Abstract

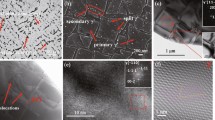

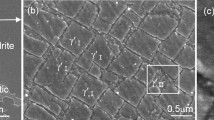

Precipitation and growth behavior of γ′ (Ni3Al) phase are crucial to evaluate the service stability of superalloys. In this work, precipitation and growth mechanisms of γ′ phase in different areas of a newly designed Ni3Al-based superalloy were investigated under short-term thermal exposure conditions. Results showed that twinning γ′ phase and foliated γ′ phase precipitated in eutectic area and interface area, respectively. γ′ phase went through from sphere to precursor plate and plate twinning eventually in eutectic area, which was related to preferred orientation of γ′ phase and local segregation of Al element. Dislocation and sidestep interface between matrix and the precipitation were the main reasons for the formation of twinning γ′ phase. Meanwhile, the morphology of γ′ phases in interface area went through a process from sphere to rod-like, and foliated γ′ phases formed eventually which grew toward eutectic areas with thermal exposure time increasing. Vacancies, distortions caused by different thermal expansion coefficients, lattice mismatch between dual-phase area and eutectic area contributed to the formation and growth of spherical phase. Moreover, reduction in interface energy promoted the transformation of spherical phase to rod-like and foliated γ′ phases. In addition, concentration gradient of Al element and adequate holding time were responsible for the directional growth of foliated γ′ phase.

Similar content being viewed by others

References

Wu YT, Liu YC, Li C et al (2017) Deformation behavior and processing maps of Ni3Al-based superalloy during isothermal hot compression. J Alloys Compd 712:687–695

Sheng LY, Zhang W, Guo JT et al (2009) Microstructure and mechanical properties of Ni3Al fabricated by thermal explosion and hot extrusion. Intermetallics 17:572–577

Singh ARP, Nag S, Hwang JY et al (2011) Influence of cooling rate on the development of multiple generations of γ′ precipitates in a commercial nickel base superalloy. Mater Charact 62:878–886

Srinivasan R, Banerjee R, Hwang JY et al (2009) Atomic scale structure and chemical composition across order-disorder interfaces. Phys Rev Lett 102:86–101

Wang LP, Luo HL, Li SP et al (2007) Effect of heat-treatment on microstructure and stress rupture of MX246A. Foundary 56:395–396

Ges AM, Fornaro O, Palacio HA (2007) Coarsening behavior of a Ni-base superalloy under different heat treatment conditions. Mater Sci Eng, A 458:96–100

James C, Dong M, Matthew F et al (2017) Lattice strain evolution and load partitioning during creep of a Ni-based superalloy single crystal with rafted γ′ microstructure. Scripta Mater 135:77–87

Zrnik J, Strunz P, Vrchovinsky V et al (2004) Degradation of creep properties in a long-term thermally exposed nickel base superalloy. Mater Sci Eng, A 387:728–733

Ges A, Fornaro O, Palacio H (1997) Long term coarsening of γ′ precipitates in a Ni-base superalloy. J Mater Sci 32:3687–3691. https://doi.org/10.1023/A:1018694716756

Li P, Li SS, Han YF (2011) Influence of solution heat treatment on microstructure and stress rupture properties of a NiAl base single crystal superalloy IC6SX. Intermetallics 19:182–186

Zhao K, Ma YH, Lou LH et al (2008) Abnormal precipitation behavior of Ni3Al phase. Mater Sci Eng, A 480:205–208

Ding J, Jiang S, Li Y et al (2018) Microstructure evolution behavior of Ni3Al (γ′) phase in eutectic γ–γ′ of Ni3Al-based alloy. Intermetallics 98:28–33

Westbrook JH (1957) Temperature dependence of the hardness of secondary phases common in turbine bucket alloys. J Met 9:898–904

Sims T, Stoloff S, Magel C (1987) Superalloys. Wiley, New York

Hu ZQ, Liu LR, Jin T et al (2005) The development of Ni-based single crystal superalloy. Aeroengine 31:1–7

Ding J, Jiang S, Wu YT et al (2017) Precipitation and growth behavior of mushroom-like Ni3Al. Mater Lett 211:5–8

Wu YT, Liu YC, Li C et al (2019) Coarsening behavior of γ′ precipitates in the γ′ + γ area of a Ni3Al-based alloy. J Alloys Compd 771:526–533

Lee D, Santella ML, Anderson IM et al (2005) Thermal aging effects on the microstructure and short-term oxidation behavior of a cast Ni3Al alloy. Intermetallics 13:187–196

Bremer FJ, Beyss M, Karthaus E et al (1988) Experimental analysis of the Ni–Al phase diagram. J Cryst Growth 87:185–192

Wang LP, Luo HL, Li SP et al (2007) Effect of heat-treatment on microstructure and stress rupture of MX246A. China Foundry 56:395–399

Wang JT, Han W, Luo HL et al (2014) Hot deformation behavior of Ni3Al-based alloy MX246A. J Iron Steel Res Int 21:264–268

Wu J, Liu YC, Li C et al (2017) Microstructural characterization and phase separation sequences during Solidification of Ni3Al-based superalloy. Acta Metall Sin (Engl Lett) 30:949–956

Yao ZH, Dong JX, Xu C et al (2013) Gamma prime phase evolution during long-time exposure for GH738 superalloy. Trans Mater Heat Treat 34:31–37

Liu JT, Liu GQ, Hu BF et al (2006) The behavior of coarsening in high temperature in FGH96 alloy. Rare Met Mater Eng 35:418–422

Kaufman MJ, Voorhees PW, Johnson WC et al (1989) An elastically induced morphological instability of a misfitting precipitate. Metall Mater Trans A 20:2171–2175

Horton D, Thomson CB, Randle V (1995) Aspects of twinning and grain growth in high purity and commercially pure nickel. Mater Sci Eng, A 203:408–414

Cui ZX, Liu BX (2004) Metallography and heat treatment. Harbin Institute of the Technology Press, Harbin, pp 227–228

Pande CS, Imam MA, Rath BB (1990) Study of annealing twins in fcc metals and alloys. Metall Mater Trans A 21:2891–2896

Rath BB, Imam MA, Pande CS (2000) Nucleation and growth of twin interfaces in fcc metals and alloys. Mater Phys Mech 1:61–66

Mahajan S, Pande CS, Imam MA et al (1997) Formation of annealing twins in fcc crystals. Acta Mater 45:2633–2638

Gleiter H (1969) The mechanism of grain boundary migration. Acta Mater 17:565–573

Knowles DM, Chen QZ (2003) Superlattice stacking fault formation and twinning during creep in γ/γ′ single crystal superalloy CMSX-4. Mater Sci Eng, A 340:88–102

Dash S, Brown N (1963) An investigation of the origin and growth of annealing twins. Acta Mater 11:1067–1075

Randle V (2013) Grain boundary engineering: an overview after 25 years. Met Sci J 26:253–261

Yeom SJ, Yoon DY, Henry MF (1993) The morphological changes of γ′ precipitates in a Ni–8Al (wt pct) alloy during their coarsening. Metall Trans A 24:1975–1981

Barba D, Alabort E, Pedrazzini S et al (2017) On the Microtwining, mechanism in a single crystal superalloy. Scr Mater 135:314–329

Kear B, Oblak J (1974) Deformation models γ′ precipitation hardened Ni-base superalloy. Le Journal de Physique Colloques 35:35–45

Arrell DJ, Vallés JL (1994) Interfacial dislocation based criterion for the prediction of rafting behavior in superalloys. Scr Metall Mater 30:149–153

Tian SG, Zhou HH (1998) The creep-damage behavior of a single crystal ni-based superalloy. Acta Metall Sin 34:57–62

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Granted Nos. 51501053, U1660201 and 51774212) and Provincial Cooperation Fund of Hebei Province for grant and financial support.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xia, X., Peng, Y., Zhang, J. et al. Precipitation and growth behavior of γ′ phase in Ni3Al-based superalloy under thermal exposure. J Mater Sci 54, 13368–13377 (2019). https://doi.org/10.1007/s10853-019-03821-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-03821-0