Abstract

The Mg–Zn–Ca–Sr alloy has good application prospects as a bone implant material; however, the as-cast alloy has both poor plasticity and formability, and there are few studies on its deformation properties. In this study, the microstructure, deformation behavior, textural evolution, and processing map of an Mg–3wt%Zn–1wt%Ca–0.5wt%Sr alloy were studied via a compression test using a Gleeble 1500D thermo-mechanical simulator. The mean apparent activation energy of the hot compression deformation of the Mg–3wt%Zn–1wt%Ca–0.5wt%Sr alloy was 250.44 kJ/mol. With an increase in temperature, both the grain size and the degree of dynamic recrystallization increased. Dynamically recrystallized grains predominantly nucleated near the grain boundary and the secondary phases. After compression, the alloy had a strong basal texture, and its textural strength decreased at first and then increased slightly as the deformation temperature rose. The optimal process parameters of the as-cast Mg–Zn–Ca–Sr alloy involved deformation temperatures of 603–633 K and strain rates of 0.03–0.005 s–1.

Similar content being viewed by others

References

He G, Wu Y, Zhang Y, Zhu Y, Liu Y, Li N (2015) Addition of Zn to the ternary Mg–Ca–Sr alloys significantly improves their antibacterial properties. J Mater Chem B 3(32):6676–6689

Bornapour M, Muja N, Shum-Tim D, Cerruti M, Pekguleryuz M (2013) Biocompatibility and biodegradability of Mg–Sr alloys: the formation of Sr-substituted hydroxyapatite. Acta Biomater 9(2):5319–5330

Wu Y, He G, Liu Y, Li M, Wang X (2016) Unique antitumor property of the Mg–Ca–Sr alloys with addition of Zn. Sci Reports 6:21736. https://doi.org/10.1038/srep21736

Yu YD, Zhang KF, Jiang DM, Zheng HR, Wang CL (2003) Superplasticity and superplastic bulging capability of rolled magnesium alloy. Chin J Nonferrous Metals(China) 13(1):71–75

Liu CM, Liu ZJ, Zhu XR, Zhou HT (2006) Research and development progress of dynamic recrystallization in pure magnesium and its alloys. Chin J Nonferrous Metals 16(1):1–12

Xi BL, Fang G (2017) Crystal plasticity behavior of single-crystal pure magnesium under plane-strain compression. Rare Met 36(7):541–549

Lv BJ, Peng J, Wang YJ, An XQ, Zhong LP, Tang AT, Pan FS (2014) Dynamic recrystallization behavior and hot workability of Mg–2.0 Zn–0.3 Zr–0.9 Y alloy by using hot compression test. Mater Des 53:357–365

Qiu X, Yang Q, Guan K, Bu F, Cao ZY, Liu YB, Meng J (2017) Microstructures and tensile properties of Mg–Zn–(Gd)–Zr alloys extruded at various temperatures. Rare Met 36(12):962–970

Borkar H, Pekguleryuz M (2013) Microstructure and texture evolution in Mg–1% Mn–Sr alloys during extrusion. J Mater Sci 48(4):1436–1447. https://doi.org/10.1007/s10853-012-6896-y

Li JQ, Liu J, Cui ZS (2017) 3D processing map for hot working of extruded AZ80 magnesium alloy. Rare Met 36(1):10–17

Lin YC, Chen XM (2011) A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater Des 32(4):1733–1759

Xu Y, Hu L, Sun Y (2013) Processing map and kinetic analysis for hot deformation of an as-cast AZ91D magnesium alloy. Mater Sci Eng, A 578:402–407

Qin YJ, Pan QL, He YB, Li WB, Liu XY, Fan X (2010) Modeling of flow stress for magnesium alloy during hot deformation. Mater Sci Eng A 527(10-11):2790–2797

Chen Q, Xia X, Yuan B, Shu D, Zhao Z, Han J (2014) Hot workfability behavior of as-cast Mg–Zn–Y–Zr alloy. Mater Sci Eng A 593:38–47

Xia X, Chen Q, Huang S, Lin J, Hu C, Zhao Z (2015) Hot deformation behavior of extruded Mg–Zn–Y–Zr alloy. J Alloy Compd 644:308–316

Malik A, Wang Y, Huanwu C, Nazeer F, Ahmed B, Khan MA, Mingjun W (2020) Constitutive analysis, twinning, recrystallization, and crack in fine-grained ZK61 Mg alloy during high strain rate compression over a wide range of temperatures. Mater Sci Eng A 771:138649. https://doi.org/10.1016/j.msea.2019.138649

Moon BG, You BS, Hahn YD (2014) Effects of aluminum and strontium content on the microstructures and mechanical properties of Mg-Al-Ca-Sr alloys. Current Nanosci 10(1):108–113

Lu Y, Bradshaw AR, Chiu YL, Jones IP (2015) Effects of secondary phase and grain size on the corrosion of biodegradable Mg–Zn–Ca alloys. Mater Sci Eng C 48:480–486

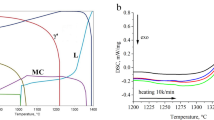

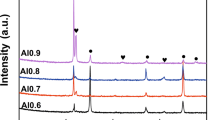

Liu HN, Zhang K, Yuan JW, Li YJ, Li XG, Ma ML, Shi GL, Wang KK (2020) In vitro degradation behavior of as-cast Mg-3Zn-1Ca-0.5Sr alloy. Mater Res Express. https://doi.org/10.1088/2053-1591/ab6e2c

Liu HN, Zhang K, Yuan JW, Li YJ, Li XG, Ma ML, Shi GL, Wang KK (2020) Microstructure and corrosion resistance of bone-implanted Mg–Zn–Ca–Sr alloy under different cooling methods. Rare Met. https://doi.org/10.1007/s12598-020-01368-7

Zhang L, Wang Q, Liu G, Guo W, Jiang H, Ding W (2017) Effect of SiC particles and the particulate size on the hot deformation and processing map of AZ91 magnesium matrix composites. Mater Sci Eng, A 707:315–324

Wasiur-Rahman S, Medraj M (2009) Critical assessment and thermodynamic modeling of the binary Mg–Zn, Ca–Zn and ternary Mg–Ca–Zn systems. Intermetallics 17(10):847–864

Ding R, Guo ZX (2001) Coupled quantitative simulation of microstructural evolution and plastic flow during dynamic recrystallization. Acta Mater 49(16):3163–3175

Wu H, Yang J, Liao J, Zhu FJ (2012) Dynamic behavior of extruded AZ61 Mg alloy during hot compression. Mater Sci Eng, A 535:68–75

Sellars CM, McTegart WJ (1966) On the mechanism of hot deformation. Acta Metall 14(9):1136–1138

Gu XN, Xie XH, Li N, Zheng YF, Qin L (2012) In vitro and in vivo studies on a Mg–Sr binary alloy system developed as a new kind of biodegradable metal. Acta Biomater 8(6):2360–2374

Li M (2016) Study on the microstructures and properties of Mg–Gd–Y–Nd–Zn based alloys containing long-period stacking ordered phase. PhD Dissertation, General Research Institute for Nonferrous Metals.

Vogel M, Kraft O, Dehm G, Arzt E (2001) Quasi-crystalline grain-boundary phase in the magnesium die-cast alloy ZA85. Scripta Mater 45(5):517–524

Yu SL, Gao YH, Liu CM, Xiao HC (2016) Dynamic recrystallization behavior of Mg-Gd-Y-Zr alloy during hot compression. Mater Sci Forum 849:181–185

Fatemi-Varzaneh SM, Zarei-Hanzaki A, Beladi H (2007) Dynamic recrystallization in AZ31 magnesium alloy. Mater Sci Eng, A 456(1-2):52–57

Galiyev A, Kaibyshev R, Gottstein G (2001) Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60. Acta Mater 49(7):1199–1207

Vaughan MW, Nasim W, Dogan E, Herrington JS, Proust G, Benzerga AA, Karaman I (2019) Interplay between the effects of deformation mechanisms and dynamic recrystallization on the failure of Mg-3Al-1Zn. Acta Mater 168:448–472

Yang X, Miura H, Sakai T (2003) Dynamic evolution of new grains in magnesium alloy AZ31 during hot deformation. Mater Trans 44(1):197–203

Al-Samman T, Gottstein G (2008) Dynamic recrystallization during high temperature deformation of magnesium. Mater Sci Eng A 490(1-2):411–420

Bisht A, Kamble N, Kumar L, Avadhani GS, Roy A, Silberschmidt V, Suwas S (2019) Deformation response and microstructural evolution of as-cast Mg alloys AM30 and AM50 during hot compression. Int J Mater Res 110(6):524–533

Zhang D, Yang X, Sun H, Li Y, Wang J, Zhang Z, Ye Y, Sakai T (2015) Dynamic recrystallization behaviors and the resultant mechanical properties of a mg-y-nd-zr alloy during hot compression after aging. Mater Sci Eng 640(29):51–60

Guo F, Zhang D, Fan X, Jiang L, Yu D, Pan F (2016) Deformation behavior of az31 mg alloys sheet during large strain hot rolling process: a study on microstructure and texture evolutions of an intermediate-rolled sheet. J Alloy Compd 663:140–147

Qing LIU (2010) Research progress on plastic deformation mechanism of Mg alloys. Acta Metall Sin 46(11):1458–1472

Guo Y, Xuanyuan Y, Lia C, Yang S (2019) Characterization of hot deformation behavior and processing maps of Mg-3Sn-2Al-1Zn-5Li magnesium alloy. Metals 9(12):1262. https://doi.org/10.3390/met9121262

Acknowledgments

The authors acknowledge the staff at GRIMAT Engineering institute Co., Ltd for their time and instrument use. Thanks GRINM Analysis and Testing Center at for their Electron Microscopy use, also thanks my teachers and classmates for their help.

Funding

The authors thank Jiangsu Province Achievement Transformation Project: BA2017044.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, H., Li, Y., Zhang, K. et al. Microstructure, hot deformation behavior, and textural evolution of Mg–3wt%Zn–1wt%Ca–0.5wt%Sr Alloy. J Mater Sci 55, 12434–12447 (2020). https://doi.org/10.1007/s10853-020-04817-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04817-x