Abstract

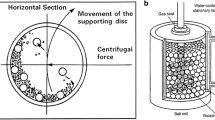

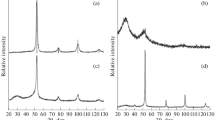

Ball milling (BM) is a well-established technique for producing different materials in powder shape. Dynamical analysis of BM helps to optimize the process through simple but general relations (e.g., definition of an equivalent milling time). Concerning the field of study of magnetocaloric effect (MCE), BM is used in different ways: as a single step process (mechanical alloying), as an initial step to enhance mixing of the elements (e.g., to speed up the formation of the desired intermetallic phase) or as a final step (e.g., hydriding of La–Fe–Si). In this contribution, besides a simple description of the effects of some geometrical parameters on the power released during BM and a short review of the BM contribution to the research field of MCE, we will discuss the effect of the microstructure of the starting material and the granular shape inherent to BM on magnetic materials exhibiting MCE.

Similar content being viewed by others

References

Suryanarayana C (2001) Mechanical alloying and milling. Prog Mater Sci 46:1–184. doi:10.1016/s0079-6425(99)00010-9

Suryanarayana C, Al-Aqeeli N (2013) Mechanically alloyed nanocomposites. Prog Mater Sci 58:383–502. doi:10.1016/j.pmatsci.2012.10.001

Balaz P, Achimovicova M, Balaz M et al (2013) Hallmarks of mechanochemistry: from nanoparticles to technology. Chem Soc Rev 42:7571–7637. doi:10.1039/c3cs35468g

Blázquez JS, Ipus JJ, Lozano-Pérez S, Conde A (2013) Metastable soft magnetic materials produced by mechanical alloying: analysis using an equivalent time approach. JOM 65:870–882. doi:10.1007/s11837-013-0616-1

Ipus JJ, Blázquez JS, Franco V, Conde A, Lozano-Pérez S (2012) Analysis of the magnetic anisotropy in Fe–Co–Nb–B alloys partially amorphized by mechanical alloying. Phys Express 2:8 (1-7)

Ipus JJ, Blázquez JS, Franco V, Conde CF, Conde A (2011) Two milling time regimes in the evolution of magnetic anisotropy of mechanically alloyed soft magnetic powders. J Alloy Compd 509:1407–1410. doi:10.1016/j.jallcom.2010.10.207

Hernando A, Vázquez M, Kulik T, Prados C (1995) Analysis of the dependence of spin-spin correlations on the thermal treatment of nanocrystalline materials. Phys Rev B 51:3581–3586. doi:10.1103/PhysRevB.51.3581

Gschneidner KA, Pecharsky VK (2000) Magnetocaloric materials. Annu Rev Mater Sci 30:387–429. doi:10.1146/annurev.matsci.30.1.387

Franco V, Blázquez JS, Ingale B, Conde A (2012) The magnetocaloric effect and magnetic refrigeration near room temperature: materials and models. Annu Rev Mater Res 42:305–342. doi:10.1146/annurev-matsci-062910-100356

Tishin AM, Spichkin YI, Zverev VI, Egolf PW (2016) A review and new perspectives for the magnetocaloric effect: new materials and local heating and cooling inside the human body. International Journal of Refrigeration-Revue Internationale Du Froid 68:177–186. doi:10.1016/j.ijrefrig.2016.04.020

Ghahremani M, Aslani A, Siddique A, Bennett LH, Della Torre E (2016) Tuning the heat transfer medium and operating conditions in magnetic refrigeration. AIP Adv 6:075221. doi:10.1063/1.4960379

Rodionov ID, Koshkid’ko YS, Cwik J et al (2015) Magnetocaloric effect in Ni50Mn35In15 Heusler alloy in low and high magnetic fields. JETP Lett 101:385–389. doi:10.1134/s0021364015060107

Tocado L, Palacios E, Burriel R (2009) Entropy determinations and magnetocaloric parameters in systems with first-order transitions: study of MnAs. J Appl Phys 105:093918. doi:10.1063/1.3093880

Carvalho AMG, Coelho AA, von Ranke PJ, Alves CS (2011) The isothermal variation of the entropy (ΔST) may be miscalculated from magnetization isotherms in some cases: MnAs and Gd5Ge2Si2 compounds as examples. J Alloy Compd 509:3452–3456. doi:10.1016/j.jallcom.2010.12.088

Franco V (2014) Lake shore cryotronics: application note. http://www.lakeshore.com/products/Vibrating-Sample-Magnetometer/Pages/MCE.aspx

Kaeswurm B, Franco V, Skokov KP, Gutfleisch O (2016) Assessment of the magnetocaloric effect in La, Pr(Fe, Si) under cycling. J Magn Magn Mater 406:259–265. doi:10.1016/j.jmmm.2016.01.045

Blázquez JS, Ipus JJ, Moreno-Ramírez LM, Borrego JM, Lozano-Pérez S, Franco V, Conde CF, Conde A (2015) Analysis of the magnetocaloric effect in powder samples obtained by ball milling. Metall Mater Trans E 2:131–138. doi:10.1007/s40553-015-0050-0

Abdellaoui M, Gaffet E (1995) The physics of mechanical alloying in a planetary ball mill: mathematical treatment. Acta Metall Mater 43:1087–1098. doi:10.1016/0956-7151(95)92625-7

Ipus JJ, Blázquez JS, Franco V, Millán M, Conde A, Oleszak D, Kulik T (2008) An equivalent time approach for scaling the mechanical alloying processes. Intermetallics 16:470–478. doi:10.1016/j.intermet.2007.12.011

Lebrun P, Froyen L, Delaey L (1993) The modelling of the mechanical alloying process in a planetary ball mill: comparison between theory and in situ observations. Mater Sci Eng A-Struct Mater Prop Microstruct Process 161:75–82. doi:10.1016/0921-5093(93)90477-v

Delogu F, Cocco G (2005) Kinetics of structural evolution in immiscible Ag–Cu and Co–Cu systems under mechanical processing conditions. Mater Sci Eng A-Struct Mater Prop Microstruct Process 402:208–214. doi:10.1016/j.msea.2005.04.007

Chevalier B, Bobet JL, Marcos JS, Fernandez JR, Sal JCG (2005) Magnetocaloric properties of amorphous GdNiAl obtained by mechanical grinding. Appl Phys Mater Sci Process 80:601–606. doi:10.1007/s00339-003-2239-9

Zhang TB, Provenzano V, Chen YG, Shull RD (2008) Magnetic properties of a high energy ball-milled amorphous Gd5Si1.8Ge1.8Sn0.4 alloy. Solid State Commun 147:107–110. doi:10.1016/j.ssc.2008.05.009

Shishkin DA, Baranov NV, Gubkin AF, Volegov AS, Gerasimov EG, Terentev PB, Stashkova LA (2014) Impact of amorphization on the magnetic state and magnetocaloric properties of Gd3Ni. Appl Phys Mater Sci Process 116:1403–1407. doi:10.1007/s00339-014-8245-2

Ipus JJ, Blázquez JS, Franco V, Conde A (2008) Mechanical alloying of Fe100 − x−yNbxBy (x = 5, 10; y = 10, 15): from pure powder mixture to amorphous phase. Intermetallics 16:1073–1082. doi:10.1016/j.intermet.2008.06.006

Ipus JJ, Blázquez JS, Franco V, Conde A, Kiss LF (2009) Magnetocaloric response of Fe75Nb10B15Fe75Nb10B15 powders partially amorphized by ball milling. J Appl Phys 105:123922. doi:10.1063/1.3155982

Ipus JJ, Blázquez JS, Franco V, Conde A (2010) Influence of Co addition on the magnetic properties and magnetocaloric effect of Nanoperm (Fe1 − XCoX)75Nb10B15 type alloys prepared by mechanical alloying. J Alloy Compd 496:7–12. doi:10.1016/j.jallcom.2009.12.029

Moreno LM, Blázquez JS, Ipus JJ, Borrego JM, Franco V, Conde A (2014) Magnetocaloric effect of Co62Nb6Zr2B30 amorphous alloys obtained by mechanical alloying or rapid quenching. J Appl Phys 115:17A302. doi:10.1063/1.4857595

Ipus JJ, Ucar H, McHenry ME (2011) Near room temperature magnetocaloric response of an (FeNi)ZrB alloy. IEEE Trans Magn 47:2494–2497. doi:10.1109/tmag.2011.2159781

Ucar H, Craven M, Laughlin DE, McHenry ME (2014) Effect of Mo addition on structure and magnetocaloric effect in γ-FeNi nanocrystals. J Electron Mater 43:137–141. doi:10.1007/s11664-013-2725-6

Chaudhary V, Repaka DVM, Chaturvedi A, Sridhar I, Ramanujan RV (2014) Magnetocaloric properties and critical behavior of high relative cooling power FeNiB nanoparticles. J Appl Phys 116:163918. doi:10.1063/1.4900736

Chaudhary V, Ramanujan RV (2015) Magnetic and structural properties of high relative cooling power (Fe70Ni30)92Mn8 magnetocaloric nanoparticles. J Phys D-Appl Phys 48:305003. doi:10.1088/0022-3727/48/30/305003

Varzaneh AG, Kameli P, Karimzadeh F, Aslibeiki B, Varvaro G, Salamati H (2014) J Alloy Compd 598:6–10. doi:10.1016/j.jallcom.2014.01.249

Gomes AM, das Virgens MG, Continentino MA, Checon JCC, Lopez A, Azevedo IS (2008) Behavior of the inverse magnetocaloric effect in RuSr2Eu1.5Ce0.5Cu2O10 − δ. J Magn Magn Mater 320:E513–E515. doi:10.1016/j.jmmm.2008.02.108

Anwar MS, Ahmed F, Koo BH (2014) Structural distortion effect on the magnetization and magnetocaloric effect in Pr modified La0.65Sr0.35MnO3 manganite. J Alloy Compd 617:893–898. doi:10.1016/j.jallcom.2014.08.105

Zouari S, Ellouze M, Nasri A, Cherif W, Hlil EK, Elhalouani F (2014) Morphology, structural, magnetic, and magnetocaloric properties of Pr0.7Ca0.3MnO3 nanopowder prepared by mechanical ball milling method. J Supercond Novel Magn 27:555–563. doi:10.1007/s10948-013-2306-1

Rayaprol S, Kaushik SD (2015) Magnetic and magnetocaloric properties of FeMnO3. Ceram Int 41:9567–9571. doi:10.1016/j.ceramint.2015.04.017

Messaoui I, Riahi K, Cheikhrouhou-Koubaa W, Koubaa M, Cheikhrouhou A, Hlil EK (2016) Phenomenological model of the magnetocaloric effect on Nd0.7Ca0.15Sr0.15MnO3 compound prepared by ball milling method. Ceram Int 42:6825–6832. doi:10.1016/j.ceramint.2016.01.060

Schouwink P, Didelot E, Lee Y-S, Mazet T, Cerny R (2016) Structural and magnetocaloric properties of novel gadolinium borohydrides. J Alloy Compd 664:378–384. doi:10.1016/j.jallcom.2015.12.182

Ipus JJ, Borrego JM, Blázquez JS, Stoica M, Franco V, Conde A (2015) Influence of hot compaction on microstructure and magnetic properties of mechanically alloyed Fe(Co)-based amorphous compositions. J Alloy Compd 653:546–551. doi:10.1016/j.jallcom.2015.09.074

Zhong W, Liu W, Wu XL, Tang NJ, Chen W, Au CT, Du YW (2004) Magnetocaloric effect in the ordered double perovskite Sr2FeMo1 − xWxO6. Solid State Commun 132:157–162. doi:10.1016/j.ssc.2004.07.060

Zhang P, Yang H, Zhang S, Ge H, Hua S (2013) Magnetic and magnetocaloric properties of perovskite La0.7Sr0.3Mn1 − xCoxO3. Phys B-Condens Matter 410:1–4. doi:10.1016/j.physb.2012.10.022

Zhong W, Wu XL, Tang NJ, Liu W, Chen W, Au CT, Du YW (2004) Magnetocaloric effect in ordered double-perovskite Ba22FeMoO66 synthesized using wet chemistry. Eur Phys J B 41:213–217. doi:10.1140/epjb/e2004-00312-9

Gass J, Srikanth H, Kislov N, Srinivasan SS, Emirov Y (2008) Magnetization and magnetocaloric effect in ball-milled zinc ferrite powder. J Appl Phys 103:07B309. doi:10.1063/1.2829754

Yan A, Muller KH, Schultz L, Gutfleisch O (2006) Magnetic entropy change in melt-spun MnFePGe (invited). J Appl Phys 99:08K903. doi:10.1063/1.2162807

Czaja P, Przewoznik J, Fitta M et al (2016) J Magn Magn Mater 401:223–230. doi:10.1016/j.jmmm.2015.10.043

Songlin Dagula, Tegus O, Bruck E, de Boer FR, Buschow KHJ (2002) Magnetic and magnetocaloric properties of Mn5Ge3 − xSbx. J Alloy Compd 337:269–271. doi:10.1016/S0925-8388(01)01935-1

Brück E, Tegus O, Zhang L, Li XW, de Boer FR, Buschow KHJ (2004) Magnetic refrigeration near room temperature with Fe2P-based compounds. J Alloy Compd 383:32–36. doi:10.1016/j.jallcom.2004.04.042

Brück E, Ilyn M, Tishin AM, Tegus O (2005) Magnetocaloric effects in MnFeP1 − xAsx-based compounds. J Magn Magn Mater 290:8–13. doi:10.1016/j.jmmm.2004.11.152

Dagula W, Tegus O, Fuquan B et al (2005) Magnetic-entropy change in Mn/sub 1.1/Fe/sub 0.9/P/sub 1-x/Ge/sub x/compounds. IEEE Trans Magn 41:2778–2780. doi:10.1109/tmag.2005.854774

Tegus O, Fuquan B, Dagula W, Zhang L, Brück E, Si PZ, de Boer FR, Buschow KHJ (2005) Magnetic-entropy change in Mn1.1Fe0.9P0.7As0.3–xGex. J Alloy Compd 396:6–9. doi:10.1016/j.jallcom.2004.12.001

Dagula W, Tegus O, Li XW, Song L (2006) Magnetic properties and magnetic-entropy change of MnFeP0.5As0.5 − xSix(x = 0–0.3) compounds. J Appl Phys 99:08Q105. doi:10.1063/1.2158969

Lozano JA, Kostow MP, Brück E, de Lima JC, Prata AT, Wendhausen PAP (2008) Porous manganese-based magnetocaloric material for magnetic refrigeration at room temperature. J Magn Magn Mater 320:E189–E192. doi:10.1016/j.jmmm.2008.02.044

Yue M, Li ZQ, Xu H, Huang QZ, Liu XB (2010) Effect of annealing on the structure and magnetic properties of Mn1.1Fe0.9P0.8Ge0.2Mn1.1Fe0.9P0.8Ge0.2 compound. J Appl Phys 107:09A939. doi:10.1063/1.3358620

Liu DM, Yue M, Zhang JX et al (2009) Origin and tuning of the magnetocaloric effect in the magnetic refrigerant Mn1.1Fe0.9(P0.8Ge0.2). Phys Rev B 79:014435. doi:10.1103/PhysRevB.79.014435

Zhang L, Brück E, Tegus O, Buschow KHJ, de Boer FR (2003) The crystallographic phases and magnetic properties of Fe2MnSi1 − xGex. Phys B-Condens Matter 328:295–301. doi:10.1016/s0921-4526(02)01853-7

Brück E, Tegus O, Thanh DTC, Trung NT, Buschow KHJ (2008) A review on Mn based materials for magnetic refrigeration: structure and properties. International Journal of Refrigeration-Revue Internationale Du Froid 31:763–770. doi:10.1016/j.ijrefrig.2007.11.013

Yibole H, Guillou F, Caron L et al (2015) Moment evolution across the ferromagnetic phase transition of giant magnetocaloric (Mn, Fe)2(P, Si, B) compounds. Phys Rev B 91:014429. doi:10.1103/PhysRevB.91.014429

Sun NK, Cui WB, Li D, Geng DY, Yang F, Zhang ZD (2008) Giant room-temperature magnetocaloric effect in Mn1 − xCrxAs. Appl Phys Lett 92:072504. doi:10.1063/1.2884524

Cui WB, Liu W, Zhang Q, Li B, Liu XH, Yang F, Zhao XG, Zhang ZD (2010) Carbon-doping effects on the metamagnetic transition and magnetocaloric effect in MnAsCx. J Magn Magn Mater 322:2223–2226. doi:10.1016/j.jmmm.2010.02.014

Cui WB, Lv XK, Yang F, Yu Y, Skomski R (2010) Interstitial-nitrogen effect on phase transition and magnetocaloric effect in Mn(As, Si) (invited). J Appl Phys 107:09A938. doi:10.1063/1.3358617

Sun NK, Li D, Xu SN, Wang ZH, Zhang ZD (2011) Room-temperature magnetocaloric effect in (Co0.35Mn0.65)2P compound. J Mater Sci Technol 27:382–384. doi:10.1016/S1005-0302(11)60078-9

Ma L, Guillou F, Yibole H et al (2015) Structural, magnetic and magnetocaloric properties of (Mn, Co)2(Si, P) compounds. J Alloy Compd 625:95–100. doi:10.1016/j.jallcom.2014.11.072

de Boer FR, Boom R, Mattens WCM, Miedema AR, Niessen AK (1988) Cohesion in metals. Elsevier Science Pub. B.V., Amsterdam

Passamani EC, Takeuchi AY, Alves AL, Demuner AS, Favre-Nicolin E (2007) Magnetocaloric properties of (La, RE)Fe11.4Si1.6(La, RE)Fe11.4Si1.6 compounds (RE = Y, Gd). J Appl Phys 102:093906. doi:10.1063/1.2803658

Cui WB, Liu W, Liu XH, Guo S, Han Z, Zhao XG, Zhang ZD (2009) Beneficial effect of minor Al substitution on the magnetocaloric effect of Mn1 − xAlxAs. Mater Lett 63:595–597. doi:10.1016/j.matlet.2008.11.056

Phejar M, Paul-Boncour V, Bessais L (2010) Structural and magnetic properties of magnetocaloric LaFe13–xSix compounds synthesized by high energy ball-milling. Intermetallics 18:2301–2307. doi:10.1016/j.intermet.2010.07.022

Phejar M, Paul-Boncour V, Bessais L (2016) Investigation on structural and magnetocaloric properties of LaFe13 − xSix(H, C)y compounds. J Solid State Chem 233:95–102. doi:10.1016/j.jssc.2015.10.016

Guetari R, Bez R, Cizmas CB, Mliki N, Bessais L (2013) Magnetic properties and magneto-caloric effect in pseudo-binary intermetallic (Pr, Dy)2Fe17. J Alloy Compd 579:156–159. doi:10.1016/j.jallcom.2013.04.167

Bulatova R, Bahl C, Andersen K, Kuhn LT, Pryds N (2015) Functionally graded ceramics fabricated with side-by-side tape casting for use in magnetic refrigeration. Int J Appl Ceram Technol 12:891–898. doi:10.1111/ijac.12298

Lanzarini J, Barriere T, Sahli M et al (2015) Thermoplastic filled with magnetocaloric powder. Mater Des 87:1022–1029. doi:10.1016/j.matdes.2015.08.057

Liu DM, Zhang H, Wang SB et al (2015) J Alloy Compd 633:120–126. doi:10.1016/j.jallcom.2015.01.141

Kaeswurm B, Friemert K, Guersoy M, Skokov KP, Gutfleisch O (2016) Direct measurement of the magnetocaloric effect in cementite. J Magn Magn Mater 410:105–108. doi:10.1016/j.jmmm.2016.02.080

Patissier A, Paul-Boncour V (2015) J Alloy Compd 645:143–150. doi:10.1016/j.jallcom.2015.04.199

Bartok A, Kustov M, Cohen LF, Pasko A, Zehani K, Bessais L, Mazaleyrat F, LoBue M (2016) Study of the first paramagnetic to ferromagnetic transition in as prepared samples of Mn–Fe–P–Si magnetocaloric compounds prepared by different synthesis routes. J Magn Magn Mater 400:333–338. doi:10.1016/j.jmmm.2015.08.045

Kupseh A, Levin AA, Meyer DC (2005) Structural phase transition in Tb5(Si0.6Ge0.4)4 at low temperature. Cryst Res Technol 40:42–51. doi:10.1002/crat.200410306

Gao Q, Yu BF, Wang CF, Zhang B, Yang DX, Zhang Y (2006) Experimental investigation on refrigeration performance of a reciprocating active magnetic regenerator of room temperature magnetic refrigeration. International Journal of Refrigeration-Revue Internationale Du Froid 29:1274–1285. doi:10.1016/j.ijrefrig.2005.12.015

Rajkumar DM, Raja MM, Gopalan R, Chandrasekaran V (2008) J Magn Magn Mater 320:1479–1484. doi:10.1016/j.jmmm.2007.12.005

Chrobak A, Bajorek A, Chelkowska G, Haneczok G, Kwiecien M (2009) Magnetic properties and magnetocaloric effect of Gd(Ni1–xFex)3 crystalline compound and powder. Phys Status Solidi A-Appl Mater Sci 206:731–737. doi:10.1002/pssa.200824470

Pires AL, Belo JH, Turcaud J et al (2015) Influence of short time milling in R5(Si, Ge)4, R = Gd and Tb, magnetocaloric materials. Mater Des 85:32–38. doi:10.1016/j.matdes.2015.06.099

Ipus JJ, Blázquez JS, Franco V, Stoica M, Conde A (2014) Milling effects on magnetic properties of melt spun Fe–Nb–B alloy. J Appl Phys 115:17B518. doi:10.1063/1.4866700

Shao Y, Zhang J, Lai JKL, Shek CH (1996) Magnetic entropy in nanocomposite binary gadolinium alloys. J Appl Phys 80:76–80. doi:10.1063/1.362773

Llamazares JLS, Pérez MJ, Álvarez P et al (2009) The effect of ball milling in the microstructure and magnetic properties of Pr2Fe17 compound. J Alloy Compd 483:682–685. doi:10.1016/j.jallcom.2008.07.210

Álvarez P, Gorría P, Franco V, Sánchez-Marcos J, Pérez MJ, Sánchez-Llamazares JL, Puente-Orench I, Blanco JA (2010) Nanocrystalline Nd2Fe17 synthesized by high-energy ball milling: crystal structure, microstructure and magnetic properties. J Phys-Condens Matter 22:216005. doi:10.1088/0953-8984/22/21/216005

Zhang XY, Chen YJ, Lu LY, Li ZY (2006) A potential oxide for magnetic refrigeration application: CrO2 particles. J Phys-Condens Matter 18:L559. doi:10.1088/0953-8984/18/44/l01

Das SD, Mohapatra N, Iyer KK, Bapat RD, Sampathkumaran EV (2009) Magnetic behavior of nanocrystalline ErCo2. J Phys-Condens Matter 21:296004. doi:10.1088/0953-8984/21/29/296004

Phan MH, Morales MB, Chinnasamy CN, Latha B, Harris VG, Srikanth H (2009) Magnetocaloric effect in bulk and nanostructured Gd3Fe5O12 materials. J Phys D-Appl Phys 42:115007. doi:10.1088/0022-3727/42/11/115007

Alves AL, Passamani EC, Nascimento VP, Takeuchi AY, Larica C (2010) Influence of grain refinement and induced crystal defects on the magnetic properties of Ni50Mn36Sn14 Heusler alloy. J Phys D-Appl Phys 43:345001. doi:10.1088/0022-3727/43/34/345001

Das R, Perumal A, Srinivasan A (2013) Effect of particle size on the magneto-caloric properties of Ni51Mn34In14Si1 alloy. J Alloy Compd 572:192–198. doi:10.1016/j.jallcom.2013.03.235

do Couto GG, Svitlyk V, Jafelicci M, Mozharivskyj Y (2011) Bulk and high-energy ball-milled Gd5Si2Ge2: comparative study of magnetic and magnetocaloric properties. Solid State Sci 13:209–215. doi:10.1016/j.solidstatesciences.2010.11.016

Couillaud S, Chevalier B, Paul-Boncour V, Bobet JL (2012) On the magnetic properties of pseudo-Laves phases RE1 − yYyNi4 − xAlxMg with RE = La, Ce and Gd prepared by both melting and ball milling. J Alloys Compd 525:166–171. doi:10.1016/j.jallcom.2012.02.054

Maji B, Suresh KG, Chen X, Ramanujan RV (2012) Magnetic and magnetocaloric properties of ball milled Nd5Ge3. J Appl Phys 111:073905. doi:10.1063/1.3700243

Phan TL, Thanh TD, Zhang P, Yang DS, Yu SC (2013) The magnetic phase transition and magnetocaloric effect in Sm0.58Sr0.42MnO3 nanoparticles. Solid State Commun 166:32–37. doi:10.1016/j.ssc.2013.05.003

Than TD, Linh DC, Van HT, Ho TA, Manh TV, Bau LV, Phan TL, Yu SC (2015) Magnetocaloric effect in La0.7Ca0.25Ba0.05MnO3 nanocrystals exhibiting the crossover of first- and second-order magnetic phase transformation. Mater Trans 56:1316–1319. doi:10.2320/matertrans.MA201546

Biswas A, Chandra S, Stefanoski S et al (2015) Enhanced cryogenic magnetocaloric effect in Eu8Ga16Ge30 clathrate nanocrystals. J Appl Phys 117:033903. doi:10.1063/1.4906280

Kaya M, Rezaeivala M, Yuzuak E, Akturk S, Dincer I, Elerman Y (2015) Effects of size reduction on the magnetic and magnetocaloric properties of NdMn2Ge2 nanoparticles prepared by high-energy ball milling. Phys Status Solidi B-Basic Solid State Phys 252:192–197. doi:10.1002/pssb.201451127

de Santanna YVB, de Melo MAC, Santos IA, Coelho AA, Gama S, Cotica LF (2008) Structural, microstructural and magnetocaloric investigations in high-energy ball milled Ni2.18Mn0.82 Ga powders. Solid State Commun 148:289–292. doi:10.1016/j.ssc.2008.09.015

Paticopoulos SC, Caballero-Flores R, Franco V, Blázquez JS, Conde A, Knippling KE, Willard MA (2012) Enhancement of the magnetocaloric effect in composites: experimental validation. Solid State Commun 152:1590–1594. doi:10.1016/j.ssc.2012.05.015

Jones NJ, Ucar H, Ipus JJ, McHenry ME, Laughlin DE (2012) The effect of distributed exchange parameters on magnetocaloric refrigeration capacity in amorphous and nanocomposite materials. J Appl Phys 111:07A334. doi:10.1063/1.3679456

Nersessian N, Or SW, Carman GP (2004) Gd5Si2Ge2 composite for magnetostrictive actuator applications. Appl Phys Lett 84:4801–4803. doi:10.1063/1.1760891

Fujieda S, Fujita A, Fukamichi K (2003) Large magnetocaloric effects in NaZn13-type La(FexSi1 − x)13 compounds and their hydrides composed of icosahedral clusters. Sci Technol Adv Mater 4:339–346. doi:10.1016/j.stam.2003.07.002

Mandal K, Gutfleisch O, Yan A, Handstein A, Muller KH (2005) Effect of reactive milling in hydrogen on the magnetic and magnetocaloric properties of LaFe11.57Si1.43. J Magn Magn Mater 290:673–675. doi:10.1016/j.jmmm.2004.11.333

Mandal K, Pal D, Gutfleisch O, Kerschl P, Muller KH (2007) Magnetocaloric effect in reactively-milled LaFe11.57Si1.43HyLaFe11.57Si1.43Hy intermetallic compounds. J Appl Phys 102:053906. doi:10.1063/1.2775877

Lyubina J, Gutfleisch O, Kuz’min MD, Richter M (2008) La(Fe, Si)13-based magnetic refrigerants obtained by novel processing routes. J Magn Magn Mater 320:2252–2258. doi:10.1016/j.jmmm.2008.04.116

Sun NK, Xu SN, Li D, Zhang ZD (2011) Magnetocaloric effect and size-effect related thermal hysteresis reduction in MnAs1-xPx compounds. Phys Status Solidi A-Appl and Mater Sci 208:1950–1952. doi:10.1002/pssa.201026735

Yoshizawa Y, Oguma S, Yamauchi K (1988) New Fe-based soft magnetic alloys composed of ultrafine grain structure. J Appl Phys 64:6044–6046. doi:10.1063/1.342149

Kirchner A, Grunberger W, Gutfleisch O, Neu V, Muller KH, Schultz L (1998) A comparison of the magnetic properties and deformation behaviour of Nd-Fe-B magnets made from melt-spun, mechanically alloyed and HDDR powders. J Phys D-Appl Phys 31:1660–1666. doi:10.1088/0022-3727/31/14/008

Moreno LM, Blázquez JS, Ipus JJ, Conde A (2014) Amorphization and evolution of magnetic properties during mechanical alloying of Co62Nb6Zr2B30: dependence on starting boron microstructure. J Alloy Compd 585:485–490. doi:10.1016/j.jallcom.2013.09.191

Ipus JJ, Blázquez JS, Lozano-Pérez S, Conde A (2009) Microstructural evolution characterization of Fe–Nb–B ternary systems processed by ball milling. Philos Mag 89:1415–1423. doi:10.1080/14786430902984566

Doyle PA, Turner PS (1968) Relativistic Hartree-Fock X-ray and electron scattering factors. Acta Crystallogr A 24:390–397. doi:10.1107/S0567739468000756

Ipus JJ, Blázquez JS, Conde CF, Borrego JM, Franco V, Lozano-Pérez S, Conde A (2014) Relationship between mechanical amorphization and boron integration during processing of FeNbB alloys. Intermetallics 49:98–105. doi:10.1016/j.intermet.2014.01.018

Wijn HPJ (1991) Landolt-Börnstein: Magnetische Eigenschaften von Metallen. Springer, Berlin

Lozano-Pérez S (2008) A guide on FIB preparation of samples containing stress corrosion crack tips for TEM and atom-probe analysis. Micron 39:320–328. doi:10.1016/j.micron.2007.12.003

Liu XB, Liu XD, Altounian Z, Tu GH (2005) Phase formation and structure in rapidly quenched La(Fe0.88Co0.12)13 − xSix alloys. J Alloy Compd 397:120–125. doi:10.1016/j.jallcom.2005.01.022

Tarasov LP (1939) Ferromagnetic anisotropy of iron and iron-rich silicon alloys. Phys Rev 56:1231–1240. doi:10.1103/PhysRev.56.1231

Hill HH, Ellinger FH (1971) The effective size of americium dissolved in lanthanum. J Less-Common Met 23:92–94. doi:10.1016/0022-5088(71)90013-0

Thaljaoui R, Boujelben W, Pękała K, Pękała M, Cheikhrouhou-Koubaa W, Cheikhrouhou A (2013) Magnetocaloric study of monovalent-doped manganites Pr0.6Sr0.4 − xNaxMnO3 (x = 0–0.2). J Mater Sci 48:3894–3903. doi:10.1007/s10853-013-7191-2

Belkahla A, Cherif K, Dhahri J, Hlil EK (2016) Magnetic, magnetocaloric properties, and critical behavior in a layered perovskite La1.4(Sr0.95Ca0.05)1.6Mn2O7. J Mater Sci 51:7636–7651. doi:10.1007/s10853-016-0046-x

Coey JMD (2010) Magnetism and magnetic materials. Cambridge University Press, New York

Romero-Muñiz C, Ipus JJ, Blázquez JS, Franco V, Conde A (2014) Influence of the demagnetizing factor on the magnetocaloric effect: critical scaling and numerical simulations. Appl Phys Lett 104:252405. doi:10.1063/1.4885110

Moreno-Ramírez LM, Ipus JJ, Franco V, Blázquez JS, Conde A (2015) Analysis of magnetocaloric effect of ball milled amorphous alloys: demagnetizing factor and Curie temperature distribution. J Alloy Compd 622:606–609. doi:10.1016/j.jallcom.2014.10.134

Ipus JJ, Moreno-Ramirez LM, Blázquez JS, Franco V, Conde A (2014) A procedure to extract the magnetocaloric parameters of the single phases from experimental data of a multiphase system. Appl Phys Lett 105:172405. doi:10.1063/1.4900790

Franco V, Blázquez JS, Conde A (2006) Field dependence of the magnetocaloric effect in materials with a second order phase transition: a master curve for the magnetic entropy change. Appl Phys Lett 89:222512. doi:10.1063/1.2399361

Blázquez JS, Moreno-Ramírez LM, Ipus JJ, Kiss LF, Kaptás D, Kemény T, Franco V, Conde A (2015) Effect of α-Fe impurities on the field dependence of magnetocaloric response in LaFe11.5Si1.5. J Alloy Compd 646:101–105. doi:10.1016/j.jallcom.2015.06.085

Acknowledgements

Spanish MINECO and EU FEDER (Projects MAT 2013-45165-P), AEI/FEDER-UE (Project MAT-2016-77265-R) and the PAI of the Regional Government of Andalucía. L.M. Moreno-Ramírez acknowledges a FPU fellowship from the Spanish MECD.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Blázquez, J.S., Ipus, J.J., Moreno-Ramírez, L.M. et al. Ball milling as a way to produce magnetic and magnetocaloric materials: a review. J Mater Sci 52, 11834–11850 (2017). https://doi.org/10.1007/s10853-017-1089-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1089-3