Abstract

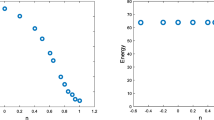

The mechanical responses of two novel kinds of two-dimensional (2D) mechanical metamaterials containing opposite or parallel snapping curved (U-shaped) segments with elastic snap-through instability mechanism are systematically investigated. Under uniaxial loading, the metamaterials undergo a large deformation caused by stiffness mismatch between snapping (buckling instabilities) and supporting (relative stiffer/thicker) components, exhibiting very small transverse deformation after every snapping. Based on the multi-stable mechanism, phase transformation/shape-reconfiguration and zero Poisson’s ratio are achieved up to large morphological change. Nonlinear mechanical responses including self-recovering snapping and multi-stability enabling snapping behaviors can be generated by tuning the geometric parameters (the relative thickness of the snapping and supporting segments as well as the amplitude of the snapping curved segments). Then topology analysis is carried out to develop the 2D structures to a series of 3D hierarchical configurations from which can be chosen for various engineering conditions with enhanced snapping mechanism. Specifically, multi-stable/shape-reconfigurable tubes and cylinders are designed using the 3D configurations. Besides, one of the 3D metamaterials is developed for functional applications as shock absorber and damper, i.e., the process from fully stretched state to fully compacted state is used to absorb energy and reduce incoming pressure with small stiffness and strength; then the fully compacted metamaterials are used to carry load and attenuate vibration with relative bigger stiffness and strength. This work gives advance to the design, analysis and manufacture of functionally reconfigurable mechanical metamaterials.

Similar content being viewed by others

References

Pendry JB, Schurig D, Smith DR (2006) Controlling electromagnetic fields. Science 312:1780–1782

Schurig D, Mock JJ, Justice BJ, Cummer SA, Pendry JB, Starr AF, Smith DR (2006) Metamaterial electromagnetic cloak at microwave frequencies. Science 314:977–980

Wegener M (2013) Metamaterials beyond optics. Science 342:939–940

Maldovan M (2013) Sound and heat revolutions in phononics. Nature 503:209–217

Bückmann T, Thiel M, Kadic M, Schittny R, Wegener M (2014) An elasto-mechanical unfeelability cloak made of pentamode metamaterials. Nat Commun 5:1–6

Xu C, Stiubianu GT, Gorodetsky AA (2018) Adaptive infrared-reflecting systems inspired by cephalopods. Science 359:1495–1500

Wang Q, Jackson JA, Ge Q, Hopkins JB, Spadaccini CM, Fang NX (2016) Lightweight mechanical metamaterials with tunable negative thermal expansion. Phys Rev Lett 117:175901

Boatti E, Vasios N, Bertoldi K (2017) Origami metamaterials for tunable thermal expansion. Adv Mater 29:1700360

Xu H, Farag A, Pasini D (2018) Routes to program thermal expansion in three-dimensional lattice metamaterials built from tetrahedral building blocks. J Mech Phys Solids 117:54–87

Schaedler TA, Jacobsen AJ, Torrents A, Sorensen AE, Lian J, Greer JR, Valdevit L, Carter WB (2011) Ultralight metallic microlattices. Science 334:962–965

Zheng X, Lee H, Weisgraber TH et al (2014) Ultralight, ultrastiff mechanical metamaterials. Science 344:1373–1377

Meza LR, Das S, Greer JR (2014) Strong, lightweight, and recoverable three-dimensional ceramic nanolattices. Science 345:1322–1326

Bauer J, Schroer A, Schwaiger R, Kraft O (2016) Approaching theoretical strength in glassy carbon nanolattices. Nat Mater 15:438–443

Hou X, Silberschmidt VV (2015) Metamaterials with negative Poisson’s ratio: a review of mechanical properties and deformation mechanisms. In: Silberschmidt VV, Matveenko VP (eds) Mechanics of advanced materials. Springer, Cham, pp 155–179

Yu X, Zhou J, Liang H, Jiang Z, Wu L (2018) Mechanical metamaterials associated with stiffness, rigidity and compressibility: a brief review. Prog Mater Sci 94:114–173

Rafsanjani A, Akbarzadeh A, Pasini D (2015) Snapping mechanical metamaterials under tension. Adv Mater 27:5931–5935

Frenzel T, Findeisen C, Kadic M, Gumbsch P, Wegener M (2016) Tailored buckling microlattices as reusable light-weight shock absorbers. Adv Mater 28:5865–5870

Ha CS, Lakes RS, Plesha ME (2018) Design, fabrication, and analysis of lattice exhibiting energy absorption via snap-through behavior. Mater Design 141:426–437

Shan S, Kang SH, Raney JR, Wang P, Fang L, Candido F, Lewis JA, Bertoldi K (2015) Multistable architected materials for trapping elastic strain energy. Adv Mater 27:4296–4301

Restrepo D, Mankame ND, Zavattieri PD (2015) Phase transforming cellular materials. Extreme Mech Lett 4:52–60

Haghpanah B, Salari-Sharif L, Pourrajab P, Hopkins J, Valdevit L (2016) Multistable shape-reconfigurable architected materials. Adv Mater 28:7915–7920

Yang H, Ma L (2018) Multi-stable mechanical metamaterials with shape-reconfiguration and zero Poisson’s ratio. Mater Design 152:181–190

Che K, Yuan C, Wu J, Qi HJ, Meaud J (2017) Three-dimensional-printed multistable mechanical metamaterials with a deterministic deformation sequence. J Appl Mech 84:011004

Lakes RS, Lee T, Bersie A, Wang YC (2001) Extreme damping in composite materials with negative-stiffness inclusions. Nature 410:565–567

Barbarino S, Flores ES, Ajaj RM, Dayyani I, Friswell MI (2014) A review on shape memory alloys with applications to morphing aircraft. Smart Mater Struct 23:063001

Felton SM, Tolley MT, Shin B, Onal CD, Demaine ED, Rus D, Wood RJ (2013) Self-folding with shape memory composites. Soft Matter 9:7688–7694

Rafsanjani A, Pasini D (2016) Bistable auxetic mechanical metamaterials inspired by ancient geometric motifs. Extreme Mech Lett 9:291–296

Hewage TA, Alderson KL, Alderson A, Scarpa F (2016) Double-negative mechanical metamaterials displaying simultaneous negative stiffness and negative Poisson’s ratio properties. Adv Mater 28:10323–10332

Overvelde JTB, Weaver JC, Hoberman C, Bertoldi K (2017) Rational design of reconfigurable prismatic architected materials. Nature 541:347–352

Bauer J, Hengsbach S, Tesari I, Schwaiger R, Kraft O (2014) High-strength cellular ceramic composites with 3D microarchitecture. PNAS 111:2453–2458

Holmes DP, Crosby AJ (2007) Snapping surfaces. Adv Mater 19:3589–3593

Guo Q, Zheng H, Chen Z (2014) Modeling bistable behaviors in morphing structures through finite element simulations. Bio-Med Mater Eng 24:557–562

Silverberg JL, Na J, Evans AA et al (2015) Corrigendum: origami structures with a critical transition to bistability arising from hidden degrees of freedom. Nat Mater 14:389–393

Florijn B, Coulais C, Hecke MV (2014) Programmable mechanical metamaterials. Phys Rev Lett 113:175503

Silverberg JL, Evans AA, McLeod L, Hayward RC, Hull T, Santangelo CD, Cohen I (2014) Applied origami. Using origami design principles to fold reprogrammable mechanical metamaterials. Science 345:647–649

Fu H, Nan K, Bai W et al (2018) Morphable 3D mesostructures and microelectronic devices by multistable buckling mechanics. Nat Mater 17:268–276

Milton GW (2013) Complete characterization of the macroscopic deformations of periodic unimode metamaterials of rigid bars and pivots. J Mech Phys Solids 61:1543–1560

Moore B, Jaglinski T, Stone DS, Lakes RS (2006) Negative incremental bulk modulus in foams. Philos Mag Lett 86:651–659

Puglisi G, Truskinovsky L (2000) Mechanics of a discrete chain with bi-stable elements. J Mech Phys Solids 48:1–27

Jaglinski T, Frascone P, Moore B, Stone DS, Lakes RS (2006) Internal friction due to negative stiffness in the indium-thallium martensitic phase transformation. Phil Mag 86:4285–4303

Qiu J, Lang JH, Slocum AH (2004) A curved-beam bistable mechanism. J Microelectromech Syst 13:137–146

Findeisen C, Hohe J, Kadic M, Gumbsch P (2017) Characteristics of mechanical metamaterials based on buckling elements. J Mech Phys Solids 102:151–164

Yi J, Boyce MC, Lee GF, Balizer E (2006) Large deformation rate-dependent stress–strain behavior of polyurea and polyurethanes. Polymer 47:319–329

Bertoldi K, Boyce MC (2008) Mechanically triggered transformations of phononic band gaps in periodic elastomeric structures. Phys Rev B 77:052105

Yu K, Fang NX, Huang G, Wang Q (2018) Magnetoactive acoustic metamaterials. Adv Mater 30:1706348

Banerjee A, Bernoulli D, Zhang H et al (2018) Ultralarge elastic deformation of nanoscale diamond. Science 360:300–302

Acknowledgements

The present work is supported by National Natural Science Foundation of China under Grant No. 11672085.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, H., Ma, L. Multi-stable mechanical metamaterials by elastic buckling instability. J Mater Sci 54, 3509–3526 (2019). https://doi.org/10.1007/s10853-018-3065-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-3065-y