Abstract

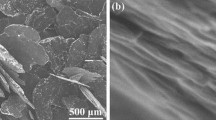

Mass graphene sheets were obtained by a re-expansion and exfoliation method which uses the commercially available graphite intercalation compounds as the starting materials. The as-prepared samples have been characterized by scanning electronic microscopy, transmission electron microscope, atomic force microscope, Fourier transform infrared spectrometer spectroscopies, and Raman microscope. Using high resolution transmission electron microscopy on 60 samples, it was shown that the final samples exhibit 8 % monolayer, 19 % bilayer, and 77 % less than or equal to five layers, and the sheets are largely free of defects and chemical functional groups after thermal reduction.

Similar content being viewed by others

References

Novoselov KS, Geim AK, Morozov SV et al (2004) Electric field effect in atomically thin carbon films. Science 306:666–669

Nguyen ST, Stankovich S, Dikin DA et al (2006) Graphene-based composite materials. Nature 442:282–286

Shin MK, Lee B, Kim SH et al (2012) Synergistic toughening of composite fibres by self-alignment of reduced graphene oxide and carbon nanotubes. Nat Commun 3:1–8

Liu CB, Wang K, Luo SL, Tang YH, Chen LY (2011) Direct electrodeposition of graphene enabling the one-step synthesis of graphene–metal nanocomposite films. Small 7:1203–1206

Dong XC, Xu H, Wang XW et al (2012) 3D graphene–cobalt oxide electrode for high-performance supercapacitor and enzymeless glucose detection. ACS Nano 6:3206–3213

Stoller MD, Park SJ, Zhu YW, An JH, Ruoff RS (2008) Graphene-based ultracapacitors. Nano Lett 8:3498–3502

Zhu YW, Murali S, Stoller MD et al (2011) Carbon-based supercapacitors produced by activation of graphene. Science 332:1537–1541

El-Kady MF, Strong V, Dubin S, Kaner RB (2012) Laser scribing of high-performance and flexible graphene-based electrochemical capacitors. Science 335:1326–1330

Tsen AW, Brown L, Levendorf MP et al (2012) Tailoring electrical transport across grain boundaries in polycrystalline graphene. Science 336:1143–1146

Guo SR, Ghazinejad M, Qin XD et al (2012) Tuning electron transport in graphene-based field-effect devices using block co-polymers. Small 8:1073–1080

Booth TJ, Blake P, Nair RR et al (2008) Macroscopic graphene membranes and their extraordinary stiffness. Nano Lett 8:2442–2446

Lee C, Wei XD, Kysar JW, Hone J (2008) Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321:385–388

Klemens PG (2000) Theory of the a-plane thermal conductivity of graphite. J Wide Bandgap Mater 7:332–339

Balandin AA, Ghosh S, Bao WZ et al (2008) Superior thermal conductivity of single-layer graphene. Nano Lett 8:902–907

Chen SS, Wu QZ, Mishra C et al (2012) Thermal conductivity of isotopically modified graphene. Nat Mater 11:203–207

Alekseev A, Chen DL, Tkalya EE et al (2012) Local organization of graphene network inside graphene/polymer composites. Adv Funct Mater 22:1311–1318

Yavari F, Fard HR, Pashayi K et al (2011) Enhanced thermal conductivity in a nanostructured phase change composite due to low concentration graphene additives. J Phys Chem C 115:8753–8758

Shahil KMF, Balandin AA (2012) Graphene-multilayer graphene nanocomposites as highly efficient thermal interface materials. Nano Lett 12:861–867

Prasai D, Tuberquia JC, Harl RR, Jennings GK, Bolotin KI (2012) Graphene: corrosion-inhibiting coating. ACS Nano 6:1102–1108

Raman RKS, Banerjee PC, Lobo DE et al (2012) Protecting copper from electrochemical degradation by graphene coating. Carbon 50:4040–4045

Yoo E, Kim J, Hosono E, Zhou H, Kudo T, Honma I (2008) Large reversible Li storage of graphene nanosheet families for use in rechargeable lithium ion batteries. Nano Lett 8:2277–2282

Su FY, You CH, He YB et al (2010) Flexible and planar graphene conductive additives for lithium-ion batteries. J Mater Chem 20:9644–9650

Li N, Chen ZP, Ren WC, Li F, Cheng HM (2012) Flexible graphene-based lithium ion batteries with ultrafast charge and discharge rates. Proc Natl Acad Sci USA 109:17360–17365

Wang HM, Wu YH, Cong CX, Shang JZ, Yu T (2010) Hysteresis of electronic transport in graphene transistors. ACS Nano 4:7221–7228

Unnikrishnan B, Palanisamy S, Chen SM (2013) A simple electrochemical approach to fabricate a glucose biosensor based on graphene–glucose oxidase biocomposite. Biosens Bioelectron 39:70–75

Zhu LM, Luo LQ, Wang ZX (2012) DNA electrochemical biosensor based on thionine–graphene nanocomposite. Biosens Bioelectron 35:507–511

Hass J, de Heer WA, Conrad EH (2008) The growth and morphology of epitaxial multilayer graphene. J Phys Condens Mat 20:1–26

Sutter PW, Flege JI, Sutter EA (2008) Epitaxial graphene on ruthenium. Nat Mater 7:406–411

Dai BY, Fu L, Zou ZY et al (2011) Rational design of a binary metal alloy for chemical vapour deposition growth of uniform single-layer graphene. Nat Commun 2:1–6

Obraztsov AN, Obraztsova EA, Tyurnina AV, Zolotukhin AA (2007) Chemical vapor deposition of thin graphite films of nanometer thickness. Carbon 45:2017–2021

Leon V, Quintana M, Herrero MA et al (2011) Few-layer graphenes from ball-milling of graphite with melamine. Chem Commun 47:10936–10938

Jeon IY, Shin YR, Sohn GJ et al (2012) Edge-carboxylated graphene nanosheets via ball milling. Proc Natl Acad Sci USA 109:5588–5593

Su CY, Lu AY, Xu YP, Chen FR, Khlobystov AN, Li LJ (2011) High-quality thin graphene films from fast electrochemical exfoliation. ACS Nano 5:2332–2339

Shin H-J, Kim KK, Benayad A et al (2009) Efficient reduction of graphite oxide by sodium borohydride and its effect on electrical conductance. Adv Funct Mater 19:1987–1992

Stankovich S, Dikin DA, Piner RD et al (2007) Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 45:1558–1565

Choucair M, Thordarson P, Stride JA (2009) Gram-scale production of graphene based on solvothermal synthesis and sonication. Nat Nanotechnol 4:30–33

Hummer WS, Offema RE (1958) Preparation of graphitic oxide. J Am Chem Soc 80:1339

Skowroński JM (1986) The dilute intercalation compounds of graphite with chromium trioxide. Carbon 24:185–194

Ebert LB, Huggins RA, Brauman JI (1974) The nature of the chromium trioxide intercalation in graphite. Carbon 12:199–208

Li XL, Zhang GY, Bai XD et al (2008) Highly conducting graphene sheets and Langmuir-Blodgett films. Nat Nanotechnol 3:538–542

Mukherjee A, Kang J, Kuznetsov O et al (2011) Water-soluble graphite nanoplatelets formed by oleum exfoliation of graphite. Chem Mater 23:9–13

Shaabani A, Rezayan AH (2007) Silica sulfuric acid promoted selective oxidation of sulfides to sulfoxides or sulfones in the presence of aqueous H2O2. Catal Commun 8:1112–1116

Hernandez Y, Nicolosi V, Lotya M et al (2008) High-yield production of graphene by liquid-phase exfoliation of graphite. Nat Nanotechnol 3:563–568

Lee JH, Shin DW, Makotchenko VG et al (2009) One-step exfoliation synthesis of easily soluble graphite and transparent conducting graphene sheets. Adv Mater 21:4383–4387

Lotya M, Hernandez Y, King PJ et al (2009) Liquid phase production of graphene by exfoliation of graphite in surfactant/water solutions. J Am Chem Soc 131:3611–3620

Li D, Muller MB, Gilje S, Kaner RB, Wallace GG (2008) Processable aqueous dispersions of graphene nanosheets. Nat Nanotechnol 3:101–105

Fan XB, Peng WC, Li Y et al (2008) Deoxygenation of exfoliated graphite oxide under alkaline conditions: a green route to graphene preparation. Adv Mater 20:4490–4493

Ferrari AC, Meyer JC, Scardaci V et al (2006) Raman spectrum of graphene and graphene layers. Phys Rev Lett 97:74011–74014

Liao KM, Ding WF, Zhao B et al (2011) High-power splitting of expanded graphite to produce few-layer graphene sheets. Carbon 49:2862–2868

Yanga D, Velamakannia A, Bozoklub G et al (2009) Chemical analysis of graphene oxide films after heat and chemical treatments by X-ray photoelectron and micro-Raman spectroscopy. Carbon 47:145–152

Casiraghi C, Hartschuh A, Qian H et al (2009) Raman spectroscopy of graphene edges. Nano Lett 9:1433–1441

Chakrabarti A, Lu J, Skrabutenas JC et al (2011) Conversion of carbon dioxide to few-layer graphene. J Mater Chem 21:9491–9493

Shao YY, Wang J, Engelhard M, Wang CM, Lin YH (2010) Facile and controllable electrochemical reduction of graphene oxide and its applications. J Mater Chem 20:743–748

Chen WF, Yan LF (2010) Preparation of graphene by a low-temperature thermal reduction at atmosphere pressure. Nanoscale 2:559–563

Acknowledgements

Financial supports from the Key Program of NSFC-Guangdong Joint Fund (Grant No. U1034004) and NSFC (Grant No. 51276202) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fu, YX., Wang, XM., Mo, DC. et al. Production of monolayer, trilayer, and multi-layer graphene sheets by a re-expansion and exfoliation method. J Mater Sci 49, 2315–2323 (2014). https://doi.org/10.1007/s10853-013-7930-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7930-4