Abstract

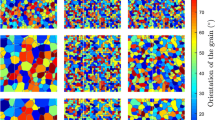

Concurrent evolution of grain size and porosity in solids is a technically important problem involving curvature-driven motion of grain boundaries and the pore motion by surface diffusion. A phase field approach comprising a system of Cahn–Hilliard and Allen–Cahn equations has been developed recently to tackle this problem. Through a formal asymptotic analysis, the current work demonstrates that the phase field model recovers the corresponding sharp-interface dynamics of the co-evolution of grain boundaries and pores; this analysis also fixes the model kinetic parameters in terms of real materials properties. As a case study, the model was used to investigate the effect of porosity on the kinetics of grain growth in CeO2 in 3D. It is shown that the model captures the phenomenon of pore breakaway often observed in experiments. Pores on three- and four-grain junctions were found to move along with the migrating boundary, while edge pores (on the boundary between two grains) were found to easily separate from the boundary. The simulations showed that pore breakaway leads to abnormal grain growth. The simulations also showed that grain growth kinetics in CeO2 changes from boundary controlled to pore controlled as the amount of porosity increases. The kinetic growth parameters such as the growth exponent and the rate constant (or equivalently the activation energy) were found to depend strongly on the precise amount and distribution of porosity, which reconciles the different experimental results reported for grain growth in CeO2.

Similar content being viewed by others

References

Rahaman MN (2003) Ceramic processing and sintering, 2nd edn. Marcel Dekker, New York

Kingery WD, Bowen HK, Uhlmann DR (1976) Introduction to ceramics, 2nd edn. Wiley, New York

Turnbull JA (1974) The effect of grain size on the swelling and gas release properties of UO2 during irradiation. J Nucl Mater 50:62

Olander DR (1976) Fundamental aspects of nuclear reactor fuel element. TID-26711-P1. Technical Information Service, Springfield

Was GS (2007) Fundamentals of radiation materials science-metals and alloys. Springer, Berlin

Ahmed K, Yablinsky CA, Schulte A et al (2013) Phase field modeling of the effect of porosity on grain growth kinetics in polycrystalline ceramics. Model Simul Mater Sci Eng 21:065005

Burke JE, Turnbull D (1952) Recrystallization and grain growth. Prog Metal Phys 3:220

Mullins W (1956) Two-dimensional motion of idealized grain boundaries. J Appl Phys 27:900

Hillert M (1965) On the theory of normal and abnormal grain growth. Acta Metall 13:227

Taylor JE, Cahn JW (1994) Linking anisotropic sharp and diffuse surface motion laws via gradient flows. J Stat Phys 77:183–197

Nichols FA (1968) Further comments on the theory of grain growth in porous compacts. J Am Ceram Soc 51:468

Brook RJ (1969) Pore-grain boundary interactions and grain growth. J Am Ceram Soc 52:56

Carpay FMA (1977) Discontinuous grain growth and pore drag. J Am Ceram Soc 60:82

Hsueh CH, Evans AG, Coble RL (1982) Microstructure development during final/intermediate stage sintering—I. Pore/grain boundary separation. Acta Metall 30:1269

Spears MA, Evans AG (1982) Microstructure development during final/intermediate stage sintering—II. Grain and pore coarsening. Acta Metall 30:1281

Svoboda J, Riedel H (1992) Pore-boundary interactions and evolution equations for the porosity and the grain size during sintering. Acta Metall Mater 40:2829

Riedel H, Svoboda J (1993) A theoretical study of grain growth in porous solids during sintering. Acta Metall Mater 41:1929

Ahmed K, Pakarinen J, Allen T, El-Azab A (2014) Phase field simulation of grain growth in porous uranium dioxide. J Nucl Mater 446:90

Barrett JW, Garcke H, Nurnberg R (2010) Finite-element approximation of coupled surface and grain boundary motion with applications to thermal grooving and sintering. Eur J Appl Math 21:519

Hayun S, Shavareva TY, Navrotsky A (2011) Nanoceria—energetics of surfaces, interfaces and water adsorption. J Am Ceram Soc 94:3992

Mihalache V, Pasuk I (2011) Grain growth, microstructure and surface modification of textured CeO2 thin films on Ni substrate. Acta Mater 59:4875

Mullins W (1956) Theory of thermal grooving. J Appl Phys 28:333

Emmerich H (2008) Advances of and by phase-field modelling in condensed-matter physics. Adv Phys 57:1

Provatas N, Elder K (2010) Phase-field methods in materials science and engineering. Wiley, Weinheim

El-Azab A, Ahmed K, Rokkam S, Hochrainer T (2014) Diffuse interface modeling of void growth in irradiated materials. Mathematical, thermodynamic and atomistic perspectives. Curr Opin Solid State Mater Sci 18:90–98

Fan D, Chen LQ, Chen SP (1998) Numerical simulation of zener pinning with growing second-phase particles. J Am Ceram Soc 81:526

Wang Y (2006) Computer modeling and simulation of solid-state sintering: a phase field approach. Acta Mater 54:953

Chen LQ, Yang W (1994) Computer simulation of the domain dynamics of a quenched system with a large number of nonconserved order parameters: the grain-growth kinetics. Phys Rev B 50:15752

Moelans N, Blanpain B, Wollants P (2008) Quantitative analysis of grain boundary properties in a generalized phase field model for grain growth in anisotropic systems. Phys Rev B 78:024113

Kim SG, Park YB (2008) Grain boundary segregation, solute drag and abnormal grain growth. Acta Mater 56:3739

Cahn JW, Novic-Cohen A (2000) Motion by curvature and impurity drag: resolution of a mobility paradox. Acta Mater 48:3425

Cahn JW, Hilliard JE (1958) Free energy of a nonuniform system. I. Interfacial free energy. J Chem Phys 28:258

De Groot SR, Mazur P (1962) Non-equilibrium thermodynamics. North-Holland Publishing Company, Amesterdam

Cahn JW (1961) On spinodal decomposition. Acta Metall 9:795

Gugenberger C, Spatschek R, Kassner K (2008) Comparison of phase-field models for surface diffusion. Phys Rev E 78:016703

Allen SM, Cahn JW (1979) A microscopic theory for antiphase boundary motion and its application to antiphase domain coarsening. Acta Metall 27:1085

Fife PC (1992) Dynamics of internal layers and diffuse interfaces. SIAM, Philadelphia

Pego RL (1989) Front migration in the nonlinear Cahn–Hilliard equation. Proc Roy Soc London Ser A 422:261

Novic-Cohen A (2000) Triple-junction motion for an Allen–Cahn/Cahn–Hilliard system. Phys D 137:1

Barrett JW, Garcke H, Nurnberg R (2007) A phase field model for the electromigration of intergranular voids. Interfaces Free Bound 9:171–210

Zouvelou N, Mantzouris X, Nikolopoulos P (2008) Surface and grain-boundary energies as well as surface mass transport in polycrystalline CeO2. Mat Sci Eng A 495:54

Chen P, Chen I (1996) Grain growth in CeO2: dopant effects, defect mechanism, and solute drag. J Am Ceram Soc 79:1793

Zhang TS, Hing P, Huang H, Kilner J (2002) Sintering and grain growth of CoO-doped CeO2 ceramics. J Eur Ceram Soc 22:27

Zhang TS, Hing P, Huang H, Kilner J (2002) Sintering study on commercial CeO2 powder with small amount of MnO2 doping. Mater Lett 57:507

Zhang TS, Ma J, Kong LB, Zeng ZQ, Hing P, Kilner J (2003) Final-stage sintering behavior of Fe-doped CeO2. Mat Sci Eng B 103:177

Acknowledgements

This material is based upon work supported as the part of the Center for Materials Science of Nuclear Fuel, an Energy Frontier Research Center funded by the U.S. Department of Energy, Office of Sciences, Office of Basic Energy Sciences under award number FWP 1356, through subcontract number 00122223 at Purdue University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahmed, K., Allen, T. & El-Azab, A. Phase field modeling for grain growth in porous solids. J Mater Sci 51, 1261–1277 (2016). https://doi.org/10.1007/s10853-015-9107-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9107-9