Abstract

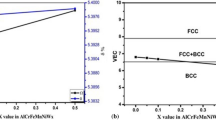

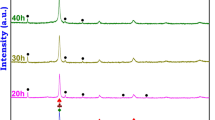

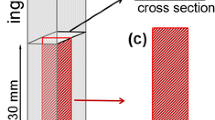

The advancement of nanotechnology demands large-scale preparation of nanocrystalline powder of innovative materials. High-entropy alloys (HEAs) exhibit unique properties: mechanical, thermal, magnetic etc., making them potentials candidates for applications in energy, environment and biomaterials etc. Thus, there is a need to develop novel synthesis methods to prepare nanocrystalline high-purity HEAs in large quantity. Conventional mechanical alloying of the multicomponent metallic powder mixture requires larger milling time and it is prone to contaminations and phase transformation. The present investigation reports a unique approach, involving casting followed by cryomilling, leading to formation of nanocrystalline HEAs powder, which are relatively contaminations free with narrow size distribution. Using examples of two FCC and one BCC single-phase HEAs, it has been shown that large-scale nanocrystalline HEAs powder can be prepared after few hours of cryomilling at 123 K. The formation of nanocrystalline HEAs during cryomilling has been discussed using theoretically available approaches.

Similar content being viewed by others

References

Sattler KD (2010) Handbook of nanophysics: nanotubes and nanowires. CRC Press, Boca Raton, pp 1–10

Liu X, Sui Y, Yang X, Wei Y, Zou B (2016) Cu nanowires with clean surfaces: synthesis and enhanced electrocatalytic activity. ACS Appl Mater Interfaces 8(40):26886–26894

Xu Y, Lin X (2007) Facile fabrication and electrocatalytic activity of Pt0.9Pd0.1 alloy film catalysts. J Power Sources 170(1):13–19

Huang X, El-Sayed MA (2010) Gold nanoparticles: optical properties and implementations in cancer diagnosis and photothermal therapy. J Adv Res 1(1):13–28

Li XD, Chen TP, Liu Y, Leong KC (2014) Influence of localized surface plasmon resonance and free electrons on the optical properties of ultrathin Au films: a study of the aggregation effect. Opt Express 22(5):5124–5132

Tsai T-T, Huang T-H, Chang C-J, Yi-Ju Ho N, Tseng Y-T, Chen C-F (2017) Antibacterial cellulose paper made with silver-coated gold nanoparticles. Sci Rep 7(1):3155-1–3155-10

Cloutier M, Mantovani D, Rosei F (2015) Antibacterial coatings: challenges, perspectives, and opportunities. Trends Biotechnol 33(11):637–652

Yang H-W, Chung C-M, Ding JY (2007) Effect of Ni doping on the structural and magnetic properties of FePt nanoparticles. J Magn Magn Mater 312(1):239–244

Travan A, Marsich E, Donati I, Paoletti S (2007) Silver nanocomposites and their biomedical applications. In: Nanotechnologies for the life sciences, pp 81–127

Patskovsky S, Bergeron E, Rioux D, Simard M, Meunier M (2014) Hyperspectral reflected light microscopy of plasmonic Au/Ag alloy nanoparticles incubated as multiplex chromatic biomarkers with cancer cells. Analyst 139(20):5247–5253

Jiang H, Moon KS, Wong CP (2008) Tin/silver/copper alloy nanoparticle pastes for low temperature lead-free interconnect applications. In: Proceedings—electronic components and technology conference, pp 1400–1404

Naoe M, Matsumiya H, Ichihara T, Nakagawa S (1998) Preparation of soft magnetic films of nanocrystalline Fe–Cu–Nb–Si–B alloy by facing targets sputtering. J Appl Phys 83(11):6673–6675

Cantor B (2014) Multicomponent and high entropy alloys. Entropy 16(9):4749–4768

Samal S, Mohanty S, Mishra AK, Biswas K, Govind B (2014) Mechanical properties of novel Ti–Cu–Ni–Co–Fe high entropy alloys. Mater Sci Forum 790–791:503–508

Mohanty S, Samal S, Tazuddin A, Twari C, Gurao N, Biswas K (2015) Effect of processing route on phase stability in equiatomic multicomponent Ti20Fe20Ni20Co20Cu20 high entropy alloy. Mater Sci Technol 31:1214–1222

Mohanty S, Gurao NP, Biswas K (2014) Sinter ageing of equiatomic Al20Co20Cu20Zn20Ni20 high entropy alloy via mechanical alloying. Mater Sci Eng A 617:211–218

Yeh JW (2006) Recent progress in high-entropy alloys. Ann Chim - Sci Mat 31(6):633–648

Tsai KY, Tsai MH, Yeh JW (2013) Sluggish diffusion in Co–Cr–Fe–Mn–Ni high-entropy alloys. Acta Mater 61(13):4887–4897

Mishra A, Samal S, Biswas K (2012) Solidification behaviour of Ti–Cu–Fe–Co–Ni high entropy alloys. Trans Indian Inst Met 65(6):725–730

Murty BS, Yeh JW, Ranganathan S (2014) High-entropy alloys: basic concepts. In: High entropy alloys. Butterworth-Heinemann, Boston, pp 13–35

Zhou Y, Zhou D, Jin X, Zhang L, Du X, Li B (2018) Design of non-equiatomic medium-entropy alloys. Sci Rep 8(1):1236-1–1236-9

Murty BS, Yeh JW, Ranganathan S (2014) A brief history of alloys and the birth of high-entropy alloys. In: High entropy alloys. Butterworth-Heinemann, Boston, pp 1–12

Miracle DB, Senkov ON (2017) A critical review of high entropy alloys and related concepts. Acta Mater 122(Supplement C):448–511

Pickering EJ, Jones NG (2016) High-entropy alloys: a critical assessment of their founding principles and future prospects. Int Mater Rev 61(3):183–202

Gao MC, Yeh JW, Liaw PK, Zhang Y (2016) High-entropy alloys: fundamentals and applications. Springer, Berlin, pp 1–19

Zhang W, Liaw PK, Zhang Y (2018) Science and technology in high-entropy alloys. Sci China Mater 61(1):2–22

Li RX, Liaw PK, Zhang Y (2017) Synthesis of AlxCoCrFeNi high-entropy alloys by high-gravity combustion from oxides. Mater Sci Eng A 707:668–673

Otto F, Dlouhý A, Somsen C, Bei H, Eggeler G, George EP (2013) The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater 61(15):5743–5755

Gludovatz B, Hohenwarter A, Catoor D, Chang EH, George EP, Ritchie RO (2014) A fracture-resistant high-entropy alloy for cryogenic applications. Science 345(6201):1153–1158

Na SM, Yoo JH, Lambert PK, Jones NJ (2018) Room-temperature ferromagnetic transitions and the temperature dependence of magnetic behaviors in FeCoNiCr-based high-entropy alloys. AIP Adv 8(5):056412-1–056412-7

Huo W, Liu X, Tan S, Fang F, Xie Z, Shang J, Jiang J (2018) Ultrahigh hardness and high electrical resistivity in nano-twinned, nanocrystalline high-entropy alloy films. Appl Surf Sci 439:222–225

Praveen S, Kim HS (2018) High-entropy alloys: potential candidates for high-temperature applications—an overview. Adv Eng Mater 20(1):1700645-1–1700645-22

Kumar A, Gupta M (2016) An insight into evolution of light weight high entropy alloys: a review. Metals 6(9):1–19

Ye YF, Wang Q, Lu J, Liu CT, Yang Y (2016) High-entropy alloy: challenges and prospects. Mater Today 19(6):349–362

Zhang Y, Zhang B, Li K, Zhao G-L, Guo SM (2018) Electromagnetic interference shielding effectiveness of high entropy AlCoCrFeNi alloy powder laden composites. J Alloys Compd 734:220–228

Yadav S, Kumar A, Biswas K (2017) Wear behavior of high entropy alloys containing soft dispersoids (Pb, Bi). Mater Chem Phys 210:222–232

Vaidya M, Prasad A, Parakh A, Murty BS (2017) Influence of sequence of elemental addition on phase evolution in nanocrystalline AlCoCrFeNi: novel approach to alloy synthesis using mechanical alloying. Mater Des 126:37–46

Biswas K, Phanikumar G, Chattopadhyay K, Volkmann T, Funke O, Holland-Moritz D, Herlach DM (2004) Rapid solidification behaviour of undercooled levitated Fe–Ge alloy droplets. Mater Sci Eng A 375-377(Supplement C):464–467

Biswas K, Phanikumar G, Holland-Moritz D, Herlach DM, Chattopadhyay K (2007) Disorder trapping and grain refinement during solidification of undercooled Fe–18 at.% Ge melts. Philos Mag 87(25):3817–3837

Fecht HJ (1995) Nanostructure formation by mechanical attrition. Nanostruct Mater 6(1–4):33–42

Verma A, Biswas K, Tiwary C, Mondal A, Chattopadhyay K (2011) Combined cryo and room-temperature ball milling to produce ultrafine halide crystallites. Metall Mater Trans A 42(4):1127–1137

Tiwary C, Verma A, Kashyp S, Biswas K, Chattopadhyay K (2013) Preparation of freestanding Zn nanocrystallites by combined milling at cryogenic and room temperatures. Metall Mater Trans A 44(4):1917–1924

Tiwary CS, Verma A, Biswas K, Mondal AK, Chattopadhyay K (2011) Preparation of ultrafine CsCl crystallites by combined cryogenic and room temperature ball milling. Ceram Int 37(8):3677–3686

Barai K, Tiwary CS, Chattopadhyay PP, Chattopadhyay K (2012) Synthesis of free standing nanocrystalline Cu by ball milling at cryogenic temperature. Mater Sci Eng A 558:52–58

Tiwary CS, Kashyap S, Biswas K, Chattopadhyay K (2013) Synthesis of pure iron magnetic nanoparticles in large quantity. J Phys D Appl Phys 46(38):385001–385005

Murty BS, Yeh JW, Ranganathan S (2014) Applications and future directions. In: High entropy alloys. Butterworth-Heinemann, Boston, pp 159–169

Kumar N, Biswas K (2015) Fabrication of novel cryomill for synthesis of high purity metallic nanoparticles. Rev Sci Instrum 86(8):083903–083908

Cantor B, Chang ITH, Knight P, Vincent AJB (2004) Microstructural development in equiatomic multicomponent alloys. Mater Sci Eng A 375-377(1-2 SPEC. ISS.):213–218

Williamson GK, Hall WH (1953) X-ray line broadening from filed aluminium and wolfram. Acta Metall 1(1):22–31

Langford JI, Wilson AJC (1978) Scherrer after sixty years: a survey and some new results in the determination of crystallite size. J Appl Crystallogr 11(2):102–113

Shpacovitch V (2012) Application of surface plasmon resonance (SPR) for the detection of single viruses and single biological nano-objects. J Bacteriol Parasitol 3(7):1–3

Messina GC, Sinatra MG, Bonanni V, Brescia R, Alabastri A, Pineider F, Campo G, Sangregorio C, Li-Destri G, Sfuncia G, Marletta G, Condorelli M, Proietti Zaccaria R, De Angelis F, Compagnini G (2016) Tuning the composition of alloy nanoparticles through laser mixing: the role of surface plasmon resonance. J Phys Chem C 120(23):12810–12818

Linic S, Aslam U, Boerigter C, Morabito M (2015) Photochemical transformations on plasmonic metal nanoparticles. Nat Mater 14(6):567–576

Rak MJ, Friscic T, Moores A (2016) One-step, solvent-free mechanosynthesis of silver nanoparticle-infused lignin composites for use as highly active multidrug resistant antibacterial filters. RSC Adv 6(63):58365–58370

Bell GM, Levine S (1976) The electrostrictive effect in diffuse charged layers. J Colloid Interface Sci 56(2):218–226

Kumar N, Biswas K, Gupta RK (2016) Green synthesis of Ag nanoparticles in large quantity by cryomilling. RSC Advances 6(112):111380–111388

Goujon C, Goeuriot P, Delcroix P, Le Caër G (2001) Mechanical alloying during cryomilling of a 5000 Al alloy/AlN powder: the effect of contamination. J Alloys Compd 315(1–2):276–283

Blewitt TH, Coltman RR, Redman JK (1957) Low-temperature deformation of copper single crystals. J Appl Phys 28(6):651–660

Wigley DA (1968) Mechanical properties of materials at low temperatures. Cryogenics 8(1):3–12

Hallén H (1985) A theory of dynamic recovery in F.C.C. metals. Mater Sci Eng 72(2):119–123

Sharma P, Biswas K, Mondal AK, Chattopadhyay K (2009) Size effect on the lattice parameter of KCl during mechanical milling. Scr Mater 61(6):600–603

Rhodin TN (1950) Low temperature oxidation of copper. I. Physical mechanism. J Am Chem Soc 72(11):5102–5106

Kumar N, Biswas K (2017) Cryomilling: an environment friendly approach of preparation large quantity ultra refined pure aluminium nanoparticles. J Mater Res Technol (in press). https://doi.org/10.1016/j.jmrt.2017.05.017

Deepika A, Li LH, Glushenkov AM, Hait SK, Hodgson P, Chen Y (2014) High-efficient production of boron nitride nanosheets via an optimized ball milling process for lubrication in oil. Sci Rep 4:7288-1–7288-6

Acknowledgements

The authors wish to thank SERB-DST for their financial support to carry out this work and wish to thank Advanced Center for Materials Science, Indian Institute of Technology Kanpur for utilizing X-ray diffraction facility.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, N., Tiwary, C.S. & Biswas, K. Preparation of nanocrystalline high-entropy alloys via cryomilling of cast ingots. J Mater Sci 53, 13411–13423 (2018). https://doi.org/10.1007/s10853-018-2485-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2485-z