Abstract

Metamagnetic shape memory alloys are a unique class of materials capable of large magnetic field-induced strain due to reverse martensitic phase transformation. A precondition for large shape change is martensite deformation, which heavily depends on microstructure. Elucidation of microstructure is therefore indispensable for strain control and deformation mechanics in such systems. The current paper reports on a self-accommodated martensitic microstructure in metamagnetic Ni50Mn37.5Sn12.5 single crystal. The microstructure here is hierarchically organised at three distinct levels. On a large scale, martensite plate colonies, distinguished by intercolony boundaries, group individual martensitic plates. Plates are separated by interplate boundaries and deviate by 2.2° from an ideal twin relation. On the lower scale, plates are composed of subplate twins. Conjugation boundaries separating two pairs of twins arise in relation to a subplate microstructure. Modulation boundaries separating two variants with perpendicular modulation directions and with parallel c-axes also appear. Mechanical training frees larger plates from fine subplate microtwins bringing macro-lamellae into twin relation, what then permits further detwinning until a single variant state.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

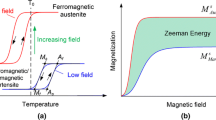

Research into Ni–Mn–(Sn, In, Sb) metamagnetic shape memory alloys has flourished since the discovery of the magnetic field-induced shape recovery by reverse martensitic phase transition in Ni–Co–Mn–In alloy [1]. It was further stimulated by the observation of giant magnetoresistance, magnetocaloric and more recently a large elastocaloric effect found in i.a. Ni–Mn–Sn system, which make these materials interesting for variety of functional applications [2,3,4]. In general, this unique behaviour originates in the thermo-elastic martensitic phase transition (MPT) between austenite and martensite phases, and the driving force is the Zeeman energy (ΔM·H) receiving contribution from the saturation magnetisation difference between the parent and product phase [5]. Earlier studies on Ni50Mn50−x Sn x alloys reveal that for critical 5 ≤ x ≤ 25 concentration range, the Heusler L21 austenite phase thermally transforms into martensite, depending on Sn content having 10 M, 14 M, 4O and L10 structures [6,7,8]. In general, on a mesoscopic scale the resultant martensite phase shows a hierarchical, self-accommodated microstructure composed of a mixture of different symmetry-related martensite variants organised at various length measures in order to reduce the overall transformation strain [9,10,11]. Martensite variants according to the Bain transformation matrix for a typical cubic to tetragonal transformation refer to the different crystallographically equivalent orientations of the tetragonal structure with the c-axis parallel to the three main axes of the cubic austenite. Due to symmetry relations, the number of such possible variants depends on the number of rotations in the austenite and martensite point groups leading to 3 variants for cubic (\( Fm\overline{3} m \)) to tetragonal (\( I\frac{4}{m}mm) \), 6 for cubic (\( Fm\overline{3} m \)) to orthorhombic (Pmma) and 12 for cubic (\( Fm\overline{3} m \)) to monoclinic (P2/m) transformations [10]. Detailed understanding of the resulting martensite microstructure is paramount for the control of twin-boundary mobility and thus overall mechanical properties of the low-temperature martensite phase, which by analogy to conventional shape memory alloys requires pre-deformation by an external loading in order to realise the shape recovery accompanied by an output stress. The pre-deformation is mediated by the detwinning mechanism, operational during the training process often applied to harvest a single variant martensite state and conducted by a sequence of uniaxial compression tests along the <001> directions referred to the austenite phase [12, 13]. The initial self-accommodated microstructure as well as the detwinning process has been elucidated in more detail for magnetic Ni–Mn–Ga alloys, while considerably less attention has been called in this regard to Ni–Mn–(Sn, In, Sb) alloys [14,15,16,17,18,19,20,21,22,23]. More recently, attempts to study variant organisation and mechanical detwinning have been performed for Ni50Mn38Sn12 [24] and Ni2Mn1.44In0.56 polycrystalline alloys [25], which were found to contain no nanotwins inside larger, misoriented plates. In the current paper, the self-accommodated and pre-strained microstructure is disclosed in Ni50Mn37.5Sn12.5 single crystal with a modulated 4 M martensite structure, which is capable of near the theoretical limit 7.9% longitudinal strain [26]. It is demonstrated that like most MSMA, Ni50Mn37.5Sn12.5 single crystal is not free from an internal sublamellar structure of fine twins resembling the typical “twins within twins” microstructure [10]. This is further in line with more recent reports [27], showing that during the training process, the initial detwinning of these fine twins within each misoriented macro-lamella is critical for the adjacent macro-lamellae to subsequently attain twin relation, what thereafter enables continued detwinning until the allowed limit.

Experimental

Single crystal with Ni50Mn37.5Sn12.5 nominal composition has been obtained by the Bridgman method. More details of the process can be found elsewhere [26]. The specimen undergoes MPT at martensite start temperature M s = 329 K and is at the martensite phase below martensite finish M f = 308 K. The lattice parameters of the monoclinic (90.2°) 4 M martensite phase are as follows: a = 6.066, b = 6.064 and c = 5.565 Å, and they have been confirmed with synchrotron high-energy X-ray radiation (87.1 keV, λ = 0.14236 Å) at the beamline Petra P07B at DESY, Germany. Mechanical training was performed on a parallelepiped specimen with 4.15 × 1.7 × 2.73 mm dimensions employing an Instron testing machine. It involved a sequence of uniaxial compression tests along <001> crystallographic directions, see for details [12, 26]. Tests were conducted at room temperature under a compressive stress of up to 250 MPa and at a strain rate of 10−3 s−1. The microstructure was studied using backscattered electron diffraction technique (EBSD) on high-resolution field emission FEI Quanta 3D instrument equipped with an EBSD detector and with Tecnai G2 (200 kV) transmission electron microscope (TEM). All EBSD maps are presented in the so-called all Euler colour coding, where different colours represent different orientations. Prior to EBSD measurement, the surface of the sample was subjected to electrochemical etching in order to remove surface stress and damage introduced during grinding and polishing. Thin foils for TEM examination were produced first by slicing the specimen (circa 0.15 mm thick) along the {001}-type plane referred to the austenite phase with a precision wire saw, mechanically grinding it and finally electropolishing using TenuPol-5 double-jet electropolisher and an electrolyte of nitric acid (1/3 vol.) and methanol (2/3 vol.) at 240 K and 20 V. All planes and directions presented in this paper are given in the so-called cubic coordinated system (CCS) built-up of a tetragonal lattice whose principal axes are aligned parallel with main axes of the cubic L21 phase. Tetragonal approximation is applied for EBSD measurement instead of the accurate crystallographic description in order to avoid misindexed points due to minor difference between a- and b-axes and nearly 90° unit cell angle, what escapes the resolution capacity of the EBSD indexing system. This assumption, however, does not alter microstructure analysis; it only brings up fewer details in the variant spectrum [13, 28].

Results

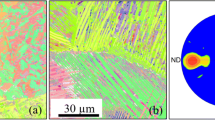

The thermally produced self-accommodated microstructure of martensite in Ni50Mn37.5Sn12.5 single crystal shows hierarchy at three different levels. On the macroscopic scale, the coarse martensite plates or macro-lamellae, corresponding to different martensite variants, are organised in colonies separated by intercolony boundaries (ICBs) such as those marked with an orange dashed line in Fig. 1a. The size of colonies is considerable and extends to a mm range. This is mainly related to a single-crystalline nature of the specimen, where lack of grain boundaries makes the self-accommodation process more easy. Otherwise, variant selection and distribution in polycrystalline materials are sensitive to grain size and processing route [29]. Macro-lamellae show up in two kinds of morphologies. Straight lamellae run across the entire colony, while bent and bifurcated ones bearing signs of pronounced branching terminate at a shorter distance from ICB. This behaviour is related to minimisation of elastic energy at the martensite–austenite and martensite–martensite interface at various stages of the transformation. Close to the interface, the system gains elastic advantage from structure refinement, whereas far from the interface, fine structure earns the system surface energy penalty; hence, coarsening is preferred [30]. Depending on the colony, martensite plates are inclined with respect to the edge of the picture frame at different angles between 0 and 180°. Lamellae in the EBSD map (Fig. 1) are coloured according to their orientations. It, henceforth, becomes evident from the colour pattern that there exist primarily two alternating martensitic variants in each colony. The plates are separated by interplate boundaries (IPBs), marked with a black, dashed line in Fig. 1a, and they are not twin related. Detailed pole figure analysis (Fig. 2a) reveals that the {101} planes, which are parallel to IPBs since the latter are derived from the habit planes due to cubic to tetragonal transition, are misoriented by circa 2.2°. This is also evident from the correlated misorientation angle line profile given in Fig. 3a where the misorientation between large macro-lamellae is estimated at 87.2°, which is circa 2.2° away from the ideal misorientation angle between two twined plates with these lattice constants calculated as \( 2\arctan \frac{c}{a} = \, 85.09^\circ \). In this scenario, lack of twin relation between large plates excludes the possibility of detwinning during mechanical loading on large scale. Simultaneously, the crystal turns out to be susceptible to training, as will be shown later, what implies that the primary deformation mode has to occur on a somewhat finer length scale suggesting the presence of a subtle microstructure. In addition, slight change in colour within individual macro-lamella signifies the change in orientation, evidencing the existence of more than one orientation within a single plate. This combination may be associated, as often observed, with the occurrence of a smaller substructure within the larger plates, virtually undetectable for the EBSD measurement with low resolution. In order to verify this suspicion, image quality analysis as well as a higher-resolution (50-nm step size) EBSD measurement (Fig. 1b) was conducted and it was confirmed that each single macro-lamella contains finer domains. According to colour coding, these fine domains are dominated by two orientations and they are twin related, due to shared {101} crystallographic plane (Fig. 2b). Therefore, the boundaries separating fine domains are twin boundaries (TBs), marked with a green, dashed line in Fig. 1b. Fine twins in the middle plate in Fig. 1b are tilted to approximately 45° with respect to IPBs (marked in the image), what indicates that TBs are in the edge-on position allowing for determination of the relative distribution between the two variants. The distribution contribution of each of the two variants can be estimated from the misorientation angle line profile given in Fig. 3b (the inset in that figure shows misorientaion angle line distribution at a shorter distance for clarity). First of all, it is clear that the orientation within the individual fine variant is constant and the misorientation angle across TB between two neighbouring twins is 85° around <010> rotation axes, which corresponds to an ideal twin relation at current lattice parameters. The estimated volume fraction is 0.55 and 0.45 between variants A and B, respectively. Hereafter, “plates” or “macro-lamellae” terms refer to larger martensite plates, whereas “fine twins” term is reserved for sublamella structure. Owing to the spatial resolution limit of the EBSD technique, more detailed TEM analysis has been conducted to verify the initial macroscopic picture of the studied microstructure.

EBSD map of the self-accommodated 4 M martensite microstructure in Ni50Mn37.5Sn12.5 single crystal. Intercolony boundaries (ICBs) separate groups of martensite plates with varying inclination angle with respect to the picture frame, whereas interplate boundaries (IPBs) separate large martensite plates within individual colony. Conjugation boundaries (CBs) separate two pairs of twins, with their twinning planes perpendicular to one another, within a single large martensite plate. Twin boundaries (TBs) separate twins

Figure 4a illustrates typical martensitic morphology with three microdomains separated by straight interplate boundaries. Bright field (BF) image in Fig. 4a taken off the [010] zone axis further marks fine substructural striations present within each of the individual unit plates. These appear as a set of parallel, close but randomly spaced faults, characteristic for modulated structures, and their orientation helps to distinguish between different martensite plates [31]. The SADP (top inset in Fig. 4a) taken from the domain A to the left shows a single variant with zone axis along [010]. The SADP (bottom inset in Fig. 4a) from across the boundary shows the (202) diffraction spots of variants A and B completely overlapping along [010] zone axis with (\( 20\overline{2} \)) reflection strictly perpendicular to the interplate boundary. This indicates twin orientation relation with the TB parallel to the {202} planes. The thickness of the microtwins varies considerably, as observed during TEM examination. Figure 4b shows BF image taken along the [010] zone axis—edge on—with the relevant DF images obtained using g = 202A (c) and g = \( \overline{2} 02_{\text{B}} \) (d) reflections corresponding to variants A and B, respectively, along [010] zone axis, see SADP in the inset in Fig. 4b.

Nanotwinned structure of thermally induced 4 M martensite. TEM BF image (a) taken from across twinned domains marked as A and B (BF taken off the [010] zone axis for clarity). Corresponding SADPs (insets) from variant A and from across A and B superimposed along [010] zone axis (c). TEM BF and DF images (b)–(d) showing the plate group configuration of nanotwinned domains in self-accommodated 4 M martensite. TEM DF images were taken from 202 and \( \overline{2} 02 \) reflections of variants A and B, denoted as 1 and 2, respectively, at [010] zone axis, see SADP inset (b)

The presence of subplate twins is often related to the existence of conjugated systems, where two pairs of twins with their twining planes nearly perpendicular to one another meet at the so-called conjugation boundary (CB) [20, 32]. An example of CB is shown in Fig. 1c. The change in orientation across the CB is responsible for the above-mentioned change in colour inside some lamellae as seen in EBSD maps. This effect is related to an interchange between two conjugated planes (Fig. 1c). It is further linked with IPB bending across the CB, which involves lattice rotation around (010) pole by a certain angle, in this instance of 3°–3.5° measured for two major variants across CB. The angle manifests itself also in Fig. 3a—marked with arrows. These two macroscopically detectable characteristics of CB can serve as an indirect evidence for the fact that the coarse lamella breaks into a substructure of finer domains. A closer look with a TEM at CB confirms the presence of two pairs of martensite twins distributed across the CB (Fig. 5). The twinning planes of the two twin pairs are aligned almost perpendicular to one another and intersect at CB. SADP taken from the twin pair to the left denoted as 1 is shown in Fig. 5b. Since the pairs of twins are rotated (3°–3.5°) relative to each other, eventually four orientations are produced as illustrated in Fig. 5c. CB has typical step-like character originating in two pairs of conjugate twins stepping from both sides of the boundary. It also shows coarsening while moving from the top near IPB to the inner part of the lamellae. For a more thorough study of CB and the proposed mechanism for its removal under compression, see [20, 27, 33].

Another type of boundary interface frequently encountered in MSMA is the modulation boundary (Fig. 6a). In general, modulation is related to the periodic displacement of lattice planes along the (110)\( \left[ {1\overline{1} 0} \right]_{\text{CCS}} \) system. The direction of the modulation is closely parallel to the diagonal of the basal plane of the martensite unit cell, whose shortest c-axis points in the direction perpendicular to the modulation direction. This allows for two possible, equivalent modulation directions [34]. BF image taken with the specimen tilted off the [001] axis in Fig. 6a shows striations arising from stacking faults and a wavy character of the MB. The corresponding SADPs presented in Fig. 6b–d and taken along the [001] zone axis expose characteristic additional satellite spots between fundamental reflections typical for modulated structures and in this instance attributable to the 4 M martensite. SADP in Fig. 6b is taken from the top part of the image, while that in Fig. 6d from the bottom part. SADP in Fig. 6c is taken from across the boundary interface. It is evident that the modulation direction rotates by circa 90° across the interface, confirming that the boundary separates two variants with modulation directions nearly normal to one another (~90.3°). High-resolution image in Fig. 6e reveals a step-like character of the boundary interface. It is also well visible at higher magnification in Fig. 7a where the step-like feature is traced with a yellow dashed line. The stacking sequence of the consecutive atomic planes appears inhomogeneous and shows (\( 3\overline{1} \)) and (\( 2\overline{2} \)) stacking periodicity according to Zhdanov notation (Fig. 7b) [35]. This is suggested by the intensity line profiles inserted in Fig. 7b and recorded over the areas marked with red rectangle frames on the same image. The relative intensity of the peaks correspondingly changes in the profiles. Alternatively, this effect could be ascribed to phase contrast difference resulting from varying foil thickness or thin foil damage. Overall, it is clear that the self-accommodated microstructure shows considerable level of complexity. For illustration of all the different domain types and interfaces, a schematic is presented in Fig. 8.

TEM HREM micrograph and its FFT taken along the modulation interface showing step-like nature of this interface (a) and a magnified HREM image along with FFT recorded at a modulated area. Insets in b show intensity line profiles depicting disordering in the stacking sequence of (\( 3\overline{1} \)) and (\( 2\overline{2} \)) according to Zhdanov notation. All zone axes ‖[001]

Schematic representation of self-accommodated hierarchical microstructure illustrating various domain types and boundary types in the studied Ni–Mn–Sn metamagnetic single crystal. ICBs separate groups of martensite variants; IPBs separate large martensite plates; TBs separate twins present within the plates; CBs separate two pairs of twins with their twinning planes perpendicular to each other; MBs separate modulation twins with lattice modulation along one of the two possible modulation directions indicated by MD1 and MD2 (a, c—lattice constants)

In order to evaluate the changes in the self-accommodated microstructure upon training, a sequence of uniaxial compressions along <001> directions of the Ni50Mn37.5Sn12.5 single crystal was performed. The compression directions in the specimen coordinate system corresponding to A-, B- and C-axes of the parallelepiped specimen are schematically shown in the inset (bottom right) in Fig. 9a. The first compression was performed along the B-axis, the second along the C-axis, while the third along the A-axis. The inset (top right) in Fig. 9a shows as an example shortening and elongation upon subsequent compressions of the C-axis. More details on training of the Ni50Mn37.5Sn12.5 single crystal can be found elsewhere [26]. The fourth compression was performed along the C-axis, and it was terminated at 54% of the total strain acquired during the second compression test, what is illustrated in Fig. 9a showing the stress versus strain curves for the two tests with load applied along the C-axis. The subsequent EBSD analysis (Fig. 9b) revealed that the sublamellar microtwins initially present in the sample have been removed during the training process and larger plates assumed twin relation. The misorientation angle decreased to 85° (Fig. 3c). This is consistent with the literature, where it is found that microstructure reorientation during loading initiates with first detwinning of internal twins [27, 36]. It is also evident from EBSD measurement that larger plates more favourably oriented with respect to the applied load grow at the expense of the less favourably oriented ones as is also visible from the misorientation angle profile (Fig. 3), especially in comparison with the pre-strained state. Twin expansion is also shown in BF image (Fig. 10a, b), taken from the sample surface parallel to C-axis, following the fourth compression test. It is seen that the more favourably oriented variant nucleates and grows consuming the less favourably oriented one. It is found by other researchers that detwinning process proceeds via the movement of twinning dislocations advancing on successive twin planes and converting one variant into another [36, 37]. The expanding twin advances into the matrix with a characteristic tip due to a possible dislocation pile up (Fig. 10a). Moving twinning dislocations leave traces behind showing up as straight lines (Fig. 10b). HREM image in Fig. 10c taken from across twin interface reveals the presence of some strain contrast near the boundary suggesting local incoherency at the matching plates’ interface possibly related to interfacial dislocations or modulations, which has not been visibly affected by training (Fig. 10d) [38].

Stress versus strain curves (a) recorded during uniaxial compression tests performed on self-accommodated Ni49.5Mn38.4Sn12.2 single crystal at the martensite phase. For clarity, only second and fourth compressions both with load applied along the longer C-axis are shown. EBSD map (b) of the half-trained 4 M microstructure

Structure of the pre-trained 4 M martensite after fourth compression test along the C-axis, where the load was removed at the 53% of the initial strain (second compression). BF images showing disappearance of the less favourably oriented martensite variant; straight lines are traces left by moving dislocations (a); plates of the favoured variant nucleate and progress within the disappearing variant (b). HREM image along a twin boundary showing an incoherent twin interface (c). HREM image of the modulation boundary (d)

Conclusions

Upon the martensitic transformation, Ni50Mn37.5Sn12.5 single crystal transforms into a martensite state with three distinct levels of hierarchically organised microstructure. At the macro-scale, large martensite plates are arranged into variant colonies separated by intercolony boundaries. Within colonies, large plates are separated by interplate boundaries deviating by 2.2° from an ideal twin relation. At the lower scale, large macro-plates break into finer subplate structure composed of finer twins. The presence of differently oriented groups of twins within single macro-plate region results in conjugated boundaries separating two twin-related pairs of twins. Another type of twin boundary is the modulation boundary separating two variants with modulation directions perpendicular to one another and with common c-axis. Training process removes fine microtwin structure and brings macro-lamellae into twin relation. Subsequently, this enables continued detwinning of large plates until single variant state is obtained.

References

Kainuma R, Imano Y, Ito W, Sutou Y, Morito H, Okamoto S, Kitakami O, Oikawa K, Fujita A, Kanomata T, Ishida K (2006) Magnetic-field-induced shape recovery by reverse phase transformation. Nat Lett 439:957–960

Khan M, Pathak AK, Paudel MR, Dubenko I, Stadler S, Ali N (2008) Magnetoresistance and field-induced structural transitions in Ni50Mn50−x Sn x Heusler alloys. J Magn Magn Mater 320:L21–L25

Czaja P, Chulist R, Szczerba MJ, Przewoźnik J, Olejnik E, Chrobak A, Maziarz W, Cesari E (2016) Magnetostructural transition and magnetocaloric effect in highly textured Ni–Mn–Sn alloy. J Appl Phys 119:165102–165106

Sun W, Liu J, Lu B, Li Y, Yan A (2016) Large elastocaloric effect at small transformation strain in Ni45Mn44Sn11 metamagnetic shape memory alloys. Scr Mater 114:1–4

Karaca HE, Karaman I, Basaran B, Ren Y, Chumlyakov YI, Maier HJ (2009) Magnetic field-induced phase transformation in NiMnCoIn magnetic shape-memory alloys—a new actuation mechanism with large work output. Adv Funct Mater 19:983–998

Sutou Y, Imano Y, Koeda N, Omori T, Kainuma R, Ishida K, Oikawa K (2004) Magnetic and martensitic transformations of NiMnX(X = In, Sn, Sb) ferromagnetic shape memory alloys. Appl Phys Lett 85:4358–4360

Krenke T, Acet M, Wassermann EF, Moya X, Manosa L, Planes A (2005) Martensitic transitions and the nature of ferromagnetism in the austenitic and martensitic states of Ni–Mn–Sn alloys. Phys Rev B 72:014412-1–014412-9

Brown PJ, Gandy AP, Ishida K, Kainuma R, Kanomata T, Neumann K-U, Oikawa K, Ouladdiaf B, Ziebeck KRA (2016) The magnetic and structural properties of the magnetic shape memory compound Ni2Mn1.44Sn0.56. J Phys Condens Matter 18:2249–2259

Otsuka K, Wayman CM (1998) Shape memory materials. Cambridge University Press, Cambridge

Bhattacharya K (2003) Microstructure of martensite. Oxford University Press, Oxford

Mullner P, King AH (2010) Deformation of hierarchically twinned martensite. Acta Mater 58:5242–5261

Szczerba MJ, Chulist R, Kopacz S, Szczerba MS (2014) Effect of initial plastic strain on mechanical training of non-modulated Ni–Mn–Ga martensite structure. Mater Sci Eng A 611:e313–e319

Chulist R, Pagounis E, Bohm A, Oertel C-G, Skrotzki W (2012) Twin boundaries in trained 10 M Ni–Mn–Ga single crystals. Scr Mater 67:364–367

Han M, Bennett JC, Gharghouri MA, Chen J, Hyatt CV, Mailman N (2008) Microstructure characterization of the non-modulated martensite in Ni–Mn–Ga alloy. Mater Charact 59:764–768

Han M, Kong FF (2008) Twin boundary structure of the modulated variants in a Ni–Mn–Ga alloy. J Alloys Compd 458:218–222

Li Z, Zhang Y, Esling C, Zhao X, Zuo L (2011) Twin relationships of 5 M modulated martensite in Ni–Mn–Ga alloy. Acta Mater 59:3390–3397

Nishida M, Hara T, Matsuda M, Ii S (2008) Crystallography and morphology of various interfaces in Ti–Ni, Ti–Pd, and Ni–Mn–Ga shape memory alloys. Mater Sci Eng A 481–482:18–27

Matsuda M, Yasumoto Y, Hashimoto K, Hara T, Nishida M, Nishida M (2012) Transmission electron microscopy of twins in 10 M martensite in Ni–Mn–Ga ferromagnetic shape memory alloy. Mater Trans 53:902–906

Chulist R, Straka L, Lanska N, Soroka A, Sozinov A, Skrotzki W (2013) Characterization of mobile type I and type II twin boundaries in 10 M modulated Ni–Mn–Ga martensite by electron backscatter diffraction. Acta Mater 61:1913–1920

Muntifering B, Pond RC, Kovarik L, Browning ND, Mullner P (2014) Intra-variant substructure in Ni–Mn–Ga martensite: conjugation boundaries. Acta Mater 71:255–263

Chulist R, Skrotzki W, Oertel C-G, Bohm A, Potschke M (2010) Change in microstructure during training of a Ni50Mn29Ga21 bicrystal. Scr Mater 63:548–551

Chulist R, Straka L, Sozinov A, Lippmann T, Skroztki W (2013) Modulation reorientation in 10 M Ni–Mn–Ga martensite. Scr Mater 68:671–674

Heczko O, Straka L, Seiner H (2013) Different micorstructures of mobile twin boundaries in 10 M modulated Ni–Mn–Ga martensite. Acta Mater 61:622–631

Lin C, Yan H, Zhang Y, Esling C, Zhao X, Zuo L (2016) Crystal structure of modulated martensite and crystallographic correlations between martensite variants of Ni50Mn38Sn12. J Appl Cryst 49:1276–1283

Yan H, Yang B, Zhang Y, Li Z, Esling C, Zhao X, Zuo L (2016) Variant organization and mechanical detwinning of modulated martensite in Ni–Mn–In metamagnetic shape-memory alloys. Acta Mater 111:75–84

Czaja P, Szczerba MJ, Chulist R, Bałanda M, Przewoźnik J, Chumlyakov YI, Schell N, Kapusta C, Maziarz W (2016) Martensitic transition, structure and magnetic anisotropy of martensite in Ni–Mn–Sn single crystal. Acta Mater 118:213–220

Szczerba MJ, Chulist R (2015) Detwinning of a non-modulated Ni–Mn–Ga martensite: from self-accommodated microstructure to single crystal. Acta Mater 85:67–73

Li ZB, Zhang YD, Esling C, Zhao X, Zuo L (2011) Twin relationships of 5 M modulated martensite in Ni–Mn–Ga alloy. Acta Mater 59:3390–3397

Chulist R, Bohm A, Oertel C-G, Skrotzki W (2014) Self-accommodation in polycrystalline 10 M Ni–Mn–Ga martensite. J Mater Sci 49:3951–3955. doi:10.1007/s10853-013-7996-z

Kohn RV, Muller S (1992) Branching of twins near an austenite-twinned-martensite interface. Philos Mag 66:697–715

Zhang J, Cai W, Zheng Y, Zhao L (1998) Type II twins and their deformation characteristics in 18R martensite in a Cu–Zn–Al alloys. Mater Lett 34:351–355

Szczerba MJ (2015) Non-modulated martensite microstructure with internal nanotwins in Ni–Mn–Ga alloys. Arch Metall Mater 60:2267–2270

Muntifering B, Kovarik L, Browning ND, Pond RC, Knowlton WB, Mullner P (2016) Stress-assisted removal of conjugation boundaries in non-modulated Ni–Mn–Ga by coordinated secondary twinning. J Mater Sci 51:457–466. doi:10.1007/s10853-015-9236-1

Straka L, Heczko O, Seiner H, Lanska N, Drahokoupil J, Soroka A, Fahler S, Hanninen H, Sozinov A (2011) Highly mobile twinned interface in 10 M modulated Ni–Mn–Ga martensite: analysis beyond the tetragonal approximation of lattice. Acta Mater 59:7450–7463

Cesari E, Pons J, Santamarta R, Segui C, Chernenko VA (2004) Ferromagnetic shape memory alloys: an overview. Arch Metall Mater 49:779–789

Zarubova N, Ge Y, Heczko O, Hannula S-P (2013) In situ TEM study of deformation twinning in Ni–Mn–Ga non-modulated martensite. Acta Mater 61:5290–5299

Zarubova N, Ge Y, Gemperlova J, Gemperle A, Hannula S-P (2012) Dislocation mechanism of twinning in Ni–Mn–Ga. Funct Mater Lett 5:1250006-1–1250006-4

Erkartal B, Duppel V, Niemann R, Schultz L, Fahler S, Schurmann U, Kienle L (2012) Structure and composition of magnetocaloric Ni–Mn–In–Co thin films on the nanoscale—a TEM study. Adv Eng Mater 14:710–715

Acknowledgement

The financial support of the Polish National Science Centre (NCN)—Project Number: 2012/07/N/ST8/03918 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Czaja, P., Chulist, R., Szlezynger, M. et al. Self-accommodated and pre-strained martensitic microstructure in single-crystalline, metamagnetic Ni–Mn–Sn Heusler alloy. J Mater Sci 52, 5600–5610 (2017). https://doi.org/10.1007/s10853-017-0793-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-0793-3