Abstract

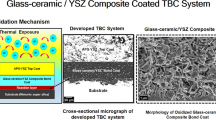

High temperature gas turbine sealing is an important issue for increasing the thermal efficiency of gas turbine. In this purpose, layered structured LaPO4 has been selected as the soft phase to add into the commercialized thermal barrier coating material 7 wt% yttria stabilized zirconia (7YSZ). The consequent thermal conductivities and mechanical properties versus the content of LaPO4 have been researched systemically in this paper. Phase composition and microstructure of the high-temperature sintered LaPO4/7YSZ composites were characterized. The thermal conductivity decreases significantly due to the second phase effects and the interface thermal resistance was also strongly involved according to the composite model. The hardness decreased by composed LaPO4 phase so that to reduce attrition of the vanes at high temperature. The slight increase of fracture toughness and bending strength in the results were also favored in operation. The experimental results demonstrate that the LaPO4/7YSZ composite will be an excellent candidate abradable sealing material for high temperature gas turbine.

Similar content being viewed by others

References

Saini A, Pollock T (2012) High-temperature materials increase efficiency of gas power plants. MRS Bull 37:550–551

Borel MO, Nicoll AR, Schlapfer HW, Schmid RK (1989) The wear mechanisms occurring in abradable seals of gas-turbines. Surf Coat Technol 39:117–126

DeMasi-Marcin JT, Gupta DK (1994) Protective coatings in the gas turbine engine. Surf Coat Technol 68–69:1–9

Hardwicke CU, Lau YC (2013) Advances in thermal spray coatings for gas turbines and energy generation: a review. J Therm Spray Technol 22:564–576

Donald IW, Mallinson PM, Metcalfe BL, Gerrard LA, Fernie JA (2011) Recent developments in the preparation, characterization and applications of glass-and glass–ceramic-to-metal seals and coatings. J Mater Sci 46:1975–2000. doi:10.1007/s10853-010-5095-y

Bardi U, Giolli C, Scrivani A, Rizzi G, Borgioli F, Fossati A, Partes K, Seefeld T, Sporer D, Refke A (2008) Development and investigation on new composite and ceramic coatings as possible abradable seals. J Therm Spray Technol 17:805–811

Wang HG (1996) Criteria for analysis of abradable coatings. Surf Coat Technol 79:71–75

Ma X, Matthews A (2009) Evaluation of abradable seal coating mechanical properties. Wear 267:1501–1510

Faraoun HI, Grosdidier T, Seichepine JL, Goran D, Aourag H, Coddet C, Zwick J, Hopkins N (2006) Improvement of thermally sprayed abradable coating by microstructure control. Surf Coat Technol 201:2303–2312

Johnston RE (2011) Mechanical characterisation of AlSi–hBN, NiCrAl–Bentonite, and NiCrAl–Bentonite–hBN freestanding abradable coatings. Surf Coat Technol 205:3268–3273

Richardt K, Bobzin K, Sporer D, Schlafer T, Fiala P (2008) Tailor-made coatings for turbine applications using the Triplex Pro 200. J Therm Spray Technol 17:612–616

Novinski E, Harrington J, Klein J (1982) Modified zirconia abradable seal coating for high temperature gas turbine applications. Thin Solid Films 95:255–263

Bounazef M, Guessasma S, Saadi BA (2004) The wear, deterioration and transformation phenomena of abradable coating BN–SiAl-bounding organic element, caused by the friction between the blades and the turbine casing. Mater Lett 58:3375–3380

Matějíček J, Kolman B, Dubský J, Neufuss K, Hopkins N, Zwick J (2006) Alternative methods for determination of composition and porosity in abradable materials. Mater Charact 57:17–29

Cao XQ, Vassen R, Stoever D (2004) Ceramic materials for thermal barrier coatings. J Eur Ceram Soc 24:1–10

Zhao M, Zhang LX, Pan W (2012) Properties of yttria-stabilized-zirconia based ceramic composite abradable coatings. Key Eng Mater 512-515:1551–1554 (High-Performance Ceramics VII, Pts 1 and 2)

Luo YM, Pan W, Li SQ, Wang RG, Li JQ (2003) Fabrication of Al2O3–Ti3SiC2 composites and mechanical properties evaluation. Mater Lett 57:2509–2514

Yi MZ, He JW, Huang BY, Zhou HJ (1999) Friction and wear behavior and abradability of abradable seal coating. Wear 231:47–53

Ma X, Matthews A (2007) Investigation of abradable seal coating performance using scratch testing. Surf Coat Technol 202:1214–1220

Kawakame M, Bressan JD (2006) Study of wear in self-lubricating composites for application in seals of electric motors. J Mater Process Technol 179:74–80

Clegg MA, Mehta MH (1988) NiCrAl/Bentonite thermal spray powder for high-temperature abradable seals. Surf Coat Technol 34:69–77

Du AB, Wan CL, Qu ZX, Pan W (2009) Thermal conductivity of monazite-type REPO4 (RE = La, Ce, Nd, Sm, Eu, Gd). J Am Ceram Soc 92:2687–2692

Hikichi Y, Nomura T (1987) Melting temperatures of monazite and xenotime. J Am Ceram Soc 70:C252–C253

Morgan P, Marshall DB (1995) Ceramic composites of monazite and alumina. J Am Ceram Soc 78:1553–1563

Padture NP, Gell M, Jordan EH (2002) Thermal barrier coatings for gas-turbine engine applications. Science 296:280–284

Min W, Daimon K, Matsubara T, Hikichi Y (2002) Thermal and mechanical properties of sintered machinable LaPO4–ZrO2 composites. Mater Res Bull 37:1107–1115

Davis JB, Marshall DB, Housley RM, Morgan P (1998) Machinable ceramics containing rare-earth phosphates. J Am Ceram Soc 81:2169–2175

Kuo DH, Kriven WM (1998) Fracture of multilayer oxide composites. Mater Sci Eng A 241:241–250

Liang YJ, Che YC, Liu XX, Li NJ (1993) Manual of practical inorganic matter thermodynamics. Northeastern University Press, Shenyang

Schlichting KW, Padture NP, Klemens PG (2001) Thermal conductivity of dense and porous yttria-stabilized zirconia. J Mater Sci 36:3003–3010. doi:10.1023/A:1017970924312

Ma D, Zhang QC (1989) Acoustic measurement of elastic constant for ceramic materials. J Inorg Mater 4:362–367

Lankford J (1982) Indentation microfracture in the palmqvist crack regime—implications for fracture-toughness evaluation by the indentation method. J Mater Sci Lett 1:493–495

Rice RW, Wu CC, Borchelt F (1994) Hardness-grain-size relations in ceramics. J Am Ceram Soc 77:2539–2553

Maxwell-Garnett JC (1904) Colours in metal glasses and in metallic films. Phil Trans R Soc London A 203:385–420

Benvensite Y (1987) Effective thermal conductivity of composites with a thermal contact resistance between the constituents: nondilute case. J Appl Phys 61:2840–2843

Hasselman DPH, Johnson LF (1987) Effective thermal conductivity of composites with interfacial thermal barrier resistance. J Comput Mater 21:508–515

Du AB, Pan W, Ahmad K, Shi SL, Qu ZX, Wan CL (2009) Enhanced mechanical properties of machinable LaPO4/Al2O3 composites by spark plasma sintering. Int J Appl Ceram Technol 6:236–242

Callister WD Jr (1990) Materials science and engineering: an introduction, 2nd edn. Wiley, New York

Tomaszewski H, Węglarz H, Wajler A, Boniecki M, Kalinski D (2007) Multilayer ceramic composites with high failure resistance. J Eur Ceram Soc 27:1373–1377

Acknowledgements

This research was supported by the National Natural Science Foundation of China (No. 51272120).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ren, X., Guo, S., Zhao, M. et al. Thermal conductivity and mechanical properties of YSZ/LaPO4 composites. J Mater Sci 49, 2243–2251 (2014). https://doi.org/10.1007/s10853-013-7919-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7919-z