Abstract

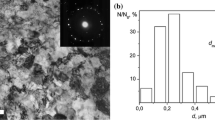

In the paper, we study the evolution of the structural phase state, deformation behavior, and fracture of ultrafine-grained near-β titanium alloy Ti–5Al–5Mo–5V–1Cr–1Fe after annealing in the temperature range 773–1073 K (0.4–0.55 Tm). The duration of the strain-hardening stage under tensile conditions is shown to be almost independent of the annealing temperature. The character of the strain-softening stage is largely determined by the alloy structure formed after annealing. It is found that annealing at the temperatures 773 and 873 K does not change the deformation behavior of the ultrafine-grained alloy under tension at room temperature. Deformation and fracture of the specimens localize in shear bands. Recrystallization occurring at the annealing temperature 973 and 1073 K leads to the transition of grain boundaries to a more equilibrium state and to a sharp decrease in strength and softening rate of the titanium alloy. It also affects the neck formation prior to fracture, giving a developed neck. Fracture surfaces are indicative of ductile dimple fracture of the alloy in all states. The dimple size depends on the size of structural elements after heat treatments. Based on the experimental data, the σ0 value and Hall–Petch coefficient k are determined. In the investigated grain size range (0.17–1.25 μm) the values are found to be, respectively, 680 MPa and 0.36 MPa m1/2.

Similar content being viewed by others

References

Ovid’ko IA, Valiev RZ, Zhu YT (2018) Review on superior strength and enhanced ductility of metallic nanomaterials. Prog Mater Sci 94:462–540

Kolobov Y, Valiev RZ, Grabovetskaya GP, Zhilyaev AP, Dudarev EF, Ivanov KV, Ivanov MB, Kashin OA, Naydenkin EV (2007) Grain boundary diffusion and properties of nanostructured materials. Cambridge International Science Publishing, Cambridge

Morris DG (1998) Mechanical behaviour of nanostructured materials. Trans Tech Publication ltd, Switzerland

Meyers MA, Mishra A, Benson DJ (2006) Mechanical properties of nanocrystalline materials. Prog Mater Sci 51:427–556

Sabirov I, Enikeev NA, Murashkin MY, Valiev RZ (2015) Bulk nanostructured materials with multifunctional properties. Springer, New York

Nazarov AA, Romanov AE, Valiev RZ (1993) On the structure, stress fields and energy of nonequilibrium grain boundaries. Acta Metall Mater 41:1033–1040

Divinski SV, Reglitz G, Rösner H, Estrin Y, Wilde G (2011) Ultra-fast diffusion channels in pure Ni severely deformed by equal-channel angular pressing. Acta Mater 59(5):1974–1985

Sauvage X, Wilde G, Divinski SV, Horita Z, Valiev RZ (2012) Grain boundaries in ultrafine grained materials processed by severe plastic deformation and related phenomena. Mater Sci Eng A 540:1–12

Kolobov Y, Grabovetskaya GP, Ivanov MB, Zhilyaev AP, Valiev RZ (2001) Grain boundary diffusion characteristics of nanostructured nickel. Scr Mat 44:873–878

Yamashita A, Horita Z, Langdon TG (2001) Improving the mechanical properties of magnesium and a magnesium alloy through severe plastic deformation. Mater Sci Eng A 300(1–2):142–147

Pande C, Cooper K (2009) Nanomechanics of Hall–Petch relationship in nanocrystalline materials. Prog Mater Sci 54(6):689–706

Schafler E, Kerber MB (2007) Microstructural investigation of the annealing behavior of high-pressure torsion (HPT) deformed copper. Mater Sci Eng A 462(1–2):139–143

Valiev RZ, Langdon TG (2010) The art and science of tailoring materials by nanostructuring for advanced properties using SPD techniques. Adv Eng Mater 12(8):677–691

Chuvil’deev VN, Nokhrin AV, Lopatin YG, Kozlova NA, Piskunov AV, Melekhina NV, Kopylov VI, Bakhmetev AM, Sandler NG, Tryaev PV (2012) Effect of the simultaneous enhancement in strength and corrosion resistance of microcrystalline titanium alloys. Dokl Phys 57(1):10–13

Naydenkin EV, Ratochka IV, Mishin IP, Lykova ON, Varlamova NV (2017) The effect of interfaces on mechanical and superplastic properties of titanium alloys. J Mater Sci 52(8):4164–4171. https://doi.org/10.1007/s10853-016-0508-1

Ratochka IV, Naydenkin EV, Lykova ON, Mishin IP (2018) Regularities in superplasticity of titanium alloys in relation to their initial structure and phase composition. Lett Mat 8(4):543–548

Il’in AA, Kolachev BA, Pol’kin IS (2009) Titanium alloys. Composition, structure, properties. Ref book, VILS–MATI, Moscow, p 520 (in Russian)

Vinokurov VA, Naydenkin EV, Ratochka IV, Kolobov YR, Rozhintceva NV (2008) Method of obtaining a material with an ultrafine-grained or submicrocrystalline structure by strain with severe plastic deformation (options). Patent RF 2334582 (in Russian)

Gunderov DV, Polyakov AV, Semenova IP, Raab GI, Churakova AA, Gimaltdinova EI, Sabirov I, Segurado J, Sitdikov VD, Alexandrov IV, Enikeev NA, Valiev RZ (2013) Evolution of microstructure, macrotexture and mechanical properties of commercially pure Ti during ECAP-conform processing and drawing. Mater Sci Eng A 562:128–136

Rollett A, Humphreys F, Rohrer GS, Hatherly M (2004) Recrystallization and related annealing phenomena, 2nd edn. Elsevier, Oxford

Jia D, Wang YM, Ramesh KT, Ma E, Zhu YT, Valiev RZ (2001) Deformation behavior and plastic instabilities of ultrafine-grained titanium. Appl Phys Lett 79:611–613

Li Z, Wang B, Zhao S, Valiev RZ, Vecchio KS, Meyers MA (2017) Dynamic deformation and failure of ultrafine-grained titanium. Acta Mater 125:210–218

Naydenkin EV, Grabovetskaya GP (2010) Deformation behavior and plastic strain localization of nanostructured materials produced by severe plastic deformation. Mater Sci For 633–634:107–119

Zherebtsov S, Kudryavtsev E, Kostjuchenko S, Malysheva S, Salishchev G (2012) Strength and ductility-related properties of ultrafine grained two-phase titanium alloy produced by warm multiaxial forging. Mater Sci Eng A 536:190–196

Li Z, Zhao S, Wang B, Cui S, Chen R, Valiev RZ, Meyers MA (2019) The effects of ultra-fine-grained structure and cryogenic temperature on adiabatic shear localization in titanium. Acta Mater 181:408–422

Luo P, McDonald DT, Xu W, Palanisamy S, Dargusch MS, Xia K (2012) A modified Hall–Petch relationship in ultrafine-grained titanium recycled from chips by equal channel angular pressing. Scripta Mater 66:785–788

Chuvil’deev VN, Kopylov VI, Nokhrin AV, Tryaev PV, Kozlova NA, Tabachkova NY, Lopatin Y, Ershova AV, Mikhaylov AS, Gryaznov MYu, Chegurov MK (2017) Study of mechanical properties and corrosive resistance of ultrafine-grained alpha-titanium alloy Ti–5Al–2V. J Alloys Compd 723:354–367

Chao Q, Hodgson PD, Beladi H (2017) Thermal stability of an ultrafine grained Ti–6Al–4V alloy during post-deformation annealing. Mater Sci Eng A 694:13–23

Moiseyev VN (2005) Titanium alloys. Russian aircraft and aerospace applications. CRC Press, New York

Liebowitz H (1969) In: Liebowitz H (ed) Fracture of metals. Elsevier, Amsterdam. https://doi.org/10.1016/C2013-0-11089-6

Acknowledgements

This work was supported by the Russian Science Foundation (Project No. 19-19-00033).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Naydenkin, E.V., Ratochka, I.V., Lykova, O.N. et al. Evolution of the structural phase state, deformation behavior, and fracture of ultrafine-grained near-β titanium alloy after annealing. J Mater Sci 55, 9237–9244 (2020). https://doi.org/10.1007/s10853-020-04468-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04468-y