Abstract

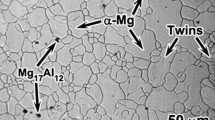

In this research, we performed an experimental investigation into the influence of dynamic strain aging (DSA) and precipitation behavior on the plastic deformation and microstructure evolution in alloy 253MA considering its service temperature. The serrated flow behavior, stress anomaly behavior and negative strain rate sensitivity are considered as the manifestation of DSA within a certain temperature range (TDSA), which can be classified as low (550–700 °C), intermediate (600–750 °C) and high temperatures (700–790 °C) at 0.001 s−1, 0.01 s−1 and 0.1 s−1, respectively. The activation energy of DSA was determined to be 242 kJ/mol, indicating that the diffusion of substitutional solutes, such as Cr and Ni, is mainly responsible for the DSA phenomenon. The characteristic of dislocation substructures is prone to change from linear structure to cellularization structure with a rising deformation temperature in the DSA regime. The stress anomaly behavior can be attributed to the rapid dissolution of σ phase. The initiation of dynamic recrystallization should contribute to the disappearance of DSA by suppressing the dynamical solute atom–dislocation interaction.

Similar content being viewed by others

References

Sawada K, Kushima H, Tabuchi M et al (2011) Microstructural degradation of Gr.91 steel during creep under low stress. Mater Sci Eng A 528:5511–5518

Lee KH, Hong SM, Shim JH et al (2015) Effect of Nb addition on Z-phase formation and creep strength in high-Cr martensitic heat-resistant steels. Mater Charact 102:79–84

Sandvik (2013) Sandvik 253MA (Tube and pipe, seamless)

Fontaine AL, Yen HW, Felfer PJ et al (2015) Atom probe study of chromium oxide spinels formed during intergranular corrosion. Scr Mater 99:1–4

Pan J, Leygraf C, Otsuka T et al (1998) EIS study of high-temperature oxide films on a stainless steel (253MA)-influence of alloying elements. Mater Sci Forum 289–292:1181–1192

Roy M, Pauschitz A, Wernisch J et al (2015) Effect of mating surface on the high temperature wear of 253MA alloy. Mater Corros 55:259–273

Maode Y, Sandstrom R (1988) Influence of cerium on the creep properties of the austenitic stainless steel 253MA. High Temp Technol 6:153–157

Zhang JQ, Di HS, Wang XY (2016) Flow softening of 253MA austenitic stainless steel during hot compression at higher strain rates. Mater Sci Eng A 650:483–491

Atlas Steels (2008) Grade Data Sheet (253MA UNS S30815)

Rolled Alloys (2012) RA 253 MA® Data Sheet

Sleeswyk AW (1958) Slow strain-hardening of ingot iron. Acta Metall 6:598–603

Mulford RA, Kocks UF (1979) New observations on the mechanisms of dynamic strain aging and of jerky flow. Acta Metall 27:1125–1134

Van Den Beukel A (1975) Theory of the effect of dynamic strain aging on mechanical properties. Phys Stat Sol (a) 30:197–206

Hong SG, Lee SB (2005) Mechanism of dynamic strain aging and characterization of its effect on the low-cycle fatigue behavior in type 316L stainless steel. J Nucl Mater 340:307–314

Meng LJ, Sun J, Xing H et al (2009) Serrated flow behavior in AL6XN austenitic stainless steel. J Nucl Mater 394:34–38

Deng ZQ, Liu JH, Yan BJ et al (2018) Monotonous deformation behavior of ferritic FeCrAl alloy in the dynamic strain aging regime. J Alloys Compd 749:664–671

Zhou HW, Fang JF, Chen Y et al (2016) Internal friction studies on dynamic strain aging in P91 ferritic steel. Mater Sci Eng A 676:361–365

Cao Y, Zhang CH, Zhang C et al (2018) Influence of dynamic strain aging on the mechanical properties and microstructural evolution for Alloy 800H during hot deformation. Mater Sci Eng A 724:37–44

Tabatabaei N, Karimi Taheri A, Vaseghi M (2010) Dynamic strain aging of a commercial Al-Mg-Si-Cu alloy during equal channel angular extrusion process. J Alloys Compd 502:59–62

Wang T, Jonas JJ, Qin H et al (2015) Effect of dynamic strain aging on the deformation and twinning behavior of a Mg–2Zn–2Nd alloy. Mater Sci Eng A 645:126–135

Aboulfadl H, Deges J, Choi P et al (2015) Dynamic strain aging studied at the atomic scale. Acta Mater 86:34–42

Brofman PJ, Ansell GS (1978) On the effect of carbon on the stacking fault energy of austenitic stainless steel. Metall Trans A 9:879–880

Rahman MdS, Priyadarshan G, Raja KS et al (2009) Characterization of high temperature deformation behavior of INCONEL 617. Mech Mater 41:261–270

Cao Y, Di HS, Zhang JQ et al (2013) An electron backscattered diffraction study on the dynamic recrystallization behavior of a nickel-chromium alloy (800H) during hot deformation. Mater Sci Eng A 585:71–85

Rodriguez P (1984) Serrated plastic flow. Bull Mater Sci 6:653–663

Fu JX, Cao CM, Tong W et al (2017) The tensile properties and serrated flow behavior of a thermomechanically treated CoCrFeNiMn high-entropy alloy. Mater Sci Eng A 690:418–426

Roy AK, Pal J, Mukhopadhyay C (2008) Dynamic strain ageing of an austenitic superalloy-Temperature and strain rate effects. Mater Sci Eng A 474:363–370

Venkadesan S, Phaniraj C, Sivaprasad PV et al (1992) Activation energy for serrated flow in a 15Cr-15Ni Ti-modified austenitic stainless steel. Acta Metall Mater 40:569–580

Gopinath K, Gogia AK, Kamat SV et al (2009) Dynamic strain ageing in Ni-base superalloy 720Li. Acta Mater 57:1243–1253

Samuel KG, Ray SK, Sasikala G (2006) Dynamic strain ageing in prior cold worked 15Cr-15Ni titanium modified stainless steel (Alloy D9). J Nucl Mater 355:30–37

Hayes RW (1983) On a proposed theory for the disappearance of serrated flow in F.C.C. Ni alloys. Acta Metall 31:365–371

Balluffi RW (1970) On measurements of self-diffusion rates along dislocations in FCC Metals. Phys Stat Sol 42:11–34

Karlsen W, Ivanchenko M, Ehrnsten U et al (2009) Microstructural manifestation of dynamic strain aging in AISI 316 stainless steel. J Nucl Mater 395:156–161

Pham MS, Holdsworth SR (2012) Dynamic strain ageing of AISI 316L during cyclic loading at 300°C: mechanism, evolution, and its effects. Mater Sci Eng A 556:122–133

Momeni A, Dehghani K, Keshmiri H et al (2010) Hot deformation behavior and microstructural evolution of a superaustenitic stainless steel. Mater Sci Eng A 527:1605–1611

Pu EX, Zheng WJ, Song ZG et al (2017) Effects of temperature and strain rate on tensile deformation behavior of superalloy UNS N10276. Mater Sci Eng A 699:88–98

Hrutkay K, Kaoumi D (2014) Tensile deformation behavior of a nickel based superalloy at different temperatures. Mater Sci Eng A 599:196–203

Humphreys FJ, Hatherly M (2004) Recrystallization and related annealing phenomena, 2nd edn. Elsevier, Kidlington, pp 416–450

Sakai T, Belyakov A, Kaibyshev R et al (2014) Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog Mater Sci 60:130–207

Jiang H, Dong JX, Zhang MC et al (2018) Phenomenological model for the effect of strain rate on recrystallization and grain growth kinetics in the 617B alloy. J Alloys Compd 735:1520–1535

Akhiani H, Nezakat M, Szpunar JA (2014) Evolution of deformation and annealing textures in Incoloy 800H/HT via different rolling paths and strains. Mater Sci Eng A 614:250–263

Acknowledgements

This work was financially supported by National Natural Science Foundation of China (No. 51701028), Open Research Fund from the State Key Laboratory of Rolling and Automation (No. 2017RALKFKT005) and Fundamental Research Funds for Central Universities (No. 2018CDXYCL0018).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cao, Y., Zhang, C., Zhang, C. et al. Effect of dynamic strain aging and precipitation on the hot deformation behavior of 253MA heat-resistant alloy. J Mater Sci 54, 1716–1727 (2019). https://doi.org/10.1007/s10853-018-2891-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2891-2