Abstract

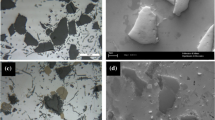

The firstly reported formation mechanism of TiC particles in TiC/Ni composites fabricated by in situ reactive infiltration process is presented. In this paper, the TiC/Ni composites were fabricated by in situ reactive infiltration and the formation mechanism of TiC particles during the process was investigated. The results show that the process includes two stages. In stage I, the Ti and graphite react and generate TiC x (x < 1) particles, which grow on the graphite sheets and form multilayer or a single-layer stacking morphology, depending on the position of graphite sheets. In stage II, the C/Ti ratio, particle size and morphology of TiC x particles are adjusted by the infiltrated metal through “dissolution–precipitation” process, and the final morphology of TiC particles in the metal matrix is decided by the initial C/Ti ratio, metal amount, and alloying elements.

Similar content being viewed by others

References

Miracle DB (2005) Metal matrix composites—from science to technological significance. Compos Sci Technol 65:2526–2540

Zheng BL, Topping T, Smugeresky JE, Zhou YZ, Biswas A, Baker D, Lavernia EJ (2010) The influence of Ni-coated TiC on laser-deposited IN625 metal matrix composites. Mater Trans A 41:568–573

Gopagoni S, Hwang JY, Singh ARP, Mensah BA, Bunce N, Tiley J, Scharf TW, Banerjee R (2011) Microstructural evolution in laser deposited nickel–titanium–carbon in situ metal matrix composites. J Alloy Compd 509:1255–1260

Hong C, Gu DD, Dai DH, Gasser A, Weisheit A, Kelbassa I, Zhong ML, Poprawee R (2013) Laser metal deposition of TiC/Inconel 718 composites with tailored interfacial microstructures. Opt Laser Technol 54:98–109

Borkar T, Sosa J, Hwang JY, Scharf TW, Tiley J, Fraser H, Banerjee R (2014) Laser-deposited in situ TiC-reinforced nickel matrix composites: 3D microstructure and tribological properties. JOM 66:935–942

Huang L, Wang HY, Qiu F, Jiang QC (2006) Synthesis of dense ceramic particulate reinforced composites from Ni–Ti–C, Ni–Ti–B, Ni–Ti–B4C and Ni–Ti–C–B systems via the SHS reaction, arc melting and suction casting. J Mater Sci Eng A 422:309–315

Qi Q, Liu Y, Huang ZR (2015) Promising metal matrix composites (TiC/Ni–Cr) for intermediate-temperature solid oxide fuel cell (SOFC) interconnect applications. Scr Mater 109:56–60

Wang HY, Jiang QC, Li XL, Wang JG (2003) In situ synthesis of TiC–Mg composites in magnesium. Scr Mater 48:1349–1354

Chen LQ, Dong Q, Zhao MJ, Bi J, Kanetake N (2005) Synthesis of TiC/Mg composites with interpenetrating networks by in situ reactive infiltration process. J Mater Sci Eng A 408:125–130

Tjong SC, Ma ZY (2000) Microstructural and mechanical characteristics of in situ metal matrix composites. Mater Sci Eng A 29:49–113

Dong Q, Chen LQ, Zhao MJ, Bi J (2004) Synthesis of TiC p reinforced magnesium matrix composites by in situ reactive infiltration process. Mater Lett 58:920–926

Dong Q, Chen LQ, Zhao MJ, Bi J (2004) Analysis of in situ reaction and pressureless infiltration process in fabricating TiC/Mg composites. J Mater Sci Technol 20(1):3–7

Omura N, Kobashi M, Choh T, Kanetake N (2002) Synthesis of TiC/aluminum composite by reactive infiltration process. Mater Sci Forum 396:271–276

Rambo CR, Travitzky N, Greil P (2015) Conductive TiC/Ti–Cu/C composites fabricated by Ti–Cu alloy reactive infiltration into 3D-printed carbon performs. J Compos Mater 49:1971–1976

Shi YL, Guo ZM, Hao JJ, Lin T, Zeng X (2012) Processing and abrasive wear study of Fe–Al2O3–TiC composite by pressureless Ti-activated reactive melt infiltration. Adv Mater Res 482–484:933–937

Qin QD, Zhao YG, Zhao Y, Cong PJ, Zhao YK (2008) Preparation of AlFeSiV compounds local reinforced Al matrix composite by pressureless reactive infiltration technique. Mater Sci Eng A 487:352–359

Wu CML, Han GW (2007) Synthesis of an Al2O3/Al co-continuous composite by reactive melt infiltration. Mater Charact 58:416–422

Choi Y, Rhee SW (1995) Effect of carbon sources on the combustion synthesis of TiC. J Mater Sci 30:4637–4644

Chu MG, Premkumar MK (1993) Mechanism of TiC formation in Al/TiC in situ metal-matrix composites. Mater Trans A 24:2803–2805

Jang JH, Lee CH, Heo YU, Suh DW (2012) Stability of (Ti, M)C (M = Nb, V, Mo and W) carbide in steels using first-principles calculations. Acta Mater 60:208–217

Jin SB, Shen P, Zou BL, Jiang QC (2009) Morphology evolution of TiC x grains during SHS in an Al–Ti–C system. Cryst Growth Des 9:646–649

Jin SB, Shen P, Zhou DS, Jiang QC (2012) A common regularity of stoichiometry-induced morphology evolution of transition metal carbides, nitrides, and diborides during self-propagating high-temperature synthesis. Cryst Growth Des 12:2814–2824

Li Y, Liu N, Zhang XB, Rong CL (2008) Effect of Mo addition on the microstructure and mechanical properties of ultra-fine grade TiC–TiN–WC–Mo2C–Co cermets. Int J Refract Met Hard Mater 26:190–196

Choi Y, Baik NI, Lee JS, Hong SI, Hahn YD (2001) Corrosion and wear properties of TiC/Ni–Mo composites produced by direct consolidation during a self-propagating high-temperature reaction. Compos Sci Technol 61:981–986

Acknowledgements

The authors are grateful for the financial support from Key Laboratory of Fine Ceramics and Superfine Structure of Shanghai Institute of Ceramics, C.A.S., and Chinese Academy of Sciences.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Qi, Q., Liu, Y., Zhang, H. et al. The formation mechanism of TiC particles in TiC/Ni composites fabricated by in situ reactive infiltration. J Mater Sci 51, 7038–7045 (2016). https://doi.org/10.1007/s10853-016-9994-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-9994-4