Abstract

The predictive modeling of the experimentally observed behavior of metallic materials under shock loading conditions (wave structures, spall strengths) is a critical challenge toward the design of next-generation structural materials. This challenge is due to the lack of computational methods that can predict microstructural evolution at the mesoscales under dynamic loading conditions. While classical molecular dynamics simulations have been able to provide atomic-scale insights in the defect and damage nucleation/evolution mechanisms, the capability to have a direct comparison with experimental data at the same time and length scales is still a challenge. The current computational approaches require that several approximations be made either for the loading conditions or for the micromechanisms related to defect evolution and interaction at the mesoscales. This viewpoint discusses the insights obtained from molecular dynamics simulations of shock deformation and spall failure of heterogeneous metallic microstructures. An example Al–Ni microstructure is used to identify the critical atomic-scale phenomena that need to be addressed by the mesoscale methods when considering shock deformation and failure (spallation) at the mesoscales.

Similar content being viewed by others

References

Dinda GP, Dasgupta AK, Mazumder J (2012) Texture control during laser deposition of nickel-based superalloy. Scripta Mater 67:503. https://doi.org/10.1016/j.scriptamat.2012.06.014

Beyerlein IJ, Mayeur JR, Zheng S, Mara NA, Wang J, Misra A (2014) Emergence of stable interfaces under extreme plastic deformation. Proc Natl Acad Sci 111:4386. https://doi.org/10.1073/pnas.1319436111

Sun Y, Aindow M, Hebert RJ, Langdon TG, Lavernia EJ (2017) High-pressure torsion-induced phase transformations and grain refinement in Al/Ti composites. J Mater Sci 52:12170. https://doi.org/10.1007/s10853-017-1331-z

Geslin P-A, McCue I, Gaskey B, Erlebacher J, Karma A (2015) Topology-generating interfacial pattern formation during liquid metal dealloying. Nat Commun 6:8887. https://doi.org/10.1038/ncomms9887

Wei CT, Vitali E, Jiang F et al (2012) Quasi-static and dynamic response of explosively consolidated metal–aluminum powder mixtures. Acta Mater 60:1418. https://doi.org/10.1016/j.actamat.2011.10.027

Xiong W, Zhang X, Zheng L, Bao K, Chen H, Guan Z (2019) The shock-induced chemical reaction behaviour of Al/Ni composites by cold rolling and powder compaction. J Mater Sci 54:6651. https://doi.org/10.1007/s10853-019-03357-3

Han WZ, Cerreta EK, Mara NA et al (2014) Deformation and failure of shocked bulk Cu–Nb nanolaminates. Acta Mater 63:150. https://doi.org/10.1016/j.actamat.2013.10.019

Beets N, Cui Y, Farkas D, Misra A (2019) Mechanical response of a bicontinuous copper–molybdenum nano-composite: experiments and simulations. Acta Mater 178:79. https://doi.org/10.1016/j.actamat.2019.07.045

McDowell DL (2010) A perspective on trends in multiscale plasticity. Int J Plast 26:1280. https://doi.org/10.1016/j.ijplas.2010.02.008

Clayton JD (2018) Mesoscale models of interface mechanics in crystalline solids: a review. J Mater Sci 53:5515. https://doi.org/10.1007/s10853-017-1596-2

Lloyd JT, Clayton JD, Becker R, McDowell DL (2014) Simulation of shock wave propagation in single crystal and polycrystalline aluminum. Int J Plast 60:118. https://doi.org/10.1016/j.ijplas.2014.04.012

Clayton JD (2017) Mesoscale models of interface mechanics in crystalline solids: a review. J Mater Sci. https://doi.org/10.1007/s10853-017-1596-2

Vogler TJ, Clayton JD (2008) Heterogeneous deformation and spall of an extruded tungsten alloy: plate impact experiments and crystal plasticity modeling. J Mech Phys Solids 56:297. https://doi.org/10.1016/j.jmps.2007.06.013

Becker R (2004) Effects of crystal plasticity on materials loaded at high pressures and strain rates. Int J Plast 20:1983. https://doi.org/10.1016/j.ijplas.2003.09.002

Clayton JD (2005) Modeling dynamic plasticity and spall fracture in high density polycrystalline alloys. Int J Solids Struct 42:4613. https://doi.org/10.1016/j.ijsolstr.2005.02.031

Feng B, Bronkhorst CA, Addessio FL et al (2019) Coupled nonlinear elasticity, plastic slip, twinning, and phase transformation in single crystal titanium for plate impact loading. J Mech Phys Solids 127:358. https://doi.org/10.1016/j.jmps.2019.03.019

Dongare AM, LaMattina B, Rajendran AM (2011) Atomic scale studies of spall behavior in single crystal Cu. Proc Eng 10:3636. https://doi.org/10.1016/j.proeng.2011.04.598

Zepeda-Ruiz LA, Stukowski A, Oppelstrup T, Bulatov VV (2017) Probing the limits of metal plasticity with molecular dynamics simulations. Nature 550:492. https://doi.org/10.1038/nature23472

Chen J, Tschopp MA, Dongare AM (2017) Role of nanoscale Cu/Ta interfaces on the shock compression and spall failure of nanocrystalline Cu/Ta systems at the atomic scales. J Mater Sci. https://doi.org/10.1007/s10853-017-1879-7

Chen J, Tschopp MA, Dongare AM (2017) Shock wave propagation and spall failure of nanocrystalline Cu/Ta alloys: effect of Ta in solid-solution. J Appl Phys 122:225901. https://doi.org/10.1063/1.5001761

Chen J, Mathaudhu SN, Thadhani N, Dongare AM (2019) Correlations between dislocation density evolution and spall strengths of Cu/Ta multilayered systems at the atomic scales: the role of spacing of KS interfaces. Materialia 5:100192. https://doi.org/10.1016/j.mtla.2018.100192

Galitskiy S, Ivanov DS, Dongare AM (2018) Dynamic evolution of microstructure during laser shock loading and spall failure of single crystal Al at the atomic scales. J Appl Phys 124:205901

Zhang RF, Germann TC, Liu XY, Wang J, Beyerlein IJ (2014) Layer size effect on the shock compression behavior of fcc–bcc nanolaminates. Acta Mater 79:74. https://doi.org/10.1016/j.actamat.2014.07.016

Hahn EN, Germann TC, Ravelo R, Hammerberg JE, Meyers MA (2017) On the ultimate tensile strength of tantalum. Acta Mater 126:313. https://doi.org/10.1016/j.actamat.2016.12.033

Agarwal G, Dongare AM (2016) Shock wave propagation and spall failure in single crystal Mg at atomic scales. J Appl Phys 119:145901. https://doi.org/10.1063/1.4944942

Zhigilei LV, Volkov AN, Dongare AM (2012) Computational study of nanomaterials: from large-scale atomistic simulations to mesoscopic modeling. In: Bhushan B (ed) Encyclopedia of nanotechnology, part 4. Springer, Dordrecht, p 470

Sliwa M, McGonegle D, Wehrenberg C et al (2018) Femtosecond X-ray diffraction studies of the reversal of the microstructural effects of plastic deformation during shock release of tantalum. Phys Rev Lett 120:265502. https://doi.org/10.1103/PhysRevLett.120.265502

Turneaure SJ, Renganathan P, Winey JM, Gupta YM (2018) Twinning and dislocation evolution during shock compression and release of single crystals: real-time X-ray diffraction. Phys Rev Lett 120:265503. https://doi.org/10.1103/PhysRevLett.120.265503

Lind J, Jensen BJ, Barham M, Kumar M (2018) In situ dynamic compression wave behavior in additively manufactured lattice materials. J Mater Res 34:2. https://doi.org/10.1557/jmr.2018.351

Jensen BJ, Gray GT III, Hixson RS (2009) Direct measurements of the α–ϵ transition stress and kinetics for shocked iron. J Appl Phys 105:103502. https://doi.org/10.1063/1.3110188

Smith RF, Eggert JH, Rudd RE, Swift DC, Bolme CA, Collins GW (2011) High strain-rate plastic flow in Al and Fe. J Appl Phys 110:123515. https://doi.org/10.1063/1.3670001

Smith RF, Eggert JH, Swift DC et al (2013) Time-dependence of the alpha to epsilon phase transformation in iron. J Appl Phys 114:223507. https://doi.org/10.1063/1.4839655

Crowhurst JC, Reed BW, Armstrong MR et al (2014) The α → ϵ phase transition in iron at strain rates up to ∼ 109 s−1. J Appl Phys 115:113506. https://doi.org/10.1063/1.4868676

Purja Pun GP, Mishin Y (2009) Development of an interatomic potential for the Ni–Al system. Philos Mag 89:3245. https://doi.org/10.1080/14786430903258184

Dongare AM, LaMattina B, Irving DL, Rajendran AM, Zikry MA, Brenner DW (2012) An angular-dependent embedded atom method (A-EAM) interatomic potential to model thermodynamic and mechanical behavior of Al/Si composite materials. Model Simul Mater Sci Eng 20:035007

Purja Pun GP, Darling KA, Kecskes LJ, Mishin Y (2015) Angular-dependent interatomic potential for the Cu–Ta system and its application to structural stability of nano-crystalline alloys. Acta Mater 100:377. https://doi.org/10.1016/j.actamat.2015.08.052

Winey JM, LaLone BM, Trivedi PB, Gupta YM (2009) Elastic wave amplitudes in shock-compressed thin polycrystalline aluminum samples. J Appl Phys 106:073508. https://doi.org/10.1063/1.3236654

Gupta YM, Winey JM, Trivedi PB et al (2009) Large elastic wave amplitude and attenuation in shocked pure aluminum. J Appl Phys 105:036107. https://doi.org/10.1063/1.3075839

Gurrutxaga-Lerma B, Shehadeh MA, Balint DS, Dini D, Chen L, Eakins DE (2017) The effect of temperature on the elastic precursor decay in shock loaded FCC aluminium and BCC iron. Int J Plast 96:135. https://doi.org/10.1016/j.ijplas.2017.05.001

Grady DE (1988) The spall strength of condensed matter. J Mech Phys Solids 36:353. https://doi.org/10.1016/0022-5096(88)90015-4

Kanel GI, Razorenov SV, Bogatch A, Utkin AV, Fortov VE, Grady DE (1996) Spall fracture properties of aluminum and magnesium at high temperatures. J Appl Phys 79:8310. https://doi.org/10.1063/1.362542

Meyers MA, Chawla KK (2008) Mechanical behavior of materials. Cambridge University Press, Cambridge

Remington TP, Hahn EN, Zhao S et al (2018) Spall strength dependence on grain size and strain rate in tantalum. Acta Mater 158:313. https://doi.org/10.1016/j.actamat.2018.07.048

Lieberman EJ, Lebensohn RA, Menasche DB, Bronkhorst CA, Rollett AD (2016) Microstructural effects on damage evolution in shocked copper polycrystals. Acta Mater 116:270. https://doi.org/10.1016/j.actamat.2016.06.054

Remington TP, Remington BA, Hahn EN, Meyers MA (2017) Deformation and failure in extreme regimes by high-energy pulsed lasers: a review. Mater Sci Eng A 688:429. https://doi.org/10.1016/j.msea.2017.01.114

Medlin DL, Carter CB, Angelo JE, Mills MJ (1997) Climb and glide of a/3 <111> dislocations in an aluminium Σ = 3 boundary. Philos Mag A 75:733. https://doi.org/10.1080/01418619708207199

Campbell GH, Chan DK, Medlin DL, Angelo JE, Carter CB (1996) Dynamic observation of the fcc to 9r shear transformation in a copper ∑ = 3 incoherent twin boundary. Scripta Mater 35:837. https://doi.org/10.1016/1359-6462(96)00220-5

Janish MT, Kotula PG, Boyce BL, Carter CB (2015) Observations of fcc and hcp tantalum. J Mater Sci 50:3706. https://doi.org/10.1007/s10853-015-8931-2

Janish MT, Mook WM, Carter CB (2015) Nucleation of fcc Ta when heating thin films. Scripta Mater 96:21. https://doi.org/10.1016/j.scriptamat.2014.10.010

Remington BA, Bazan G, Belak J et al (2004) Materials science under extreme conditions of pressure and strain rate. Metal Mater Trans A 35:2587. https://doi.org/10.1007/s11661-004-0205-6

Lubarda VA, Schneider MS, Kalantar DH, Remington BA, Meyers MA (2004) Void growth by dislocation emission. Acta Mater 52:1397. https://doi.org/10.1016/j.actamat.2003.11.022

Bober DB, Lind J, Mulay RP, Rupert TJ, Kumar M (2017) The formation and characterization of large twin related domains. Acta Mater 129:500. https://doi.org/10.1016/j.actamat.2017.02.051

Briggs R, Coppari F, Gorman MG et al (2019) Measurement of body-centered cubic gold and melting under shock compression. Phys Rev Lett 123:045701. https://doi.org/10.1103/PhysRevLett.123.045701

Leong AFT, Robinson AK, Fezzaa K et al (2018) Quantitative in situ studies of dynamic fracture in brittle solids using dynamic X-ray phase contrast imaging. Exp Mech 58:1423. https://doi.org/10.1007/s11340-018-0414-3

Hawreliak JA, Lind J, Maddox B et al (2016) Dynamic behavior of engineered lattice materials. Sci Rep 6:28094. https://doi.org/10.1038/srep28094

Dongare AM (2014) Quasi-coarse-grained dynamics: modelling of metallic materials at mesoscales. Philos Mag 94:3877. https://doi.org/10.1080/14786435.2014.961992

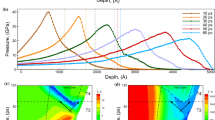

Agarwal G, Valisetty RR, Namburu RR, Rajendran AM, Dongare AM (2017) The quasi-coarse-grained dynamics method to unravel the mesoscale evolution of defects/damage during shock loading and spall failure of polycrystalline Al microstructures. Sci Rep 7:12376. https://doi.org/10.1038/s41598-017-12340-4

Agarwal G, Dongare AM (2018) Defect and damage evolution during spallation of single crystal Al: comparison between molecular dynamics and quasi-coarse-grained dynamics simulations. Comput Mater Sci 145:68. https://doi.org/10.1016/j.commatsci.2017.12.032

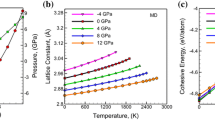

Agarwal G, Dongare AM (2017) Modeling the thermodynamic behavior and shock response of Ti systems at the atomic scales and the mesoscales. J Mater Sci 52:10853. https://doi.org/10.1007/s10853-017-1243-y

Acknowledgements

This material is based upon the work supported by the Department of Energy, National Nuclear Security Administration under Award No. DE-NA0003857. Any opinions, findings, and conclusions or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the views of the National Nuclear Security Administration.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dongare, A.M. Challenges to model the role of heterogeneities on the shock response and spall failure of metallic materials at the mesoscales. J Mater Sci 55, 3157–3166 (2020). https://doi.org/10.1007/s10853-019-04260-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-04260-7