Abstract

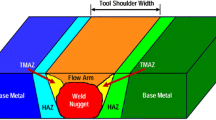

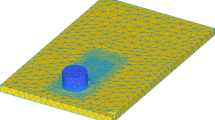

A procedure combining computational fluid dynamics modeling/Monte Carlo simulation was implemented to predict grain refinement during friction stir processing (FSP) of an Al–Mg alloy. Based on the critical parameters during FSP treatment such as rotational tool speed (w), and traverse velocity (v), the thermal and strain rate contours were simulated, and used as inputs for a statistical model of dynamic recrystallization. Afterward, the simulated grain structures were verified experimentally by electron backscattering diffraction analysis. FSP generated equiaxed grains with average sizes in the range of 3–10 µm depending on the heat input index in terms of w/v ratios in the range of 4–28 rev.min/mm. A correlation between simulated and experimentally validated grain structures is observed, with crystallographic textures consistent with shear strain induced preferred orientations with a dominant {112} <110> component.

Similar content being viewed by others

References

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R 50(1–2):1–78

Mishra RS, Ma ZY, Charit I (2003) Friction stir processing: a novel technique for fabrication of surface composite. Mater Sci Eng A 341(1–2):307–310

Khodabakhshi F, Gerlich AP (2018) Potentials and strategies of solid-state additive friction-stir manufacturing technology: a critical review. J Manuf Process 36:77–92

Khodabakhshi F, Marzbanrad B, Shah LH, Jahed H, Gerlich AP (2017) Friction-stir processing of a cold sprayed AA7075 coating layer on the AZ31B substrate: structural homogeneity, microstructures and hardness. Surf Coat Technol 331(Supplement C):116–128

Khodabakhshi F, Marzbanrad B, Shah LH, Jahed H, Gerlich AP (2019) Surface modification of a cold gas dynamic spray-deposited titanium coating on aluminum alloy by using friction-stir processing. J Therm Spray Technol 28(6):1185–1198

Khodabakhshi F, Marzbanrad B, Yazdanmehr A, Jahed H, Gerlich AP (2019) Tailoring the residual stress during two-step cold gas spraying and friction-stir surface integration of titanium coating. Surf Coat Technol 380:125008

Khodabakhshi F, Simchi A, Kokabi AH, Gerlich AP, Nosko M (2015) Effects of stored strain energy on restoration mechanisms and texture components in an aluminium–magnesium alloy prepared by friction stir processing. Mater Sci Eng A 642:204–214

Morishige T, Hirata T, Tsujikawa M, Higashi K (2010) Comprehensive analysis of minimum grain size in pure aluminum using friction stir processing. Mater Lett 64(17):1905–1908

Sharma V, Prakash U, Kumar BVM (2015) Surface composites by friction stir processing: a review. J Mater Process Technol 224:117–134

Ajay Kumar P, Madhu HC, Pariyar A, Perugu CS, Kailas SV, Garg U, Rohatgi P (2020) Friction stir processing of squeeze cast A356 with surface compacted graphene nanoplatelets (GNPs) for the synthesis of metal matrix composites. Mater Sci Eng A 769:138517

Xue P, Li WD, Wang D, Wang WG, Xiao BL, Ma ZY (2016) Enhanced mechanical properties of medium carbon steel casting via friction stir processing and subsequent annealing. Mater Sci Eng A 670:153–158

Khodabakhshi F, Ghasemi Yazdabadi H, Kokabi AH, Simchi A (2013) Friction stir welding of a P/M Al-Al2O3 nanocomposite: microstructure and mechanical properties. Mater Sci Eng A 585:222–232

Khodabakhshi F, Simchi A, Kokabi AH, Gerlich AP (2016) Similar and dissimilar friction-stir welding of an PM aluminum-matrix hybrid nanocomposite and commercial pure aluminum: microstructure and mechanical properties. Mater Sci Eng A 666:225–237

Khodabakhshi F, Simchi A, Kokabi AH, Gerlich AP, Nosko M, Švec P (2017) Influence of hard inclusions on microstructural characteristics and textural components during dissimilar friction-stir welding of an PM Al–Al2O3–SiC hybrid nanocomposite with AA1050 alloy. Sci Technol Weld Join 22(5):412–427

Khodabakhshi F, Gerlich A, Švec P (2017) Fabrication of a high strength ultra-fine grained Al–Mg–SiC nanocomposite by multi-step friction-stir processing. Mater Sci Eng A 698:313–325

Khodabakhshi F, Gerlich AP, Simchi A, Kokabi AH (2015) Cryogenic friction-stir processing of ultrafine-grained Al–Mg–TiO2 nanocomposites. Mater Sci Eng A 620:471–482

Zhang W, Ding H, Cai M, Yang W, Li J (2018) Ultra-grain refinement and enhanced low-temperature superplasticity in a friction stir-processed Ti–6Al–4V alloy. Mater Sci Eng A 727:90–96

Khodabakhshi F, Arab SM, Švec P, Gerlich AP (2017) Fabrication of a new Al–Mg/graphene nanocomposite by multi-pass friction-stir processing: dispersion, microstructure, stability, and strengthening. Mater Charact 132(Supplement C):92–107

Khodabakhshi F, Gerlich A, Švec P (2017) Reactive friction-stir processing of an Al–Mg alloy with introducing multi-walled carbon nano-tubes (MW-CNTs): microstructural characteristics and mechanical properties. Mater Charact 131:359–373

Khodabakhshi F, Gerlich AP, Simchi A, Kokabi AH (2015) Hot deformation behavior of an aluminum-matrix hybrid nanocomposite fabricated by friction stir processing. Mater Sci Eng A 626:458–466

Khodabakhshi F, Simchi A, Kokabi A, Nosko M, Švec P (2014) Strain rate sensitivity, work hardening, and fracture behavior of an Al–Mg TiO2 nanocomposite prepared by friction stir processing. Metall Mater Trans A 45(9):4073–4088

Khodabakhshi F, Simchi A, Kokabi AH, Nosko M, Simanĉik F, Švec P (2014) Microstructure and texture development during friction stir processing of Al–Mg alloy sheets with TiO2 nanoparticles. Mater Sci Eng A 605:108–118

Khodabakhshi F, Simchi A, Kokabi AH, Sadeghahmadi M, Gerlich AP (2015) Reactive friction stir processing of AA 5052–TiO2 nanocomposite: process–microstructure–mechanical characteristics. Mater Sci Technol 31(4):426–435

Khodabakhshi F, Simchi A, Kokabi AH, Švec P, Simančík F, Gerlich AP (2015) Effects of nanometric inclusions on the microstructural characteristics and strengthening of a friction-stir processed aluminium–magnesium alloy. Mater Sci Eng A 642:215–229

Ma ZY (2008) Friction stir processing technology: a review. Metall Mater Trans A 39(3):642–658

Nandan R, DebRoy T, Bhadeshia HKDH (2008) Recent advances in friction-stir welding—process, weldment structure and properties. Prog Mater Sci 53(6):980–1023

Zhang W, Ding H, Cai M, Yang W, Li J (2019) Low-temperature superplastic deformation mechanism in Ti–6Al–4V alloy processed by friction stir processing. Mater Sci Eng A 764:138261

Zhang W, Liu H, Ding H, Fujii H (2019) Grain refinement and superplastic flow in friction stir processed Ti–15V–3Cr–3Sn–3Al alloy. J Alloys Compd 803:901–911

McNelley TR, Swaminathan S, Su JQ (2008) Recrystallization mechanisms during friction stir welding/processing of aluminum alloys. Scr Mater 58(5):349–354

Sakai T, Belyakov A, Kaibyshev R, Miura H, Jonas JJ (2014) Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog Mater Sci 60:130–207

Khodabakhshi F, Nosko M, Gerlich AP (2018) Influence of CNTs decomposition during reactive friction-stir processing of an Al–Mg alloy on the correlation between microstructural characteristics and microtextural components. J Microsc 271(2):188–206

Khodabakhshi F, Nosko M, Gerlich AP (2018) Dynamic restoration and crystallographic texture of a friction-stir processed Al–Mg–SiC surface nanocomposite. Mater Sci Technol 34(14):1773–1791

Khodabakhshi F, Nosko M, Gerlich AP (2018) Effects of graphene nano-platelets (GNPs) on the microstructural characteristics and textural development of an Al–Mg alloy during friction-stir processing. Surf Coat Technol 335:288–305

Khodabakhshi F, Rahmati R, Nosko M, Orovčík L, Nagy Š, Gerlich AP (2019) Orientation structural mapping and textural characterization of a CP-Ti/HA surface nanocomposite produced by friction-stir processing. Surf Coat Technol 374:460–475

Khodabakhshi F, Simchi A, Kokabi AH, Nosko M, Simanĉik F, Švec P (2014) Microstructure and texture development during friction stir processing of Al–Mg alloy sheets with TiO2 nanoparticles. Mater Sci Eng A 605:108–118

Raabe D (1998) Computational materials science: the simulation of materials, microstructures and properties. Wiley, Hoboken

Aghajani Derazkola H, Khodabakhshi F (2019) Intermetallic compounds (IMCs) formation during dissimilar friction-stir welding of AA5005 aluminum alloy to St-52 steel: numerical modeling and experimental study. Int J Adv Manuf Technol 100(9):2401–2422

Derazkola HA, Khodabakhshi F, Simchi A (2018) Friction-stir lap-joining of aluminium–magnesium/poly-methyl-methacrylate hybrid structures: thermo-mechanical modelling and experimental feasibility study. Sci Technol Weld Join 23(1):35–49

Ansari MA, Samanta A, Behnagh RA, Ding H (2019) An efficient coupled Eulerian–Lagrangian finite element model for friction stir processing. Int J Adv Manuf Technol 101(5–8):1495–1508

Lipscomb CA, Fortier A, Kong F, Das S, Kumar N, Mishra RS (2016) Evaluation of plastic zone development in WE43 magnesium alloy upon friction stir processing using finite element modeling. Mater Sci Eng A 673:178–184

Goins PE, Holm EA (2016) The material point Monte Carlo model: a discrete, off-lattice method for microstructural evolution simulations. Comput Mater Sci 124:411–419

Homer ER, Tikare V, Holm EA (2013) Hybrid Potts-phase field model for coupled microstructural–compositional evolution. Comput Mater Sci 69:414–423

Luan Q, Lee J, Zheng JH, Hopper C, Jiang J (2020) Combining microstructural characterization with crystal plasticity and phase-field modelling for the study of static recrystallization in pure aluminium. Comput Mater Sci 173:109419

Yang CW, Tsou NT (2017) Microstructural analysis and molecular dynamics modeling of shape memory alloys. Comput Mater Sci 131:293–300

Fraser KA, St-Georges L, Kiss LI (2014) Optimization of friction stir welding tool advance speed via monte-carlo simulation of the friction stir welding process. Materials 7(5):3435–3452

Grujicic M, Ramaswami S, Snipes JS, Avuthu V, Galgalikar R, Zhang Z (2015) Prediction of the grain-microstructure evolution within a friction stir welding (FSW) joint via the use of the monte carlo simulation method. J Mater Eng Perform 24(9):3471–3486

Zhang Z, Hu CP (2018) 3D Monte Carlo simulation of grain growth in friction stir welding. J Mech Sci Technol 32(3):1287–1296

Zhang Z, Wu Q, Grujicic M, Wan ZY (2016) Monte Carlo simulation of grain growth and welding zones in friction stir welding of AA6082-T6. J Mater Sci 51(4):1882–1895. https://doi.org/10.1007/s10853-015-9495-x

Abdi Behnagh R, Samanta A, Agha Mohammad Pour M, Esmailzadeh P, Ding H (2019) Predicting microstructure evolution for friction stir extrusion using a cellular automaton method. Model Simul Mater Sci Eng 27(3):035006

Akbari M, Asadi P, Givi MB, Zolghadr P (2016) A cellular automaton model for microstructural simulation of friction stir welded AZ91 magnesium alloy. Model Simul Mater Sci Eng 24(3):035012

Asadi P, Givi MKB, Akbari M (2016) Simulation of dynamic recrystallization process during friction stir welding of AZ91 magnesium alloy. Int J Adv Manuf Technol 83(1–4):301–311

Saluja RS, Ganesh Narayanan R, Das S (2012) Cellular automata finite element (CAFE) model to predict the forming of friction stir welded blanks. Comput Mater Sci 58:87–100

Song KJ, Dong ZB, Fang K, Zhan XH, Wei YH (2014) Cellular automaton modelling of dynamic recrystallisation microstructure evolution during friction stir welding of titanium alloy. Mater Sci Technol 30(6):700–711

Wu Q, Zhang Z (2017) Precipitation-induced grain growth simulation of friction-stir-welded AA6082-T6. J Mater Eng Perform 26(5):2179–2189

Zhang Z, Tan ZJ, Li JY, Zu YF, Liu WW, Sha JJ (2019) Experimental and numerical studies of re-stirring and re-heating effects on mechanical properties in friction stir additive manufacturing. Int J Adv Manuf Technol 104(1–4):767–784

Yu Z, Zhang W, Choo H, Feng Z (2012) Transient heat and material flow modeling of friction stir processing of magnesium alloy using threaded tool. Metall Mater Trans A 43(2):724–737

Nandan R, Roy GG, Lienert TJ, Debroy T (2007) Three-dimensional heat and material flow during friction stir welding of mild steel. Acta Mater 55(3):883–895

Yang Z, Sista S, Elmer JW, DebRoy T (2000) Three dimensional Monte Carlo simulation of grain growth during GTA welding of titanium. Acta Mater 48(20):4813–4825

Huang CM, Joanne CL, Patnaik BSV, Jayaganthan R (2006) Monte Carlo simulation of grain growth in polycrystalline materials. Appl Surf Sci 252(11):3997–4002

Zhang Z, Wu Q, Zhang HW (2016) Prediction of fatigue life of welding tool in friction stir welding of AA6061-T6. Int J Adv Manuf Technol 86(9–12):3407–3415

Gao J, Thompson RG (1996) Real time-temperature models for Monte Carlo simulations of normal grain growth. Acta Mater 44(11):4565–4570

Driver GW, Johnson KE (2014) Interpretation of fusion and vaporisation entropies for various classes of substances, with a focus on salts. J Chem Thermodyn 70:207–213

Zhang Z, Zhang HW (2014) Solid mechanics-based Eulerian model of friction stir welding. Int J Adv Manuf Technol 72(9):1647–1653

Khodabakhshi F, Simchi A, Kokabi AH, Gerlich AP, Nosko M (2015) Effects of stored strain energy on restoration mechanisms and texture components in an aluminum–magnesium alloy prepared by friction stir processing. Mater Sci Eng A 642:204–214

Etter AL, Baudin T, Fredj N, Penelle R (2007) Recrystallization mechanisms in 5251 H14 and 5251 O aluminum friction stir welds. Mater Sci Eng A 445–446:94–99

Jata KV, Semiatin SL (2000) Continuous dynamic recrystallization during friction stir welding of high strength aluminum alloys. Scr Mater 43(8):743–749

Fonda RW, Knipling KE (2011) Texture development in friction stir welds. Sci Technol Weld Join 16(4):288–294

Yoon S, Ueji R, Fujii H (2015) Effect of rotation rate on microstructure and texture evolution during friction stir welding of Ti–6Al–4V plates. Mater Charact 106:352–358

Reynolds AP, Hood E, Tang W (2005) Texture in friction stir welds of Timetal 21S. Scr Mater 52(6):491–494

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that this work has no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khodabakhshi, F., Derazkola, H.A. & Gerlich, A.P. Monte Carlo simulation of grain refinement during friction stir processing. J Mater Sci 55, 13438–13456 (2020). https://doi.org/10.1007/s10853-020-04963-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04963-2