Abstract

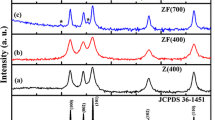

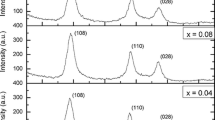

Nanograined (grain size 6–15 nm) ZnO films with various Fe content (between 0 and 40 at.%) were synthesized by the novel liquid ceramics method. The films with 0, 0.1, 5 and 10 at.% Fe contain only ZnO-based solid solution with wurtzite structure. The films with 20 at.% Fe contain mainly amorphous phase. The peaks of the second phase (ZnFe2O4 with cubic lattice) become visible in the X-ray diffraction spectra at 30 at.% Fe. Therefore, the overall solubility of Fe in nanograined ZnO films at 550 °C is about 20 at.% Fe. The solubility limit in the bulk is about 1.5 at.% Fe. The recently published papers on the structure and magnetic behaviour of Fe-doped ZnO allowed us to obtain the dependence of Fe solubility in ZnO on the grain size. The overall Fe solubility drastically increases with the decreasing grain size. The quantitative estimation shows that, close to the bulk solubility limit, the thickness of a Fe-enriched layer in grain boundaries is that of several monolayers.

Similar content being viewed by others

References

McLean D (1957) Grain boundaries in metals. Clarendon Press, Oxford

Beke DL, Cserháti C, Erdélyi Z, Szabó IA (2002) Segregation in nanostructures. In: Nalwa HS (ed) Nanoclusters and nanocrystals. American Scientific Publishers, Valencia

Beke DL, Erdélyi Z, Bakos P, Cserháti C, Szabó IA (1999) Segregation induced phase transformations in nanostructures. In: Koiwa M, Otsuka K, Miyazaki T (eds) Proceedings of the international conference solid–solid phase transformations’99 (JIMIC-3). The Japan Inst. Met., Tokyo

Weissmuller J, Chr L (2000) On the size dependence of the critical point of nanoscale interstitial solid solutions. Philos Mag Lett 80:411–418

Lartigue-Korinek S, Legros C, Carry C, Herbst F (2006) Titanium effect on phase transformation and sintering behavior of transition alumina. J Eur Ceram Soc 26:2219–2230

Gülgün MA, Voytovych R, Maclaren I, Rühle M, Cannon RM (2002) Cation segregation in an oxide ceramic with low solubility: yttrium doped alpha-alumina. Interface Sci 10:99–110

Wang Q, Lian G, Dickey EC (2004) Grain boundary segregation in yttrium-doped polycrystalline TiO2. Acta Mater 52:809–820

Terwilliger CD, Chiang YM (1995) Size-dependent solute segregation and total solubility in ultrafine polycrystals: Ca in TiO2. Acta Metall Mater 43:319–328

Dietl T, Ohno H, Matsukura F, Cibert J, Ferrand D (2000) Zener model description of ferromagnetism in zinc-blended magnetic semiconductors. Science 287:1019–1022

Dietl T (2010) A ten-year perspective on dilute magnetic semiconductors and oxides. Nat Mater 9:965–974

Sato K, Katayama-Yoshida H (2002) First principles materials design for semiconductor spintronics. Semicond Sci Technol 17:367–376

Cheng FF, Ding BF, Pan F, Yao SD, Potzger K, Zhou SQ (2012) Investigation on the structural and magnetic properties of Co+ implanted rutile TiO2. Nucl Instrum Methods Phys Res B 286:180–183

Prucnal S, Shalimov A, Ozerov M, Potzger K, Skorupa W (2012) Magnetic and optical properties of virgin arc furnace grown MgO crystals. J Cryst Growth 339:70–74

Potzger K (2012) Ion-beam synthesis of magnetic semiconductors. Nucl Instrum Methods Phys Res B 272:78–87

Ding BF, Cheng FF, Pan F, Fa T, Yao S, Potzger K, Zhou SQ (2012) The correlation between structure and magnetism of Ni-implanted TiO2 annealed at different temperatures. J Magn Magn Mater 324:33–36

Soyer A (1993) LMCTEP: software for crystal-structure representation. J Appl Crystallogr 26:495

Straumal BB, Mazilkin AA, Protasova SG, Straumal PB, Myatiev AA, Schütz G, Goering E, Tietze Th, Baretzky B (2013) Grain boundaries as the controlling factor for the ferromagnetic behaviour of Co-doped ZnO. Philos Mag 93:1371–1383

König U, Chol G (1968) Röntgenbeugungs- und Neutronenbeugungsuntersuchungen an Ferriten der reihe MnxZn1−xFe2O4. J Appl Crystallogr 1:124–128

Zhou S, Potzger K, Reuther H, Talut G, Eichhorn F, von Borany J, Skorupa W, Helm M, Fassbender J (2007) Crystallographically oriented magnetic ZnFe2O4 nanoparticles synthesized by Fe implantation into ZnO. J Phys D 40:964–969

Bates CH, White WB, Roy R (1966) The solubility of transition metal oxides in zinc oxide and the reflectance spectra of Mn2+ and Fe2+ in tetrahedral fields. J Inorg Nucl Chem 28:397–405

Straumal BB, Protasova SG, Mazilkin AA, Straumal PB, Schütz G, Tietze Th, Goering E, Baretzky B (2013) Ferromagnetic behaviour of Fe-doped ZnO nanograined films. Beilstein J Nanotechnol 4:361–369

Straumal BB, Protasova SG, Mazilkin AA, Schütz G, Goering E, Baretzky B, Straumal PB (2013) Ferromagnetism of zinc oxide nanograined films. JETP Lett 97:367–377

Zhou S, Potzger K, Reuther H, Talut G, von Borany J, Skorupa W, Helm M, Fassbender J (2008) Using X-ray diffraction to identify precipitates in transition metal doped semiconductors. J Appl Phys 103:07D530

Zhang H-W, Wei Z-R, Li Z-Q, Dong G-Y (2007) Room-temperature ferromagnetism in Fe-doped, Fe- and Cu-codoped ZnO diluted magnetic semiconductor. Mater Lett 61:3605–3607

Kolesnik S, Dabrowski B, Mais J (2004) Structural and magnetic properties of transition metal substituted ZnO. J Appl Phys 95:2582–2586

Shim JH, Hwang T, Lee S, Park JH, Han S-J, Jeong JH (2005) Origin of ferromagnetism in Fe- and Cu-codoped ZnO. Appl Phys Lett 86:082503

Blasco J, Bartolomé F, García LM, García J (2006) Extrinsic origin of ferromagnetism in doped ZnO. J Mater Chem 16:2282–2288

Han S-J, Song JW, Yang C-H, Park SH, Park J-H, Jeong YH, Rhie KW (2002) A key to room-temperature ferromagnetism in Fe-doped ZnO:Cu. Appl Phys Lett 81:4212–4214

Blasco J, Bartolomé F, García LM, García J (2007) Magnetic properties of doped ZnO prepared by different synthetic routes. J Magn Magn Mater 316:e177–e180

Jayakumar OD, Gopalakrishnan IK, Kulshreshtha SK (2006) Magnetization study of Fe-doped ZnO co-doped with Cu: synthesized by wet chemical method. J Mater Sci 41:4706–4712. doi:10.1007/s10853-006-0045-4

Ahn GY, Park S-I, Shim I-B, Kim CS (2004) Mössbauer studies of ferromagnetism in Fe-doped ZnO magnetic semiconductor. J Magn Magn Mater 282:166–169

Tamura T, Ozaki H (2009) The relationship of the magnetic properties of M (M = Mn, Fe, Co)-doped ZnO single crystals and their electronic structures. J Phys Condens Matter 21:026009

Zhou S, Potzger K, Talut G, Reuther H, von Borany J, Grötzschel R, Skorupa W, Helm M, Fassbender J (2008) Fe-implanted ZnO: magnetic precipitates versus dilution. J Appl Phys 103:023902

Weyer G, Gunnlaugsson HP, Mantovan R, Fanciulli M, Naidoo D, Bharuth-Ram K, Agne T (2007) Defect-related local magnetism at dilute Fe atoms in ion-implanted ZnO. J Appl Phys 102:113915

Polyakov AY, Govorkov AV, Smirnov NB, Pashkova NV, Pearton SJ, Ip K, Frazier RM, Abernathy CR, Norton DP, Zavada JM, Wilson RG (2004) Optical and magnetic properties of ZnO bulk crystals implanted with Cr and Fe. Mater Sci Semicond Proc 7:77–81

Wang D, Chen ZQ, Zhou F, Lu W, Maekawa M, Kawasuso A (2009) Ferromagnetism and microstructure in Fe+-implanted ZnO. Appl Surf Sci 255:9371–9375

Schumm M, Koerdel M, Müller S, Ronning C, Dynowska E, Gołacki Z, Szuszkiewicz W, Geurts J (2009) Secondary phase segregation in heavily transition metal implanted ZnO. J Appl Phys 105:083525

Zhou S, Potzger K, Xu Q, Talut G, Lorenz M, Skorupa W, Helm M, Fassbender J, Grundmann M, Schmidt H (2009) Ferromagnetic transition metal implanted ZnO: a diluted magnetic semiconductor? Vacuum 83:S13–S19

Wu P, Saraf G, Lu Y, Hill DH, Gateau R, Wielunski L, Bartynski RA, Arena DA, Dvorak J, Moodenbaugh A, Siegrist T, Raley JA, Yeo YK (2006) Ferromagnetism in Fe-implanted a-plane ZnO films. Appl Phys Lett 89:012508

Potzger K, Zhou S, Reuther H, Mücklich A, Eichhorn F, Schell N, Skorupa W, Helm M, Fassbender J, Herrmannsdörfer T, Papageorgiou TP (2006) Fe implanted ferromagnetic ZnO. Appl Phys Lett 88:052508

Rita E, Wahl U, Correia JG, Alves E, Soares JC (2004) Lattice location and thermal stability of implanted Fe in ZnO. Appl Phys Lett 85:4899–4901

Karamat S, Ke C, Tan TL, Zhou W, Lee P, Rawat RS (2009) Investigation of impurity phase formation for ZnO1−xTMOx bulk samples formed by ball milling. Appl Surf Sci 255:4814–4820

Chen J, Liu J, West A, Yan Y, Yu M, Zhou W (2008) Room temperature ferromagnetism of FeCo-codoped ZnO nanorods prepared by chemical vapor deposition. IEEE Trans Magn 44:2681–2683

Shinagawa T, Izaki M, Inui H, Murase K, Awakura Y (2006) Microstructures and MR effects of transparent ferromagnetic chemically prepared Fe–Zn–O films. Phys Stat Sol A 203:2760–2764

Liu H, Yang J, Zhang Y, Wang Y, Wei M (2008) Ferromagnetism and exchange bias in Fe-doped ZnO nanocrystals. Mater Chem Phys 112:1021–1023

Zhang B, Li QH, Shi LQ, Cheng HS, Wang JZ (2008) Room temperature ferromagnetism of Fe-implanted ZnO film. J Vac Sci Technol A 26:1469–1473

Zhang Y, Wu L, Li H, Xu J, Han L, Wang B, Tuo Z, Xie E (2009) Influence of Fe doping on the optical property of ZnO films. J Alloys Compd 473:319–322

Liu H, Yang J, Zhang Y, Yang L, Wei M, Ding X (2009) Structure and magnetic properties of Fe-doped ZnO prepared by the sol–gel method. J Phys Condens Matter 21:145803

Yoon SW, Cho S-B, We SC, Yoon S, Suh BJ, Song HK, Shin YJ (2003) Magnetic properties of ZnO-based diluted magnetic semiconductors. J Appl Phys 93:7879–7881

Glaspell G, Dutta P, Manivannan A (2005) A room-temperature and microwave synthesis of M-doped ZnO (M = Co, Cr, Fe, Mn & Ni). J Cluster Sci 16:523–536

Fernandes DM, Winkler Hechenleitner AA, Silva MF, Lima MK, Stival Bittencourt PR, Silva R, Custydio Melo MA, Gymez Pineda EA (2009) Preparation and characterization of NiO, Fe2O3, Ni0.04Zn0.96O and Fe0.03Zn0.97O nanoparticles. Mater Chem Phys 118:447–452

Cho YM, Choo WK, Kim H, Kim D, Ihm YE (2002) Effects of rapid thermal annealing on the ferromagnetic properties of sputtered Zn1−x(Co0.5Fe0.5)xO thin films. Appl Phys Lett 80:3358–3360

Seo SY, Kwak CH, Lee YB, Kim SH, Park SH, Han SW (2008) Structural and magnetic properties of Zn1−xFexO thin films synthesized by RF magnetron sputtering. J Korean Phys Soc 52:805–809

Seo SY, Kwak CH, Lee YB, Kim SH, Park SH, Han SW (2008) Hole-induced ferromagnetic properties of Fe-added ZnO films. J Korean Phys Soc 52:249–252

Chen AJ, Wu XM, Sha ZD, Zhuge LJ, Meng YD (2006) Structure and photoluminescence properties of Fe-doped ZnO thin films. J Phys D 39:4762–4765

Wang C, Chen Z, He Y, Li L, Zhang D (2009) Structure, morphology and properties of Fe-doped ZnO films prepared by facing-target magnetron sputtering system. Appl Surf Sci 255:6881–6887

Zhao RB, Hou DL, Wei YY, Zhou ZZ, Pan CF, Zhen CM, Tang GD (2009) Ferromagnetism in Fe-doped ZnO thin films. Mod Phys Lett B 23:815–824

Dorneles LS, O’Mahony D, Fitzgerald CB, McGee F, Venkatesan M, Stanca I, Lunney JG, Coey JMD (2005) Structural and compositional analysis of transition-metal-doped ZnO and GaNPLD thin films. Appl Surf Sci 248:406–410

Venkatesan M, Fitzgerald CB, Lunney JG, Coey JMD (2004) Anisotropic ferromagnetism in substituted zinc oxide. Phys Rev Lett 93:177206

Hong NH, Sakai J, Brizé V (2007) Observation of ferromagnetism at room temperature in ZnO thin films. J Phys Condens Matter 19:036219

Feng QJ, Shen DZ, Zhang JY, Li BH, Zhang ZZ, Lu YM, Fan XW (2008) Room temperature ferromagnetic properties of ZnFeO thin films prepared by thermal oxidation of ZnFeS thin films. Mater Mater Chem Phys 112:1106–1109

Kumar R, Pratap Singh A, Thakur P, Chae KH, Choi WK, Angadi B, Kaushik SD, Patnaik S (2008) Ferromagnetism and metal-semiconducting transition in Fe-doped ZnO thin films. J Phys D Appl Phys 41:155002

Mandal SK, Nath TK, Karmakar D (2008) Magnetic and optical properties of Zn1−xFexO (x = 0.05 and 0.10) diluted magnetic semiconducting nanoparticles Philos Mag 88:265–275

Kataoka T, Kobayashi M, Song GS, Sakamoto Y, Fujimori A, Chang FH, Lin HJ, Huang DJ, Chen CT, Mandal SK, Nath TK, Karmakar D, Dasgupta I (2009) X-ray magnetic circular dichroism investigations of the origin of room temperature ferromagnetism in Fe-doped ZnO nanoparticles. Jpn J Appl Phys 48:04C200

Karmakar D, Mandal SK, Kadam RM, Paulose PL, Rajarajan AK, Nath TK, Das AK, Dasgupta I, Das GP (2007) Ferromagnetism in Fe-doped ZnO nanocrystals: experiment and theory. Phys Rev B 75:144404

Kimishima Y, Uehara M, Irie K, Ishihara S, Yamaguchi Y, Saitoh TM, Kimoto K, Matsui Y (2008) Production of bulk dilute ferromagnetic semiconductor by mechanical milling. J Magn Magn Mater 320:e674–e677

Lin Y, Jiang D, Lin F, Shi W, Ma X (2007) Fe-doped ZnO magnetic semiconductor by mechanical alloying. J Alloys Compd 436:30–33

Xin M, Chen Y, Jia C, Zhang X (2008) Electro-codeposition synthesis and room temperature ferromagnetic anisotropy of high concentration Fe-doped ZnO nanowire arrays. Mater Lett 62:2717–2720

Uum YR, Han BS, Lee HM, Hong SM, Kim GM, Rhee CK (2007) Magnetic and photocatalytic effect of Fe-doped nano-rod ZnO synthesized by the hydrolysis of metal powders. Phys Stat Sol C 4:4408–4411

Alaria J, Venkatesan M, Coey JMD (2008) Magnetism of ZnO nanoparticles doped with 3d cations prepared by a solvothermal method. J Appl Phys 103:07D123

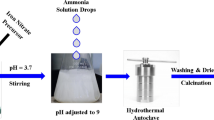

Rattana T, Suwanboon S, Amornpitoksuk P, Haidoux A, Limsuwan P (2009) Improvement of optical properties of nanocrystalline Fe-doped ZnO powders through precipitation method from citrate-modified zinc nitrate solution. J Alloys Compd 480:603–607

Sharma PK, Dutta RK, Pandey AC, Layek S, Verma HC (2009) Effect of iron doping concentration on magnetic properties of ZnO nanoparticles. J Magn Magn Mater 321:2587–2591

Hosford WF (2007) Materials science: an intermediate text. Cambridge University Press, Cambridge

Clarke DR (1987) On the equilibrium thickness of intergranular glass phases in ceramic materials. J Am Ceram Soc 70:15–22

Clarke DR, Shaw TM, Philipse AP, Horn RG (1993) Possible electrical double-layer contribution to the equilibrium thickness of intergranular glass-films in polycrystalline ceramics. J Am Ceram Soc 76:1201–1204

Tanaka I, Kleebe HJ, Cinibulk MK, Bruley J, Clarke DR, Rühle MJ (1994) Calcium concentration dependence of the intergranular film thickness in silicon. Am Ceram Soc 77:911–914

Bobeth M, Clarke DR, Pompe W (1999) A diffuse interface description of intergranular films in polycrystalline ceramics. J Am Ceram Soc 82:1537–1546

Avishai A, Scheu C, Kaplan WD (2005) Intergranular films at metal–ceramic interfaces Part I—interface structure and chemistry. Acta Mater 53:1559–1569

Levi G, Kaplan WD (2006) The influence of interfacial wetting and adhesion on the formation of voids at metal-ceramic interfaces. J Mater Sci 41:817–821. doi:10.1007/s10853-006-6565-0

Baram M, Kaplan WD (2006) Intergranular films at Au-sapphire interfaces. J Mater Sci 41:7775–7784. doi:10.1007/s10853-006-0897-7

Lee JR, Chiang YM, Ceder G (1997) Pressure-thermodynamic study of grain boundaries: Bi segregation in ZnO. Acta Mater 45:1247–1257

Wang H, Chiang YM (1998) Thermodynamic stability of intergranular amorphous films in bismuth-doped zinc oxide. J Am Ceram Soc 81:89–96

Kleebe HJ, Hoffmann MJ, Rühle M (1992) Influence of secondary phase chemistry on grain boundary film thickness in silicon nitride. Z Metallkd 83:610–617

Kleebe HJ, Cinibulk MK, Cannon RM, Rühle M (1993) Statistical analysis of the intergranular film thickness in silicon nitride ceramics. J Am Ceram Soc 76:1969–1977

Chiang YM, Silverman LA, French RH, Cannon RM (1994) Thin glass film between ultrafine conductor particles in thick-film resistors. J Am Ceram Soc 77:1143–1152

Ackler HD, Chiang YM (1997) Model experiment on thermodynamic stability of retained intergranular amorphous films. J Am Ceram Soc 80:1893–1896

Chiang YM, Wang H, Lee JR (1998) HREM and STEM of intergranular films at zinc oxide varistor grain boundaries. J Microsc 191:275–285

Ackler HD, Chiang YM (1999) Effect of initial microstructure on final intergranular phase distribution in liquid-phase-sintered ceramics. J Am Ceram Soc 82:183–189

Cannon RM, Esposito L (1999) High temperature colloidal behavior: particles in liquid silicates. Z Metallkd 90:1002–1015

Luo J, Wang H, Chiang YM (1999) Origin of solid-state activated sintering in Bi2O3-doped ZnO. J Am Ceram Soc 82:916–920

Cahn JW (1977) Critical point wetting. J Chem Phys 66:3667–3672

Eustathopoulos N (1983) Energetics of solid/liquid interfaces of metals and alloys. Int Met Rev 28:189–210

Straumal BB, Gust W, Watanabe T (1999) Tie lines of the grain boundary wetting phase transition in the Zn-rich part of the Zn–Sn phase diagram. Mater Sci Forum 294(296):411–414

Semenov VN, Straumal BB, Glebovsky VG, Gust W (1995) Preparation of Fe–Si single crystals and bicrystals for diffusion experiments by the electron-beam floating zone technique. J Cryst Growth 151:180–186

Straumal B, Rabkin E, Lojkowski W, Gust W, Shvindlerman LS (1997) Pressure influence on the grain boundary wetting phase transition in Fe–Si alloys. Acta Mater 45:1931–1940

Straumal BB, Mazilkin AA, Kogtenkova OA, Protasova SG, Baretzky B (2007) Grain boundary phase observed in Al-5 at.% Zn alloy by using HREM. Philos Mag Lett 87:423–430

Straumal BB, Kogtenkova O, Zięba P (2008) Wetting transition of grain-boundary triple junctions. Acta Mater 56:925–933

Gupta VK, Yoon DH, Meyer HM III, Luo J (2007) Thin intergranular films and solid-state activated sintering in nickel-doped tungsten. Acta Mater 55:3131–3142

Luo J, Gupta VK, Yoon DH, Meyer HM (2005) Segregation-induced grain boundary premelting in nickel-doped tungsten. Appl Phys Lett 87:231902

Tang M, Carter WC, Cannon RM (2006) Grain boundary transitions in binary alloys. Phys Rev Lett 97:075502

Tang M, Carter WC, Cannon RM (2006) Diffuse interface model for structural transitions of grain boundaries. Phys Rev B 73:024102

Luo J, Tang M, Cannon RM, Carter WC, Chiang YM (2006) Pressure-balance and diffuse-interface models for surficial amorphous films. Mater Sci Eng A 422:19–28

Kaplan WD, Chatain D, Wynblatt P, Carter WC (2013) A review of wetting versus adsorption, complexions, and related phenomena: the rosetta stone of wetting. J Mater Sci 48:5681–5717. doi:10.1007/s10853-013-7462-y

Luo J (2007) Stabilization of nanoscale quasi-liquid interfacial films in inorganic materials: a review and critical assessment. Crit Rev Solid State Mater Sci 32:67–109

Luo J, Chiang YM, Cannon RM (2005) Nanometer-thick surficial films in oxides as a case of prewetting. Langmuir 21:7358–7365

Wong J (1974) Nature of intergranular phase in nonohmic ZnO ceramics containing 9.5 mol percent Bi2O3. J Am Ceram Soc 57:357–359

Wong J, Morris WG (1974) Microstruture and phases in nonohmic ZnO–Bi2O3 ceramics. Am Ceram Soc Bull 53:816–820

Greuter F (1995) Electrically active interfaces in ZnO varistors. Sol State Ionics 75:67–78

Gambino JP, Kingery WD, Pike GE, Philipp HR (1989) Effect of heat-treatments on the wetting behaviour of bismuth-rich intergarnular phases in ZnO–Bi–Co varistors. J Am Ceram Soc 72:642–645

Kingery WD, van der Sande JB, Mitamura T (1979) STEM investigation of grain boundary segregation in a ZnO–Bi2O3 varistor. J Am Ceram Soc 62:221–222

Olsson E, Falk LKL, Dunlop GL (1985) The microstructure of a ZnO varistor material. J Mater Sci 20:4091–4098. doi:10.1007/BF00552403

Olsson E, Dunlop GL (1989) Characterization of individual interfacial barriers in a ZnO varistor material. J Appl Phys 66:3666–3675

Matsuoka M (1971) Nonohmic properties of zinc oxide ceramics. Jpn J Appl Phys 10:736–742

Luo J, Chiang YM (2008) Wetting and prewetting on ceramic surfaces. Annu Rev Mater Res 38:227–249

Luo J, Chiang YM (2000) Existence and stability of nanometer-thick disordered films on oxide surfaces. Acta Mater 48:4501–4515

Qian H, Luo J (2007) Vanadia-based equilibrium-thickness amorphous films on anatase (101) surfaces. J Appl Phys Lett 91:061909

Qian H, Luo J, Chiang YM (2008) Anisotropic wetting of ZnO by Bi2O3 with and without nanometer-thick surficial amorphous films. Acta Mater 56:862–873

Acknowledgements

This work was partially supported by the Russian Foundation for Basic Research (grants: 10-02-00086, 11-03-01198, 11-03-00029 and 12-08-31185), by the Ministry of Education and Science of the Russian Federation (contract 14.B25.31.0018), and by Karlsruhe Nano Micro Facility.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Protasova, S.G., Straumal, B.B., Mazilkin, A.A. et al. Increase of Fe solubility in ZnO induced by the grain boundary adsorption. J Mater Sci 49, 4490–4498 (2014). https://doi.org/10.1007/s10853-014-8146-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8146-y