD, Kadiri HE (2014) Impact of deformation faceting on 1012}, {1011 and 1013 embryonic twin nucleation in hexagonal close-packed metals. Acta Mater 70:137–161

Zhang H, Ou XQ, Wei BQ, Ni S, Song M (2020) Strain direction dependency of deformation mechanisms in an HCP-Ti crystalline by molecular dynamics simulations. Comput Mater Sci 172:109328

Chen P, Wang F, Li B (2019) Transitory phase transformations during 1012 twinning in titanium. Acta Mater 171:65–78

Islam Z, Haque A (2018) Strain induced phase transformation in zirconium thin films. Comput Mater Sci 143:425–430

Tian ZA, Liu RS, Dong KJ (2011) A new method for analyzing the local structures of disordered systems. EPL 96:36001

Wu Z, Mo Y, Lang L (2008) Topologically close-packed characteristic of amorphous tantalum. Phys Chem Chem Phys 20:28088–28104

Zheng XD, Gong MY, Xiong T, Ge HL, Yang LX, Zhou YT, Zheng SJ, Wang J, Ma XL (2019) Deformation induced FCC lamellae and their interaction in commercial pure Ti. Scripta Mater 162:326–330

Fukino T, Tsurekawa S (2008) In-situ SEM/EBSD observation of α-γ phase transformation in Fe-Ni alloy. Mater Trans 49:2770–2775

Ou XQ, Song M (2019) Deformation mechanisms of mechanically induced phase transformations in iron. Comput Mater Sci 162:12–20

Yang XS, Sun S, Wu XL, Ma E, Zhang TY (2014) Dissecting the mechanism of martensitic transformation via atomic-scale observations. Sci Rep 4:6141

Yang XS, Sun S, Zhang TY (2015) The mechanism of bcc α′ nucleation in single hcp ε laths in the fcc γ→ hcp ε→ bcc α′ martensitic phase transformation. Acta Mater 95:264–273

Liu C, Li G, Gu H, Guo W (2020) Observation of fcc-Zr phase in as-cast zircaloy-4 alloy. Mater Lett 267:127551

Yang J, Zhao H, Gong H (2018) Proposed mechanism of HCP-FCC phase transition in titianium through first principles calculation and experiments. Sci Rep 8:1–9

Aguayo A, Murrieta G, de Coss R (2002) Elastic stability and electronic structure of fcc Ti, Zr, and Hf: A first-principles study. Phys Rev B 65:092106

Mo YF, Tian ZA, Liu RS, Hou ZY, Zhou LL, Peng P, Zhang HT, Liang YC (2016) Molecular dynamics study on microstructural evolution during crystallization of rapidly supercooled zirconium melts. J Alloys Compd 688:654–665

Smith RW (2017) Atomistic simulation of martensitic transformations in zirconium nanoclusters. Comput Condes Matter 13:29–35

Hunt CEL, Niessen P (1971) The continuous cooling transformation behaviour of zirconium-niobium-oxygen alloys. J Nucl Mater 38:17–25

Dumitraschkewitz P, Uggowitzer PJ, Gerstl SS, Löffler JF, Pogatscher S (2019) Size-dependent diffusion controls natural aging in aluminium alloys. Nat Commun 10:1–6

Dong QS, Saidi P, Yu HB, Yao ZW, Daymond MR (2019) A direct comparison of annealing in TEM thin foils and bulk material: application to Zr-2.5 Nb-0.5 Cu alloy. Mate Charact 151:175–181

Yu HB, Yao ZW, Long F, Saidi P, Daymond MR (2017) In situ transmission electron microscopy study of the thermally induced formation of δ′-ZrO in pure Zr and Zr-based alloy. J Appl Crystallogr 50:1028–1035

Traylor R, Zhang R, Kache J, Douglas JO, Bagot PA, Minor AM (2020) Impurity and texture driven HCP-to-FCC transformations in Ti-X thin films during in situ TEM annealing and FIB milling. Acta Mater 184:199–210

Acknowledgements

We would like to thank the financial support from Natural Science Foundation of China (51901248, 51828102), Natural Science Foundation of Hunan Province (2018JJ3649) and Project of Innovation-driven Plan in Central South University (2019CX026). The Advanced Research Center of Central South University is sincerely appreciated for TEM technical support.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Handling Editor: David Balloy.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Xinglong An and Keying An contribute equally to this work.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

An, X., An, K., Zhang, H. et al. A new phase transformation route for the formation of metastable beta-Zr. J Mater Sci 56, 2672–2683 (2021). https://doi.org/10.1007/s10853-020-05387-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05387-8