Abstract

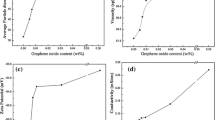

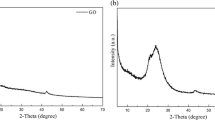

To study the dispersity of different amine-graphene oxide (amine-GO) in polymer matrix and the interfacial interactions between functionalized graphene oxide and matrix, two kinds of modifiers—organoamine- and aminosilane-coupling agents—were used to functionalize graphene nanosheets to obtain functionalized graphene oxide/waterborne polyurethane nanocomposites by in situ polymerization. The chemical structure, morphology, and interlayer space of amine-GO nanoplatelets were confirmed by FT-IR, Raman, TGA, XPS, TEM, AFM, and XRD. The dispersity behaviors between different amine-GOs and polymers were evaluated by FESEM. The thermal, mechanical, and hydrophobic properties of the nanocomposites were investigated by TGA, tensile testing machine, and water contact angle test, respectively. It was found that the tensile strength of nanocomposites was increased from 10.13 to 27.79 and 28.96 Mpa after the addition of amine-GO functionalized by APTMS and APTES, respectively. The better thermal stability and hydrophobicity of nanocomposites were also achieved by the addition of amine-GO, especially those modified by aminosilane-coupling agents. This study paves a new route for designing and developing chemically converted graphene oxide nanosheets/polymer nanocomposite materials by altering suitable amine-modifier to functionalize graphene oxide nanosheets and then optimizing the interphases between graphene oxide nanosheets and polymer matrices.

Similar content being viewed by others

References

Engels HW, Pirkl HG, Albers R et al (2013) Polyurethanes: versatile materials and sustainable problem solvers for today’s challenges. Angew Chem Int Ed 52:9422–9441

Wu G, Kong Z, Chen J et al (2014) Preparation and properties of waterborne polyurethane/epoxy resin composite coating from anionic terpene-based polyol dispersion. Prog Org Coat 77:315–321

Elrebii M, Mabrouk AB, Boufi S (2014) Synthesis and properties of hybrid alkyd–acrylic dispersions and their use in VOC-free waterborne coatings. Prog Org Coat 77:757–764

Wu Z, Wang H, Tian X et al (2014) Surface and mechanical properties of hydrophobic silica contained hybrid films of waterborne polyurethane and fluorinated polymethacrylate. Polymer 55:187–194

Li SC, Wang LW, Wang JY (2012) Study on properties of modified nano-ZnO/WPU hybrid material. Adv Mater Res 510:742–746

Ma XY, Zhang WD (2009) Effects of flower-like ZnO nanowhiskers on the mechanical, thermal and antibacterial properties of waterborne polyurethane. Polym Degrad Stab 94:1103–1109

Kuan HC, Ma CCM, Chang WP et al (2005) Synthesis, thermal, mechanical and rheological properties of multiwall carbon nanotube/waterborne polyurethane nanocomposite. Compos Sci Technol 65:1703–1710

Miklečić J, Blagojević SL, Petrič M et al (2015) Influence of TiO2 and ZnO nanoparticles on properties of waterborne polyacrylate coating exposed to outdoor conditions. Prog Org Coat 89:67–74

Awad S, Chen H, Chen G et al (2010) Free volumes, glass transitions, and cross-links in zinc oxide/waterborne polyurethane nanocomposites. Macromolecules 44:29–38

Kim YJ, Kim BK (2014) Synthesis and properties of silanized waterborne polyurethane/graphene nanocomposites. Colloid Polym Sci 292:51–58

Yang SY, Lin WN, Huang YL, Tien HW, Wang JY, Ma CCM, Li SM, Wang YS (2011) Synergetic effects of graphene platelets and carbon nanotubes on the mechanical and thermal properties of epoxy composites. Carbon 49:793–803

Seyedin MZ, Razal JM, Innis PC et al (2015) Achieving outstanding mechanical performance in reinforced elastomeric composite fibers using large sheets of graphene oxide. Adv Funct Mater 25:94–104

Li J, Ye F, Vaziri S et al (2013) Efficient inkjet printing of graphene. Adv Mater 25:3985–3992

Balandin AA, Ghosh S, Bao W et al (2008) Superior thermal conductivity of single-layer graphene. Nano Lett 8:902–907

Scheuermann GM, Rumi L, Steurer P et al (2009) Palladium nanoparticles on graphite oxide and its functionalized graphene derivatives as highly active catalysts for the Suzuki-Miyaura coupling reaction. J Am Chem Soc 131:8262–8270

Bunch JS, Verbridge SS, Alden JS et al (2008) Impermeable atomic membranes from graphene sheets. Nano Lett 8:2458–2462

Liang J, Huang Y, Zhang L et al (2009) Molecular-level dispersion of graphene into poly (vinyl alcohol) and effective reinforcement of their nanocomposites. Adv Funct Mater 19:2297–2302

AngeláRodriguez-Perez M, de Saja JA, AngeláLopez-Manchado M (2008) Functionalized graphene sheet filled silicone foam nanocomposites. J Mater Chem 18:2221–2226

Wang X, Hu Y, Song L et al (2011) In situ polymerization of graphene nanosheets and polyurethane with enhanced mechanical and thermal properties. J Mater Chem 21:4222–4227

Wang X, Xing W, Song L et al (2012) Fabrication and characterization of graphene-reinforced waterborne polyurethane nanocomposite coatings by the sol–gel method. Surf Coat Technol 206:4778–4784

Appel AK, Thomann R, Mülhaupt R (2012) Polyurethane nanocomposites prepared from solvent-free stable dispersions of functionalized graphene nanosheets in polyols. Polymer 53:4931–4939

Qian X, Song L, Yu B et al (2014) One-pot surface functionalization and reduction of graphene oxide with long-chain molecules: preparation and its enhancement on the thermal and mechanical properties of polyurea. Chem Eng J 236:233–241

Han S, Chun BC (2014) Preparation of polyurethane nanocomposites via covalent incorporation of functionalized graphene and its shape memory effect. Compos A Appl Sci Manuf 58:65–72

Li X, Cheng Y, Zhang H et al (2015) Efficient CO2 capture by functionalized graphene oxide nanosheets as fillers to fabricate multi-permselective mixed matrix membranes. ACS Appl Mater Interfaces 7:5528–5537

Liu F, Wu L, Song Y et al (2015) Effect of molecular chain length on the properties of amine-functionalized graphene oxide nanosheets/epoxy resins nanocomposites. RSC Adv 5:45987–45995

Du J, Lai X, Yang N et al (2010) Hierarchically ordered macro–mesoporous TiO2–graphene composite films: improved mass transfer, reduced charge recombination, and their enhanced photocatalytic activities. ACS Nano 5:590–596

Kim NH, Kuila T, Lee JH (2013) Simultaneous reduction, functionalization and stitching of graphene oxide with ethylenediamine for composites application. J Mater Chem A 1:1349–1358

Matsuo Y, Nishino Y, Fukutsuka T et al (2007) Introduction of amino groups into the interlayer space of graphite oxide using 3-aminopropylethoxysilanes. Carbon 45:1384–1390

Yang H, Li F, Shan C et al (2009) Covalent functionalization of chemically converted graphene sheets via silane and its reinforcement. J Mater Chem 19:4632–4638

Yadav SK, Cho JW (2013) Functionalized graphene nanoplatelets for enhanced mechanical and thermal properties of polyurethane nanocomposites. Appl Surf Sci 266:360–367

Liao K-H, Aoyama S, Abdala AA et al (2014) Does graphene change Tg of nanocomposites? Macromolecules 47:8311–8319

Cao Y, Feng J, Wu P (2010) Preparation of organically dispersible graphene nanosheet powders through a lyophilization method and their poly (lactic acid) composites. Carbon 48:3834–3839

Bharathidasan T, Narayanan TN, Sathyanaryanan S et al (2015) Above 170° water contact angle and oleophobicity of fluorinated graphene oxide based transparent polymeric films. Carbon 84:207–213

Acknowledgements

The authors gratefully acknowledge the financial supports from the Cooperative Innovation Foundation of Industry, Academy and Research Institutes (BY2013015-10, 2014023-08) in Jiangsu Province of China and the Fundamental Research Funds for the Central Universities (JUSRP51623A).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Hu, L., Jiang, P., Zhang, P. et al. Amine-graphene oxide/waterborne polyurethane nanocomposites: effects of different amine modifiers on physical properties. J Mater Sci 51, 8296–8309 (2016). https://doi.org/10.1007/s10853-016-9993-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-9993-5