Abstract

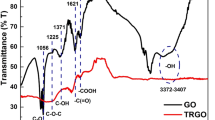

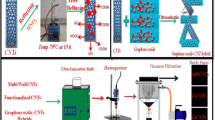

Herein, hybridization of graphene nanosheets and carbon nanotubes (CNTs) has been made to solve the problem of restacking of graphene nanosheets and agglomeration of CNTs. The multiwalled carbon nanotubes (MWCNTs), reduced graphene oxide (RGO) and graphene oxide–carbon nanotubes (GCNTs) reinforced acrylonitrile butadiene styrene (ABS) composites have been prepared using micro-twin-screw extruder. The effect of these reinforcements on static and dynamic mechanical properties of composites is studied. The ultimate tensile strength and elastic modulus for 7 wt.% GCNT–ABS composites show enhancement of 26.1 and 71.3% over pure ABS matrix, respectively. Various parameters such as coefficient “C” factor (the ratio of storage modulus of the composite to polymer in glassy and rubbery regions), degree of entanglement, crosslink density and adhesion factor have been calculated to analyze the interaction between fillers and polymer matrix. The 3-D hybrid structure of GCNTs overcomes the associated problem of CNTs agglomeration and graphene restacking. GCNT hybrid composites show higher dispersion as well as effectiveness for increased filler amount as compared to RGO and MWCNTs based composites. GCNTs prove its superiority over MWCNTs and RGO by showing a synergistic effect in the glass transition temperature and storage modulus. Raman spectroscopy and scanning electron microscopy are used to confirm the interaction and distribution of the filler and matrix, respectively.

Similar content being viewed by others

References

Cheng S, Bocharova V, Belianinov A et al (2016) Unraveling the mechanism of nanoscale mechanical reinforcement in glassy polymer nanocomposites. Nano Lett 16:3630–3637

Reddy PRS, Reddy TS, Srikanth I et al (2016) Effect of viscoelastic behaviour of glass laminates on their energy absorption subjected to high velocity impact. Mater Des 98:272–279

Joseph PV, Mathew G, Joseph K et al (2003) Dynamic mechanical properties of short sisal fibre reinforced polypropylene composites. Compos A Appl Sci Manuf 34:275–290

Hu Y, Wang S, Ling Z, Zhuang Y et al (2003) Preparation and combustion properties of flame retardant nylon 6/montmorillonite nanocomposite. Macromol Mater Eng 288:272–276

Alexandre M, Beyer G, Henrist C, Cloots R, Rulmont A et al (2001) “One-pot” preparation of polymer/clay nanocomposites starting from Na + montmorillonite. 1. Melt intercalation of ethylene-vinyl acetate copolymer. Chem Mater 13:3830–3832

Wang S, Hu Y, Song L, Wang Z et al (2002) Preparation and thermal properties of ABS/montmorillonite nanocomposite. Polym Degrad Stab 77:423–426

Wang S, Hu Y, Lin Z, Gui Z et al (2003) Flammability and thermal stability studies of ABS/montmorillonite nanocomposite. Polym Int 52:1045–1049

Gilman JW, Jackson CL, Morgan AB et al (2000) Flammability properties of polymer-layered-silicate nanocomposites. Polypropylene and polystyrene nanocomposites. Chem Mater 12:1866–1873

Wang S, Hu Y, Wang Z, Yong T et al (2003) Synthesis and characterization of polycarbonate/ABS/montmorillonite nanocomposites. Polym Degrad Stab 80:157–161

Chung D (2003) Structural composite materials tailored for the damping. J Alloy Compd 355:216–223

Sumita M, Shizuma T et al (1983) Effect of reducible properties of temperature, rate of strain, and filler content on the tensile yield stress of nylon 6 composites filled with ultrafine particles. J Macromol Sci Part B Phys 22:601–618

Wildoer JWG et al (1998) Electronic structure of atomically resolved carbon nanotubes. Nature 391(6662):59

Wang Q, Arash B et al (2014) A review on applications of carbon nanotubes and graphenes as nano-resonator sensors. Comput Mater Sci 82:350–360

Coleman JN, Khan U et al (2006) Small but strong: a review of the mechanical properties of carbon nanotube–polymer composites. Carbon 44:1624–1652

B. Arash, Q. Wang, et al (2014) Mechanical properties of carbon nanotube/polymer composites, Scientific reports 4: srep 6479

Debelak B et al (2007) Use of exfoliated graphite filler to enhance polymer physical properties. Carbon 45:1727–1734

Alexandre M, Dubois P (2000) Polymer-layered silicate nanocomposites: preparation, properties and uses of a new class of materials. Mater Sci Eng R Rep 28:1–63

Novoselov KS, Geim AK, Morozov S et al (2004) Electric field effect in atomically thin carbon films. Science 306:666–669

Stoller MD, Park S, Zhu Y et al (2008) Graphene-based ultracapacitors. Nano Lett 8:3498–3502

Lee C, Wei X, Kysar JW et al (2008) Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321:385–388

Balandin AA, Ghosh S, Bao W, Calizo I et al (2008) Superior thermal conductivity of single-layer graphene. Nano Lett 8:902–907

Kim, Keun Soo et al (2009) Large- scale growth of graphene films for stretchable transparent electrodes.” nature 457.7230:706

Bae S, Kim H, Lee Y, Xu X, Park J-S et al (2010) Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat Nanotechnol 5:574–578

Reina A, Jia X, Ho J, Nezich D et al (2008) Large area, few-layer graphene films on arbitrary substrates by chemical vapor deposition. Nano Lett 9:30–35

Stankovich S, Dikin DA, Piner RD, Kohlhaas KA et al (2007) Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 45:1558–1565

Zhang H-B, Wang J-W, Yan Q et al (2011) Vacuum-assisted synthesis of graphene from thermal exfoliation and reduction of graphite oxide. J Mater Chem 21(14):5392–5397

Fernández-Merino M, Guardia L et al (2010) Vitamin C as an innocuous and safe reductant for the preparation of graphene suspensions from graphite oxide. J Phys Chem C 114:6426–6432

Park S et al (2009) Chemical methods for the production of graphenes. Nat Nanotechnol 4:217–224

Shin HJ, Kim KK et al (2009) Efficient reduction of graphite oxide by sodium borohydride and its effect on electrical conductance. Adv Func Mater 19:1987–1992

Qiu Y, Zhang X et al (2011) High performance supercapacitors based on highly conductive nitrogen-doped graphene sheets. Phys Chem Chem Phys 13:12554–12558

Sreekala M, George J et al (2002) The mechanical performance of hybrid phenol-formaldehyde-based composites reinforced with glass and oil palm fibres. Compos Sci Technol 62:339–353

Desai T, Keblinski P et al (2005) Molecular dynamics simulations of polymer transport in nanocomposites. J Chem Phys 122:134910

Bansal Amitabh et al (2005) Quantitative equivalence between polymer nanocomposites and thin polymer films. Nat Mater 4(9):693–698

Menard KP (2008) Dynamic mechanical analysis: a practical introduction. CRC Press, Boca Raton

Cassu SN, Felisberti MI (2005) Comportamento dinâmico-mecânico e relaxações em polímeros e blendas poliméricas. Quim Nova 28:255–263

Ornaghi HL, Pistor V et al (2012) Effect of the epoxycyclohexyl polyhedral oligomeric silsesquioxane content on the dynamic fragility of an epoxy resin. J Non-Cryst Solids 358:427–432

Mangal R, Srivastava S et al (2015) Phase stability and dynamics of entangled polymer-nanoparticle composites. Nat Commun 6:7198

Pistor V, Ornaghi FG, Ornaghi HL et al (2012) Dynamic mechanical characterization of epoxy/epoxycyclohexyl–POSS nanocomposites. Mater Sci Eng A 532:339–345

Qazvini NT, Mohammadi N (2005) Dynamic mechanical analysis of segmental relaxation in unsaturated polyester resin networks: effect of styrene content. Polymer 46:9088–9096

Xiang C, Cox PJ, Kukovecz A, Genorio B, Hashim DP, Yan Z et al (2013) Functionalized low defect graphene nanoribbons and polyurethane composite film for improved gas barrier and mechanical performances. ACS Nano 7:10380–10386

Tang L-C, Wan Y-J, Yan D, Pei Y-B, Zhao L et al (2013) The effect of graphene dispersion on the mechanical properties of graphene/epoxy composites. Carbon 60:16–27

Wang X, Gong L-X, Tang L-C, Peng K et al (2015) Temperature dependence of creep and recovery behaviors of polymer composites filled with chemically reduced graphene oxide. Compos A Appl Sci Manuf 69:288–298

Romanzini D, Lavoratti A, Ornaghi HL et al (2013) Influence of fiber content on the mechanical and dynamic mechanical properties of glass/ramie polymer composites. Mater Des 47:9–15

Araby S, Saber N, Ma X, Kawashima N, Kang H et al (2015) Implication of multi-walled carbon nanotubes on polymer/graphene composites. Mater Des 65:690–699

Mathur RB, Chatterjee S et al (2008) Growth of carbon nanotubes on carbon fibre substrates to produce hybrid/phenolic composites with improved mechanical properties. Composites Science and Technology 68:1608–1615

Gupta TK, Singh BP et al (2013) Improved nanoindentation and microwave shielding properties of modified MWCNT reinforced polyurethane composites. J Mater Chem A 1:9138–9149

Singh BP, Choudhary V et al (2015) Solvent free, efficient, industrially viable, fast dispersion process based amine modified MWCNT reinforced epoxy composites of superior mechanical properties. Adv Mater Lett 6:104–113

Marcano DC, Kosynkin DV et al (2010) Improved synthesis of graphene oxide. ACS Nano 4:4806–4814

Gupta TK, Singh BP et al (2015) Superior nano-mechanical properties of reduced graphene oxide reinforced polyurethane composites. RSC Adv 5:16921–16930

Jyoti J, Basu S, Singh BP et al (2015) Superior mechanical and electrical properties of multiwall carbon nanotube reinforced acrylonitrile butadiene styrene high performance composites. Compos B Eng 83:58–65

Ratim S, Ahmad S, Bonnia N et al (2016) Tensile behavior of SiCNP and MWCNTs filled toughened epoxy nanocomposites: a comparative study. Procedia Chem 19:228–233

Song PA, Liu L, Fu S, Yu Y et al (2013) Striking multiple synergies created by combining reduced graphene oxides and carbon nanotubes for polymer nanocomposites. Nanotechnology 24:125704

Jyoti J, Singh BP et al (2016) Dynamic mechanical properties of multiwall carbon nanotube reinforced ABS composites and their correlation with entanglement density, adhesion, reinforcement and C factor. RSC Adv 6:3997–4006

Ponnamma D, Sadasivuni KK et al (2013) Synergistic effect of multi walled carbon nanotubes and reduced graphene oxides in natural rubber for sensing application. Soft Matter 9:10343–10353

Song K, Zhang Y, Meng J et al (2013) Structural polymer-based carbon nanotube composite fibers: understanding the processing–structure–performance relationship. Materials 6:2543–2577

Oommen Z, Groeninckx G et al (2000) Dynamic mechanical and thermal properties of physically compatibilized natural rubber/poly (methyl methacrylate) blends by the addition of natural rubber-graft-poly (methyl methacrylate). J Polym Sci B Polym Phys 38:525–536

Batistakis C, Lyulin AV et al (2012) Slowing down versus acceleration in the dynamics of confined polymer films. Macromolecules 45:7282–7292

Hameed N, Sreekumar P, Francis B et al (2007) Morphology, dynamic mechanical and thermal studies on poly (styrene-co-acrylonitrile) modified epoxy resin/glass fibre composites. Compos A Appl Sci Manuf 38:2422–2432

Acknowledgement

The authors would like to thank Mrs. Shaveta Sharma for their support in carrying mechanical properties and Mr. Jay Tawale for SEM measurement. The studies were carried out under CSIR-Network project (PSC-0109). One of the authors (Jeevan Jyoti) thanks UGC for the NET/JRF fellowship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jyoti, J., Babal, A.S., Sharma, S. et al. Significant improvement in static and dynamic mechanical properties of graphene oxide–carbon nanotube acrylonitrile butadiene styrene hybrid composites. J Mater Sci 53, 2520–2536 (2018). https://doi.org/10.1007/s10853-017-1592-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1592-6