Abstract

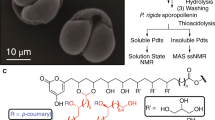

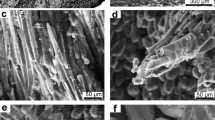

The awned seeds of the family Geraniaceae are special seed-dispersal units. The awns can generate periodic coiling and uncoiling movement through interaction with the diurnal humidity cycle. To investigate how this natural actuator acquires the remarkable property, we determined the three-dimensional morphological features of the coiling awns of Pelargonium peltatum through X-ray microtomography (micro-CT). Many streaks with sharp corners were found distributed in the surface of the inner layer cells, indicating there are two different microfibril angles (MFAs) in the special tilted helix structure of each one cellulose fiber within the cell wall. A simplified mechanical model of the cell wall was developed. Moreover, finite element method was conducted based on the proposed model to analyze the basic mechanism of the coiling deformation. The results showed that stiff cellulose fibers with special tilted helix structures could direct the shrinkage forces resulted from the matrix, so as to generate torsional and bending movement simultaneously. Therefore, the inner layer cell could generate an anti-clockwise coiling deformation macroscopically. In addition, effects of other structural factors including fiber frequency of the cellulose fiber skeletons, modulus ratios between the fibers and matrix, and macroscopical combination among the cells on the degree of the coiling deformation were also studied. The results determined in this work may benefit the development of new kind of intelligent composites.

Similar content being viewed by others

References

Burgert I, Fratzl P (2009) Actuation systems in plants as prototypes for bioinspired devices. Phil Trans R Soc A 367:1541–1557

Dawson C, Vincent JFV, Rocca AM (1997) How pine cones open. Nature 390:668

Reyssat E, Mahadevan L (2009) Hygromorphs: from pine cones to biomimetic bilayers. J R Soc Interface 6:951–957

Ingold CT (1959) Peristome teeth and spore discharge in mosses. Trans Proc Bot Soc 38:76–88

Hegazy AK, Barakat HN, Kabiel HF (2006) Anatomical significance of the hygrochastic movement in Anastatica hierochuntica. Ann Bot-London 97:47–55

Armon S, Efrati E, Kupferman R, Sharon E (2011) Geometry and mechanics in the opening of chiral seed pods. Science 333:1726–1730

Elbaum R, Zaltzman L, Burgert I, Fratzl P (2007) The role of wheat awns in the seed dispersal unit. Science 316:884–886

Elbaum R, Gorb S, Fratzl P (2008) Structures in the cell wall that enable hygroscopic movement of wheat awns. J Struct Biol 164:101–107

Stamp NE (1984) Self-burial behaviour of Erodium cicutarium seeds. J Ecol 72:611–620

Evangelista D, Hotton S, Dumais J (2011) The mechanics of explosive dispersal and self-burial in the seeds of the filaree, Erodium cicutarium (Geraniaceae). J Exp Biol 214:521–529

Abraham Y, Tamburu C, Klein E, Dunlop JWC, Fratzl P, Raviv U, Elbaum R (2012) Tilted cellulose arrangement as a novel mechanism for hygroscopic coiling in the stork’s bill awn. J R Soc Interface 9:640–647

Abraham Y, Elbaum R (2013) Hygroscopic movements in Geraniaceae: the structural variations that are responsible for coiling or bending. New Phytol 199:584–594

Abraham Y, Elbaum R (2013) Quantification of microfibril angle in secondary cell walls at subcellular resolution by means of polarized light microscopy. New Phytol 197:1012–1019

Wonjong J, Wonjung K, Ho-Young K (2014) Self-burial mechanics of hygroscopically responsive awns. Integr Comp Biol 54:1034–1042

Tirrell DA (1994) Hierarchical structures in biology as a guide for new materials technology. National Academy Press, Washington DC

Barnett JR, Bonham VA (2005) Cellulose microfibril angle in the cell wall of wood fibres. Biol Rev 79:461–472

McNeil M, Darvill AG, Fry SC, Albersheim P (1984) Structure and function of the primary cell walls of plants. Ann Rev Biochem 53:625–663

Carpita NC, Gibeaut DM (1993) Structural models of primary cell walls in flowering plants: consistency of molecular structure with the physical properties of the walls during growth. Plant J 3:1–30

Reiter WD (1998) The molecular analysis of cell wall components. Trends Plant Sci 3:27–32

Kerstens S, Decraemer WF, Verbelen JP (2001) Cell walls at the plant surface behave mechanically like fiber-reinforced composite materials. Plant Physiol 127:381–385

Fratzl P, Burgert I, Keckes J (2004) Mechanical model for the deformation of the wood cell wall. Z Metallkd 95:579–584

Burgert I, Fratzl P (2009) Plants control the properties and actuation of their organs through the orientation of cellulose fibrils in their cell walls. Integr Comp Biol 49:69–79

Baskin TI (2005) Anisotropic expansion of the plant cell wall. Annu Rev Cell Dev Bl 21:203–222

Fahn A, Werker E (1972) Seed biology. In: Kozlowski TT (ed) Anatomical mechanisms of seed dispersal. Academic Press, New York, pp 152–221

Lacey EP, Kaufman PB, Dayanandan P (1983) The anatomical basis for hygroscopic movement in primary rays of Daucus carota ssp. carota (Apiaceae). Bot Gaz 144:371–375

Forterre Y, Dumais J (2011) Generating helices in nature. Science 333:1715–1716

Jungnikl K, Goebbels J, Burgert I, Fratzl P (2009) The role of material properties for the mechanical adaptation at branch junctions. Trees 23:605–610

Slater D, Bradley RS, Withers PJ, Ennos AR (2014) The anatomy and grain pattern in forks of hazel (Corylus avellana L.) and other tree species. Trees 28:1437–1448

Kroon-Batenburg LMJ, Kroon J, Norholt MG (1986) Chain modulus and intramolecular hydrogen bonding in native and regenerated cellulose fibers. Polym Commun 27:290–292

Nishino T, Takano K, Nakamae K (1995) Elastic modulus of the crystalline regions of cellulose polymorphs. J Pol Sci Pol Phys 33:1647–1651

Saavedra Floresa EI, de Souza Netob EA, Pearcec C (2011) A large strain computational multi-scale model for the dissipative behavior of wood cell-wall. Comp Mater Sci 50:1202–1211

Hepworth DG, Bruce DM (2000) A method of calculating the mechanical properties of nanoscopic plant cell wall components from tissue properties. J Mater Sci 35:5861–5865

Cousins WJ (1976) Elastic modulus of lignin as related to moisture content. Wood Sci Technol 10:9–17

Cousins WJ (1978) Young’s modulus of hemicellulose as related to moisture content. Wood Sci Technol 12:161–167

Salmén L (2001) Proceedings of 1st International Conference of the European Society for Wood Mechanics. In: Navi P (ed) Micromechanics of the wood cell wall: a tool for the better understanding of its structure. EPFL, Lausanne, pp 385–398

Salmén L (2004) Micromechanical understanding of cell-wall structure. C R Biol 327:873–880

Zamil MS, Yi H, Virendra MP (2015) The mechanical properties of plant cell walls soft material at the subcellular scale: the implications of water and of the intercellular boundaries. J Mater Sci 50:6608–6623

Spatz HC, Köhler L, Niklas KJ (1999) Mechanical behaviour of plant tissues: composite materials or structures? J Exp Biol 202:3269–3272

Yamamoto H, Sassus F, Ninomiya M, Gril J (2001) A model of anisotropic swelling and shrinking process of wood. Wood Sci Technol 35:167–181

Burgert I, Eder M, Gierlinger N, Fratzl P (2007) Tensile and compressive stresses in tracheids are induced by swelling based on geometrical constraints of the wood cell. Planta 226:981–987

Neagu RC, Gamstedt EK (2007) Modeling of effects of ultrastructural morphology on the hygroelastic properties of wood fibers. J Mater Sci 42:10254–10274

Burgert I, Frühmann K, Keckes J, Fratzl P, Stanzl-Tschegg S (2005) Properties of chemically and mechanically isolated fibres of spruce (Picea abies [L.] Karst.). Part 2: twisting phenomena. Holzforschung 59:247–251

Meylan BA, Butterfield BG (1978) Helical orientation of the microfibrils in tracheids, fibres and vessels. Wood Sci Technol 12:219–222

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Zhao, C., Liu, Q., Ren, L. et al. A 3D micromechanical study of hygroscopic coiling deformation in Pelargonium seed: from material and mechanics perspective. J Mater Sci 52, 415–430 (2017). https://doi.org/10.1007/s10853-016-0341-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0341-6