Abstract

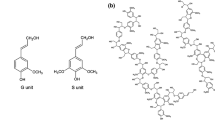

Unique composite nanofibers were produced by electrospinning solvent-fractionated lignin using a small percentage of polyethylene oxide mixed with nanocrystalline cellulose (NCC) for fiber formation and reinforcement, respectively. The materials were characterized and the mechanical properties analyzed as a function of NCC content and thermal exposure (oxidative stabilization and carbonization). At the electrospinning conditions studied, uniform fibers were produced at all NCC concentrations. FTIR analysis of the samples showed shifts in the hydroxyl stretching regions, suggesting intermolecular interactions between the NCC and lignin. After thermal treatment, the mechanical properties of the materials were greatly enhanced for both the lignin and lignin composite fiber mats. The tensile strength and tensile modulus of the mats more than doubled, while the strain at break slightly increased when the materials were exposed to temperatures of 250 °C in an oxidative environment. The tensile strength, tensile modulus and elongation at break values were found to be similar to that of other glassy bioplastics such as polyhydroxybutyrate providing a path to significantly enhance the mechanical properties of technical lignin. NCC loading did not have a significant impact on the performance of the lignin mat for most conditions. Further carbonization of the mats greatly enhanced the stiffness of the mat up to 8 GPa with the inclusion of NCC at the highest loading level. Overall, this work highlights alternative route for the utilization of technical kraft lignin through simple means of heat treatment.

Similar content being viewed by others

References

Marton J (1966) Lignin structure and reactions. Adv I. doi:10.1021/ba-1966-0059

Calvo-Flores FG, Dobado JA (2010) Lignin as renewable raw material. Chemsuschem 3:1227–1235

Katahira R, Mittal A, McKinney K et al (2016) Base-catalyzed depolymerization of biorefinery lignins. ACS Sustain Chem Eng 4:1474–1486

Cui C, Sadeghifar H, Sen S, Argyropoulos DS (2013) Toward thermoplastic lignin polymers; part II: thermal & polymer characteristics of kraft lignin & derivatives. BioResources 8:864–886

Yang S, Zhang Y, Yuan T-Q, Sun R-C (2015) Lignin–phenol–formaldehyde resin adhesives prepared with biorefinery technical lignins. J Appl Polym Sci 132:42493(1–8)

Baker DA, Rials TG (2013) Recent advances in low-cost carbon fiber manufacture from lignin. J Appl Polym Sci 130:713–728

Otani S, Fukuoka Y, Igarashi B, K S (1969) Method for producing carbonized lignin fiber. US Patent 3,461,082

Fukuoka Y (1969) Carbon fiber made for lignin (kayacarbon). Japan Chem Q 63–66

Schreiber M, Vivekanandhan S, Mohanty AK, Misra M (2015) Iodine treatment of lignin–cellulose acetate electrospun fibers: enhancement of green fiber carbonization. ACS Sustain Chem Eng 3:33–41

Hosseinaei O, Harper DP, Bozell JJ, Rials TG (2016) Role of physicochemical structure of organosolv hardwood and herbaceous lignins on carbon fiber performance. ACS Sustain Chem Eng 4:5785–5798

Xia K, Ouyang Q, Chen Y et al (2016) Preparation and characterization of lignosulfonate–acrylonitrile copolymer as a novel carbon fiber precursor. ACS Sustain Chem Eng 4:159–168

Imel AE, Naskar AK, Dadmun MD (2016) Understanding the impact of poly (ethylene oxide) on the assembly of lignin in solution toward improved carbon fiber production. ACS Appl Mater Interfaces 8:3200–3207

Baker FS (2010) Low cost carbon fiber from renewable resources, EERE, US Dept of Energy Project ID# lm_03_baker

Sun Q, Khunsupat R, Akato K et al (2016) A study of poplar organosolv lignin after melt rheology treatment as carbon fiber precursors. Green Chem 18:5015–5024

Braun JL, Holtman KM, Kadla JF (2005) Lignin-based carbon fibers: oxidative thermostabilization of kraft lignin. Carbon N Y 43:385–394

Brodin I, Ernstsson M, Gellerstedt G, Sjöholm E (2012) Oxidative stabilisation of kraft lignin for carbon fibre production. Holzforschung 66:141–147

Zhang W, Sathitsuksanoh N, Simmons B et al (2016) Revealing the thermal sensitivity of lignin during glycerol thermal processing through structural analysis. RSC Adv 6:30234–30246

Baker DA, Gallego NC, Baker FS (2012) On the characterization and spinning of an organic-purified lignin toward the manufacture of low-cost carbon fiber. J Appl Polym Sci 124:227–234

Doshi J, Reneker DH (1995) Electrospinning process and applications of electrospun fibers. J Electrost 35:151–160

Wu J, Wang N, Zhao Y, Jiang L (2013) Electrospinning of multilevel structured functional micro-/nanofibers and their applications. J Mater Chem A 1:7290–7305

Hu S, Zhang S, Pan N, Hsieh Y-L (2014) High energy density supercapacitors from lignin derived submicron activated carbon fibers in aqueous electrolytes. J Power Sources 270:106–112

Lai C, Zhou Z, Zhang L et al (2014) Free-standing and mechanically flexible mats consisting of electrospun carbon nanofibers made from a natural product of alkali lignin as binder-free electrodes for high-performance supercapacitors. J Power Sources 247:134–141

Ago M, Borghei M, Haataja JS, Rojas OJ (2016) Mesoporous carbon soft-templated from lignin nanofiber networks: microphase separation boosts supercapacitance in conductive electrodes. RSC Adv 6:85802–85810

Teng N-Y, Dallmeyer I, Kadla JF (2013) Effect of softwood kraft lignin fractionation on the dispersion of multiwalled carbon nanotubes. Ind Eng Chem Res 52:6311–6317

Dallmeyer I, Lin LT, Li Y et al (2014) Preparation and characterization of interconnected, kraft lignin-based carbon fibrous materials by electrospinning. Macromol Mater Eng 299:540–551

Lin L, Li Y, Ko FK (2013) Fabrication and properties of lignin based carbon nanofiber. J Fiber Bioeng Inform 6:335–347

Hu S, Hsieh Y-L (2013) Ultrafine microporous and mesoporous activated carbon fibers from alkali lignin. J Mater Chem A 1:11279–11288

Duval A, Vilaplana F, Crestini C, Lawoko M (2016) Solvent screening for the fractionation of industrial kraft lignin. Holzforschung 70:11–20

Passoni V, Scarica C, Levi M et al (2016) Fractionation of industrial softwood kraft lignin: solvent selection as a tool for tailored material properties. ACS Sustain Chem Eng 4:2232–2242

Sadeghifar H, Sen S, Patil SV, Argyropoulos DS (2016) Toward carbon fibers from single component kraft lignin systems; optimization of chain extension chemistry. ACS Sustain Chem Eng 4:5230–5237

Qin W, Kadla JF (2011) Effect of organoclay reinforcement on lignin-based carbon fibers. Ind Eng Chem Res 50:12548–12555

Ago M, Okajima K, Jakes JE et al (2012) Lignin-based electrospun nanofibers reinforced with cellulose nanocrystals. Biomacromol 13:918–926

Ago M, Jakes JE, Johansson L-S et al (2012) Interfacial properties of lignin-based electrospun nanofibers and films reinforced with cellulose nanocrystals. ACS Appl Mater Interfaces 4:6849–6856

Ago M, Jakes J, Rojas O (2013) Thermomechanical properties of lignin-based electrospun nanofibers and films reinforced with cellulose nanocrystals: a dynamic mechanical and nanoindentation study. ACS Appl Mater Interfaces 5:11768–11776

Noorani S, Simonsen J, Atre S (2007) Nano-enabled microtechnology: polysulfone nanocomposites incorporating cellulose nanocrystals. Cellulose 14:577–584

Dallmeyer I, Chowdhury S, Kadla JF (2013) Preparation and characterization of kraft lignin-based moisture-responsive films with reversible shape-change capability. Biomacromol 14:2354–2363

Dong XM, Kimura T, Revol J-F, Gray DG (1996) Effects of ionic strength on the isotropic–chiral nematic phase transition of suspensions of cellulose crystallites. Langmuir 12:2076–2082

Dong X, Revol J, Gray D (1998) Effect of microcrystallite preparation conditions on the formation of colloid crystals of cellulose. Cellulose 5:19–32

Dong H, Strawhecker KE, Snyder JF et al (2012) Cellulose nanocrystals as a reinforcing material for electrospun poly (methyl methacrylate) fibers: formation, properties and nanomechanical characterization. Carbohydr Polym 87:2488–2495

Azizi Samir MAS, Alloin F, Sanchez JY et al (2004) Preparation of cellulose whiskers reinforced nanocomposites from an organic medium suspension. Macromolecules 37:1386–1393

Viet D, Beck-Candanedo S, Gray DG (2006) Dispersion of cellulose nanocrystals in polar organic solvents. Cellulose 14:109–113

Elazzouzi-Hafraoui S, Nishiyama Y, Putaux J-L et al (2008) The shape and size distribution of crystalline nanoparticles prepared by acid hydrolysis of native cellulose. Biomacromol 9:57–65

Zhou C, Chu R, Wu R, Wu Q (2011) Electrospun polyethylene oxide/cellulose nanocrystal composite nanofibrous mats with homogeneous and heterogeneous microstructures. Biomacromol 12:2617–2625

Park W-I, Kang M, Kim H-S, Jin H-J (2007) Electrospinning of poly (ethylene oxide) with bacterial cellulose whiskers. Macromol Symp 249–250:289–294

Macossay J, Marruffo A, Rincon R et al (2007) Effect of needle diameter on nanofiber diameter and thermal properties of electrospun poly (methyl methacrylate). Polym Adv Technol 18:180–183

Teng N-Y, Dallmeyer I, Kadla JF (2013) Incorporation of multiwalled carbon nanotubes into electrospun softwood kraft lignin-based fibers. J Wood Chem Technol 33:299–316

Zheng LX, O’Connell MJ, Doorn SK et al (2004) Ultralong single-wall carbon nanotubes. Nat Mater 3:673–676

Zheng L, Sun G, Zhan Z (2010) Tuning array morphology for high-strength carbon-nanotube fibers. Small 6:132–137

Sen S, Patil S, Argyropoulos DS (2015) Thermal properties of lignin in copolymers, blends, and composites: a review. Green Chem 17:4862–4887

Singh S, Mohanty AK, Sugie T et al (2008) Renewable resource based biocomposites from natural fiber and polyhydroxybutyrate-co-valerate (PHBV) bioplastic. Compos Part A Appl Sci Manuf 39:875–886

Favier V, Chanzy H, Cavaille J-YY (1995) Polymer nanocomposites reinforced by cellulose whiskers. Macromolecules 28:6365–6367

Ding R, Wu H, Thunga M et al (2016) Processing and characterization of low-cost electrospun carbon fibers from organosolv lignin/polyacrylonitrile blends. Carbon N Y 100:126–136

Wanasekara ND, Santos RPO, Douch C et al (2016) Orientation of cellulose nanocrystals in electrospun polymer fibres. J Mater Sci 51:218–227. doi:10.1007/s10853-015-9409-y

Acknowledgements

This research was funded by the NSERC LIGNOWORKS Biomaterials and Chemicals Strategic Research Network. Also, FK and SR received support from the Canada Research Chairs program.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Cho, M., Karaaslan, M.A., Renneckar, S. et al. Enhancement of the mechanical properties of electrospun lignin-based nanofibers by heat treatment. J Mater Sci 52, 9602–9614 (2017). https://doi.org/10.1007/s10853-017-1160-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1160-0