Abstract

The thermodynamics and kinetics fundaments of grain growth in binary substitutional alloys were analyzed using the thermodynamic extremal principle. Applying the regular solution approximation, a new equation for solute segregation at steady-state diffusion is proposed, which suggests reduced solute segregation as the grain boundary (GB) solute concentration increases, differently from previous models [Acta Mater 2009;57(5):1466, Acta Mater 2012;60:4833, Scripta Mater 2010;63:989] that adopt constant segregation enthalpy. Furthermore, a self-consistent consideration has been carried out to account for the coupled changes in GB energy and GB mobility as a result of solute segregation. On this basis, the quantitative relation is evaluated between the thermodynamic and kinetic effects of solute segregation to determine the dominant role in retarding and even suppressing grain growth, by comparison of the dimensionless GB energy (i.e., the GB energy of alloy over that of pure solvent) and the dimensionless effective GB mobility (i.e., the effective GB mobility over that of pure solvent): the kinetic effect prevails if the dimensionless effective GB mobility is smaller than the dimensionless GB energy, and vice versa. The present model is adopted to describe well the experimental results for Fe–P alloys, and nanocrystalline Ni–P and Pd–Zr alloys.

Similar content being viewed by others

Notes

The value of diffusion coefficient of P in the grain boundaries of chemical similar Fe [55] is found within \( s\delta D_{\text{P}}^{\text{GB}} \) = 3.30 × 10−15exp(−92.47 × 103/R g T) at 950–1139 K [s as the segregation factor approximately evaluated by exp(−ΔH seg/R g T)]. The value of s is thus given as 207, the mean of 116–298 utilizing s = exp(−ΔH seg/R g T) with ΔH seg = −45 kJ mol−1 [13] at T = 1139–950 K. Therefore, the value of \( D_{\text{P}}^{\text{GB}} \) is calculated to be 3.5 × 10−16 m2 s−1 at T = 623 K.

References

Krill CE, Ehrhardt H, Birringer R (2005) Thermodynamic stabilization of nanocrystallinity. Z Metallkunde 96:1134–1141

Detor AJ, Miller MK, Schuh CA (2006) Solute distribution in nanocrystalline Ni-W alloys examined through atom probe tomography. Philos Mag 86:4459–4475

Detor AJ, Miller MK, Schuh CA (2007) Measuring grain-boundary segregation in nanocrystalline alloys: direct validation of statistical techniques using atom probe Tomography. Philos Mag Lett 87:581–587

Detor AJ, Schuh CA (2007) Tailoring and patterning the grain size of nanocrystalline alloys. Acta Mater 55:371–379

Darling KA, Chan RN, Wong PZ, Semones JE, Scattergood RO, Koch CC (2008) Grain-size stabilization in nanocrystalline FeZr alloys. Scripta Mater 59:530–533

Koch CC, Scattergood RO, Darling KA, Semones JE (2008) Stabilization of nanocrystalline grain sizes by solute additions. J Mater Sci 43:7264–7272. doi:10.1007/s10853-008-2870-0

Darling KA, VanLeeuwen BK, Semones JE, Koch CC, Scattergood RO, Kecskes LJ, Mathaudhu SN (2011) Stabilized nanocrystalline iron-based alloys: Guiding efforts in alloy selection. Mater Sci Eng A 528:4365–4371

Chen YZ, Herz A, Kirchheim R (2011) Grain boundary segregation of carbon and formation of nanocrystalline iron-carbon alloys by ball milling. Mater Sci Forum 667–669:265–270

Liu F (2005) Precipitation of a metastable Fe(Ag) solid solution upon annealing of supersaturated Fe(Ag) thin film prepared by pulsed laser deposition. Appl Phys A 81:1095–1098

Liu KW, Mücklich F (2001) Thermal stability of nano-RuAl produced by mechanical alloying. Acta Mater 49:395–403

Natter H, Löffler MS, Krill CE, Hempelmann R (2001) Crystallite growth of nanocrystalline transition metals studied in situ by high temperature synchrotron X-ray diffraction. Scripta Mater 44:2321–2325

Weissmüller J (1993) Alloy effects in nanostructures. Nanostruct Mater 3:261–272

Kirchheim R (2002) Grain coarsening inhibited by solute segregation. Acta Mater 50:413–419

Kirchheim R (2007) Reducing grain boundary, dislocation line and vacancy formation energies by solute segregation. I. Acta Mater 55:5129–5138

Kirchheim R (2007) Reducing grain boundary, dislocation line and vacancy formation energies by solute segregation: II. Experimental evidence and consequences. Acta Mater 55:5139–5148

Liu F, Kirchheim R (2004) Nano-scale grain growth inhibited by reducing grain boundary energy through solute segregation. J Cryst Growth 264:385–391

Liu F, Kirchheim R (2004) Grain boundary saturation and grain growth. Scripta Mater 51:521–525

Liu F, Kirchheim R (2004) Comparison between kinetic and thermodynamic effects on grain growth. Thin Solid Films 466:108–113

Trelewicz JR, Schuh CA (2009) Grain boundary segregation and thermodynamically stable binary nanocrystalline alloys. Phys Rev B 79:094112

Detor AJ, Schuh CA (2007) Grain boundary segregation, chemical ordering and stability of nanocrystalline alloys: atomistic computer simulations in the Ni–W system. Acta Mater 55:4221–4232

Millett PC, Selvam RP, Bansal S, Saxena A (2005) Atomistic simulation of grain boundary energetics—effects of dopants. Acta Mater 53:3671–3678

Millett PC, Selvam RP, Saxena A (2006) Molecular dynamics simulations of grain size stabilization in nanocrystalline materials by addition of dopants. Acta Mater 54:297–303

Millett PC, Selvam RP, Saxena A (2007) Stabilizing nanocrystalline materials with dopants. Acta Mater 55:2329–2336

Chookajorn T, Murdoch HA, Schuh CA (2012) Design of stable nanocrystalline alloys. Science 337:951–954

Saber M, Kotan H, Koch C, Scattergood R (2013) Thermodynamic stabilization of nanocrystalline binary alloys. J Appl Phys 113:063515

Saber M, Kotan H, Koch C, Scattergood R (2013) A predictive model for thermodynamic stability of grain size in nanocrystalline ternary alloys. J Appl Phys 114:103510

Cahn JW (1962) The impurity-drag effect in grain boundary motion. Acta Metall 10:789–798

Lücke K, Stüwe HP (1971) On the theory of impurity controlled grain boundary motion. Acta Metall 19:1087–1099

Smith CS (1948) Grains, phases, and interphases: an interpretation of microstructure. Trans AIME 175:15–51

Burke JE (1949) Some factors affecting the rate of grain growth in metals. Trans Metall Soc AIME 175:73

Michels A, Krill CE, Ehrhardt H, Birringer R, Wu DT (1999) Modelling the influence of grain-size-dependent solute drag on the kinetics of grain growth in nanocrystalline materials. Acta Mater 47:2143–2152

Rabkin E (2000) On the grain size dependent solute and particle drag. Scripta Mater 42:1199–1206

Hillert M, Sundman B (1976) A treatment of the solute drag on moving grain boundaries and phase interfaces in binary alloys. Acta Metall 24:731–743

Svoboda J, Fischer FD, Gamsjäger E (2002) Influence of solute segregation and drag on properties of migrating interfaces. Acta Mater 50:967–977

Svoboda J, Fischer FD, Leindl M (2011) Transient solute drag in migrating grain boundaries. Acta Mater 59:6556–6562

Chen Z, Liu F, Wang HF, Yang W, Yang GC, Zhou YH (2009) Acta Mater 57:1466–1475

Chen Z, Liu F, Yang XQ, Shen CJ (2012) A thermokinetic description of nanoscale grain growth: analysis of the activation energy effect. Acta Mater 60:4833–4844

Gong MM, Liu F, Zhang K (2010) A thermokinetic description of nanoscale grain growth: analysis of initial grain boundary excess amount. Scripta Mater 63:989–992

Hillert M (2007) Phase equilibria, phase diagrams and phase transformations: their thermodynamic basis, 2nd edn. Cambridge University Press, New York

Svoboda J, Turek I, Fischer FD (2005) Application of the thermodynamic extremal principle to modeling of thermodynamic processes in material sciences. Philos Mag 85:3699–3707

Wang H, Liu F, Yang W, Chen Z, Yang G, Zhou Y (2008) Solute trapping model incorporating diffusive interface. Acta Mater 56:746–753

Hillert M (1965) On the theory of normal and abnormal grain growth. Acta Metall 13:227–238

Burke J, Turnbull D (1952) Recrystallization and grain growth. Prog Metal Phys 3:220

Plessis JD (1990) Surface Segregation. Trans Tech Pubn, Switzerland

Mclean D (1957) Grain boundaries in metals. Oxford University Press, Oxford

Lejček P, Hofmann S, Janovec J (2007) Prediction of enthalpy and entropy of solute segregation at individual grain boundaries of α-iron and ferrite steels. Mater Sci Eng A 462:76–85

Nishizawa T (2008) Thermodynamics of Microstructures. ASM International, OH

Hondros ED (1965) The influence of phosphorus in dilute solid solution on the absolute surface and grain boundary energies of iron. Proc R Soc 286:479–498

Takeuchi A, Inoue A (2000) Calculations of mixing enthalpy and mismatch entropy for ternary amorphous alloys. Mater Trans JIM 41:1372–1378

Färber B, Cadel E, Menand A, Schmitz G, Kirchheim R (2000) Phosphorus segregation in nanocrystalline Ni–3.6 at.% P alloy investigated with the tomographic atom probe (TAP). Acta Mater 48:789–796

Fowler RH, Guggenheim EA (1939) Statistical thermodynamics. Cambridge University Press, Cambridge

Vitos L, Ruban AV, Skriver HL, Kollár J (1998) The surface energy of metals. Surf Sci 411:186–202

Osmola D, Nolan P, Erb U, Palumbo G, Aust KT (1992) Microstructural evolution at large driving forces during grain growth of ultrafine-grained Ni-1.2wt% P. Phys Stat Sol A 131:569–575

Mishin Y, Herzig C, Bernardini J, Gust W (1997) Grain boundary diffusion: fundamentals to recent developments. Int Mater Rev 42:155–178

Mehrer H (1990) Diffusion in solid metals and alloys. Springer, Berlin

VanLeeuwen BK, Darling KA, Koch CC, Scattergood RO, Butler BG (2010) Thermal stability of nanocrystalline Pd81Zr19. Acta Mater 58:4292–4297

Acknowledgements

The authors are grateful to the financial support of National Basic Research Program of China (No. 2011CB610403), the Natural Science Foundation of China (Nos. 51134011 and 51431008), the Fundamental Research Fund of Northwestern Polytechnical University (No. JC20120223), and the China National Funds for Distinguished Young Scientists (No. 51125002). M.M. Gong is thanked for the financial support of the Doctorate Foundation of Northwestern Polytechnical University (CX201204). R. H. R. Castro is thanked for the financial support of the National Science Foundation (DMR 1055504).

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1

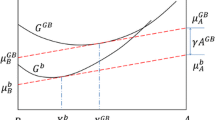

In Hillert’s derivation [39, 47], as the equilibrium state is corresponding to the minimum of total Gibbs energy in the system, the change of total Gibbs energy must remain zero when tiny solvent atoms with amount of dn A and solute atoms with amount of dn B are transferred from the bulk phase to the GB one, i.e., [47]

In general, the solution of Eq. (32) is \( \mu_{\text{A}}^{\text{GB}} = \mu_{\text{A}}^{\text{bulk}} \) and \( \mu_{\text{B}}^{\text{GB}} - \mu_{\text{B}}^{\text{bulk}} \) due to the arbitrary dn A and dn B. However, under the assumption of constant GB width yielding dn A + dn B = 0, the precondition of Eq. (32) is \( \mu_{\text{B}}^{\text{GB}} - \mu_{\text{B}}^{\text{bulk}} \) = \( \mu_{\text{B}}^{\text{GB}} - \mu_{\text{B}}^{\text{bulk}} \) identical to Eq. (15). That is to say, the steady-state diffusion of components implies the equilibrium between the bulk and GB phases.

Appendix 2

The change of total Gibbs free energy in the system can be given by,

According to Gibbs–Duhem relation, Eq. (33) is rewritten as,

Then, with mass conservation equations dn GBA + dn bulkA = 0 and dn GBB + dn bulkB = 0, the last equation is further simplified as,

Thereafter, combining Eq. (35) with Eq. (15) yields

With \( {\text{d}}n^{\text{GB}} \) = δdS/V m, Eq. (36) is changed into

Further incorporating Eq. (18) into Eq. (37) leads to

On this basis, the driving force P of grain growth can be presented according to its definition (i.e., P = dG/dV) as,

By means of S = 4πR 2/2 (1/2 implying a GB shared by two adjacent grains) and V = 4/3πR 3, Eq. (39) is thus simplified as,

Definitely, under steady-state diffusion, the GB energy can be regarded as the driving force of the grain growth affected by solute segregation.

Rights and permissions

About this article

Cite this article

Gong, M.M., Castro, R.H.R. & Liu, F. Modeling grain growth kinetics of binary substitutional alloys by the thermodynamic extremal principle. J Mater Sci 50, 4610–4621 (2015). https://doi.org/10.1007/s10853-015-9010-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9010-4