Abstract

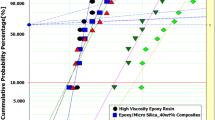

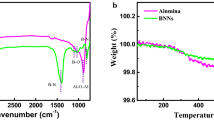

Development of polymer-based composites with simultaneously high thermal conductivity and breakdown strength has attracted considerable attentions owing to their important applications in both electronic and electric industries. In this study, we successfully design novel epoxy-based composites with nano-Al2O3/epoxy composite layer sandwiched between micro-Al2O3/epoxy composite layers, which show synergistically and significantly enhanced thermal conductivity and breakdown strength. Compared with the traditional composites, the bottleneck that both thermal conductivity and breakdown strength cannot be simultaneously enhanced can be overcome successfully. An optimized sandwiched alumina–epoxy composite with 70 wt% micro-Al2O3 fillers in the outer layers and 3 wt% nano-Al2O3 in the middle layer simultaneously displays a high thermal conductivity of 0.447 W m−1 K−1 (2.4 times of that of epoxy) and a high breakdown strength of 68.50 kV mm−1, which is 6.3 % higher than that of neat epoxy (64.45 kV mm−1). The experimental results on the thermal conductivity of multi-layered alumina–epoxy composites were in well accordance with the theoretical values predicted from the series conduction model. This novel technique simultaneously improves thermal conductivity and breakdown strength, which is of critical importance for design of perspective composites for electronic and electric equipments.

Similar content being viewed by others

References

Huang XY, Zhi CY, Jiang PK, Golberg D, Bando Y, Tanaka T (2013) Polyhedral oligosilsesquioxane-modified boron nitride nanotube based epoxy nanocomposites: an ideal dielectric material with high thermal conductivity. Adv Funct Mater 23(14):1824–1831. doi:10.1002/adfm.201201824

Wu GL, Cheng YH, Wang KK, Wang YQ, Feng AL (2016) Fabrication and characterization of OMMt/BMI/CE composites with low dielectric properties and high thermal stability for electronic packaging. J Mater Sci 27(6):5592–5599. doi:10.1007/s10854-016-4464-y

Jiraborvornpongsa N, Imai M, Yoshida K, Yano T (2013) Effects of trace amount of nanometric SiC additives with wire or particle shapes on the mechanical and thermal properties of alumina matrix composites. J Mater Sci 48(20):7022–7027. doi:10.1007/s10853-013-7511-6

Li Q, Chen L, Gadinski MR, Zhang SH, Zhang GZ, Li H, Haque A, Chen LQ, Jackson T, Wang Q (2015) Flexible high-temperature dielectric materials from polymer nanocomposites. Nature 523(7562):576–579. doi:10.1038/nature14647

Zhou YC, Chen YN, Wang H, Wong CP (2014) Creation of a multilayer aluminum coating structure nanoparticle polyimide filler for electronic applications. Mater Lett 119:64–67. doi:10.1016/j.matlet.2014.01.009

Khaleghi E, Torikachvili M, Meyers MA, Olevsky EA (2012) Magnetic enhancement of thermal conductivity in copper–carbon nanotube composites produced by electroless plating, freeze drying, and spark plasma sintering. Mater Lett 79:256–258. doi:10.1016/j.matlet.2012.03.117

Donnay M, Tzavalas S, Logakis E (2015) Boron nitride filled epoxy with improved thermal conductivity and dielectric breakdown strength. Compos Sci Technol 110:152–158. doi:10.1016/j.compscitech.2015.02.006

Wu GL, Cheng YH, Wang ZD, Wang K, Feng A (2016) In situ polymerization of modified graphene/polyimide composite with improved mechanical and thermal properties. J Mater Sci. doi:10.1007/s10854-016-5560-8

Wang ZB, Iizuka T, Kozako M, Ohki Y, Tanaka T (2011) Development of epoxy/BN composites with high thermal conductivity and sufficient dielectric breakdown strength Part I. Sample preparations and thermal conductivity. IEEE Trans Dielectr Electr Insul 18(6):1963–1972. doi:10.1109/TDEI.2011.6118634

Singha S, Thomas MJ (2008) Dielectric properties of epoxy nanocomposites. IEEE Trans Dielectr Electr Insul 15(1):12–23. doi:10.1109/T-DEI.2008.4446732

Yu JH (2011) Influence of nano-AlN particles on thermal conductivity, thermal stability and cure behavior of cycloaliphatic epoxy/trimethacrylate system. Express Polym Lett 5(2):132–141. doi:10.3144/expresspolymlett.2011.14

Ishida H, Rimdusit S (1998) Very high thermal conductivity obtained by boron nitride-filled polybenzoxazine. Thermochim Acta 320(1–2):177–186. doi:10.1016/S0040-6031(98)00463-8

Yu JH, Huo RM, Wu C, Wu XF, Wang GL, Jiang PK (2012) Influence of interface structure on dielectric properties of epoxy/alumina nanocomposites. Macromol Res 20(8):816–826. doi:10.1007/s13233-012-0122-2

Huang XY, Jiang PK, Tanaka T (2011) A review of dielectric polymer composites with high thermal conductivity. IEEE Electr Insul Mag 27(4):8–16. doi:10.1109/MEI.2011.5954064

Tanimoto M, Yamagata T, Miyata K, Ando S (2013) Anisotropic thermal diffusivity of hexagonal boron nitride-filled polyimide films: effects of filler particle size, aggregation, orientation, and polymer chain rigidity. ACS Appl Mater Inter 5(10):4374–4382. doi:10.1021/am400615z

Yu SZ, Hing P, Hu X (2002) Thermal conductivity of polystyrene–aluminum nitride composite. COMPOS PART A 33(2):289–292. doi:10.1016/S1359-835X(01)00107-5

Reading M, Vaughan AS, Lewin PL (2011) An investigation into improving the breakdown strength and thermal conduction of an epoxy system using boron nitride. In: Annual report conference CEIDP on 16–19 Oct. 2011, pp 636–639. doi:10.1109/CEIDP.2011.6232737

Wang ZB, Iizuka T, Kozako M, Ohki Y, Tanaka T (2011) Development of epoxy/BN composites with high thermal conductivity and sufficient dielectric breakdown strength part II-breakdown strength. IEEE Trans Dielectr Electr Insul 18(6):1973–1983. doi:10.1109/TDEI.2011.6118635

Tanaka T, Kozako M, Okamoto K (2014) Toward High thermal conductivity nano micro epoxy composites with sufficient endurance voltage. ICEE 2(1):90–98. doi:10.5370/jicee.2012.2.1.090

Fang LJ, Wu C, Qian R, Xie LY, Yang K, Jiang PK (2014) Nano–micro structure of functionalized boron nitride and aluminum oxide for epoxy composites with enhanced thermal conductivity and breakdown strength. RSC Adv 4(40):21010–21017. doi:10.1039/c4ra01194e

Yu JH, Huang XY, Wang LC, Peng P, Wu C, Wu XF, Jiang PK (2011) Preparation of hyperbranched aromatic polyamide grafted nanoparticles for thermal properties reinforcement of epoxy composites. Polym Chem-UK 2(6):1380–1388. doi:10.1039/c1py00096a

Li M, Huang XY, Wu C, Xu H, Jiang PK, Tanaka T (2012) Fabrication of two-dimensional hybrid sheets by decorating insulating PANI on reduced graphene oxide for polymer nanocomposites with low dielectric loss and high dielectric constant. J Mater Chem 22(44):23477–23484. doi:10.1039/c2jm34683d

Xie HQ, Wang JC, Xi TG, Liu Y, Ai F, Wu QR (2002) Thermal conductivity enhancement of suspensions containing nanosized alumina particles. J Appl Phys 91(7):4568–4572. doi:10.1063/1.1454184

Hu Y, Du GP, Chen N (2016) A novel approach for Al2O3/epoxy composites with high strength and thermal conductivity. Compos Sci Technol 124:36–43. doi:10.1016/j.compscitech.2016.01.010

Wang YF, Cui J, Yuan QB, Niu YJ, Bai YY, Wang H (2015) Significantly enhanced breakdown strength and energy density in sandwich-structured barium titanate/poly(vinylidene fluoride) nanocomposites. Adv Mater 27(42):6658–6663. doi:10.1002/adma.201503186

Fredin LA, Li Z, Lanagan MT, Ratner MA, Marks TJ (2013) Substantial recoverable energy storage in percolative metallic aluminum-polypropylene nanocomposites. Adv Funct Mater 23(28):3560–3569. doi:10.1002/adfm.201202469

Hu PH, Shen Y, Guan YH, Zhang XH, Lin YH, Zhang QM, Nan C-W (2014) Topological-structure modulated polymer nanocomposites exhibiting highly enhanced dielectric strength and energy density. Adv Funct Mater 24(21):3172–3178. doi:10.1002/adfm.201303684

Hu PH, Wang J, Shen Y, Guan YH, Lin YH, Nan C-W (2013) Highly enhanced energy density induced by hetero-interface in sandwich-structured polymer nanocomposites. J Mater Chem A 1(39):12321–12326. doi:10.1039/c3ta11886j

Zhou SX, Xu JZ, Yang Q-H, Chiang S, Li BH, Du HD, Xu CJ, Kang FY (2013) Experiments and modeling of thermal conductivity of flake graphite/polymer composites affected by adding carbon-based nano-fillers. Carbon 57:452–459. doi:10.1016/j.carbon.2013.02.018

Usowicz B, Lipiec J, Usowicz JB, Marczewski W (2013) Effects of aggregate size on soil thermal conductivity: comparison of measured and model-predicted data. Int J Heat Mass Transf 57(2):536–541. doi:10.1016/j.ijheatmasstransfer.2012.10.067

Zhou YC, Wang H, Xiang F, Zhang H, Yu K, Chen L (2011) A poly(vinylidene fluoride) composite with added self-passivated microaluminum and nanoaluminum particles for enhanced thermal conductivity. Appl Phys Lett 98(18):182906. doi:10.1063/1.3580588

Clancy TC, Gates TS (2006) Modeling of interfacial modification effects on thermal conductivity of carbon nanotube composites. Polymer 47(16):5990–5996. doi:10.1016/j.polymer.2006.05.062

Tsekmes IA, Kochetov R, Morshuis PHF, Smit JJ (2014) A unified model for the permittivity and thermal conductivity of epoxy based composites. J Phys D 47(41):415502. doi:10.1088/0022-3727/47/41/415502

Zhou YC, Yao Y, Chen CY, Moon K, Wang H, Wong CP (2014) The use of polyimide-modified aluminum nitride fillers in AlN@PI/epoxy composites with enhanced thermal conductivity for electronic encapsulation. Sci Rep 4:4779. doi:10.1038/srep04779

Kalaprasad G, Pradeep P, Mathew G, Pavithran C, Thomas S (2000) Thermal conductivity and thermal diffusivity analyses of low-density polyethylene composites reinforced with sisal, glass and intimately mixed sisal/glass fibres. Compos Sci Technol 60(16):2967–2977. doi:10.1016/S0266-3538(00)00162-7

Acknowledgements

The authors thank the colleagues in the laboratory of International Center for Dielectric Research for their support. We thank the Center of Advancing Materials Performance (CAMP-Nano) for providing the SEM, and Dr. Zhaoyang Fan for his help with the SEM operation. This work was financially supported by the National Science Foundation of China (Innovative Research Group, No. 51221005).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interests.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, Z., Cheng, Y., Wang, H. et al. Sandwiched epoxy–alumina composites with synergistically enhanced thermal conductivity and breakdown strength. J Mater Sci 52, 4299–4308 (2017). https://doi.org/10.1007/s10853-016-0511-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0511-6