Abstract

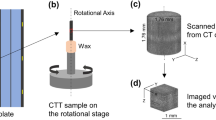

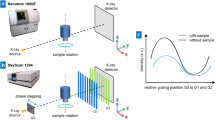

The present work deals with the measurement of fibre orientation angles in composites. A study by Bax and Müssig [1] investigated the mechanical properties (tensile and impact characteristics) of injection-moulded flax and Cordenka-reinforced polylactide (PLA) composites with fibre mass fractions between 10 and 30 %. Raising the fibre content from 10 to 30 % resulted in an increase in tensile characteristics, but it was noted that a reinforcement with 10 % flax fibres led to poorer tensile strength as compared to the neat PLA matrix. This behaviour was not expected and needs clarification. Therefore, test specimens with a fibre content of 10 and 30 mass % were examined for their fibre orientations and void content. For the investigations, microcomputer tomography images were created by monochromatic synchrotron radiation. Fibre orientation angles of these micrographs were determined with an adapted measuring mask of the Fibreshape software. It could be shown that the fibre orientation in the composite is dependent on the fibre mass fraction and the type of fibre. No voids were found in all the investigated composites. The average fibre orientation angle of 10 % flax/PLA showed a larger deviation from the longitudinal axis of the test specimen than the other samples, and is made primarily responsible for the lower tensile strength of this composite.

Similar content being viewed by others

Notes

The shape factor compares the surface of an object with the area of a circle [S = (circumference of the object)²/(4 * π * area of the object)].

References

Bax B, Müssig J (2008) Impact and tensile properties of PLA/cordenka and PLA/flax composites. Compos Sci Technol 68(7–8):1601–1607

John MJ, Thomas S (2008) Review: Biofibres and biocomposites. Carbohydr Polym 71(3):343–364

Holbery J, Houston D (2006) Natural-fiber-reinforced polymer composites in automotive applications. JOM 58(11):80–86

Faruk O, Bledzki AK, Fink H-P, Sain M (2012) Biocomposites reinforced with natural fibers: 2000–2010. Prog Polym Sci 37(11):1552–1596

Ruys D, Crosky A, Evans WJ (2002) Natural bast fibre structure. Int J Mater Prod Technol 17(1–2):2–10

Mueller (2005) Cotton fiber nonwovens for automotive composites. In: INJ Spring S. 34–40

Ma H, Joo CW (2011): Influence of surface treatments on structural and mechanical properties of bamboo fiber-reinforced poly(lactic acid) biocomposites. In: J Compos Mater, In press

Awal A, Cescutti G, Ghosh S, Müssig J (2011) Interfacial studies of natural fibre/polypropylene composites using single fibre fragmentation test (SFFT). Compos A Appl Sci Manuf 42(1):50–56

Islam M, Pickering K, Foreman N (2010) Influence of alkali treatment on the interfacial and physico-mechanical properties of industrial hemp fibre reinforced polylactic acid composites. Compos A Appl Sci Manuf 41(5):596–603

Graupner N (2009) Improvement of the mechanical properties of biodegradable hemp fiber reinforced poly(lactic acid) (PLA) composites by the admixture of man-made cellulose fibers. J Compos Mater 43(6):689–702

Graupner N, Müssig J (2011) A comparison of the mechanical characteristics of kenaf and lyocell fibre reinforced poly(lactic acid) (PLA) and poly(3-hydroxybutyrate) (PHB) composites. Compos A Appl Sci Manuf 42:2010–2019

Madsen B (2004) Properties of plant fibre yarn polymer composites -an experimental study. Dissertation, Technical University of Denmark, Department of Civil Engineering (BYG), DK

Hu R-H, Jang M-H, Kim Y-J, Piao Y-J (2010) Fully degradable jute fiber reinforced polylactide composites applicable to car interior panel. Adv Mater Res 123–125:1151–1154

Yu T, Li Y, Ren J (2009) Preparation and properties of short natural fiber reinforced poly(lactic acid) composites. In: Transactions of Nonferrous Metals Society of China, 19 (Supplement 3): 651–655

Xiao-Yun W, Qiu-Hong W, Gu H (2010) Research on mechanical behaviors of the flax/polyactic acid composites. In: J Reinf Plast Compos, 29(17): 2561–2567

Thomason JL (1999) The influence of fibre properties of the performance of glass-fibre-reinforced polyamide 6, 6. Compos Sci Technol 59(16):2315–2328

Toll S, Andersson P-O (1993) Microstructure of long-and short-fiber reinforced injection molded polyamide. Polym Compos 14(2):116–125

Akay M, Barkley D (1991) Fibre orientation and mechanical behaviour in reinforced thermoplastic injection mouldings. J Mater Sci 26(10):2731–2742

Taha IMA (2007) Processing and characterisation of selected discontinous natural fibres and their polymer composites. Dissertation, Institut für Polymerwerkstoffe und Kunststofftechnik, TU Clausthal, Fakultät für Materialwissenschaften, Clausthal, D

Walther T, Donath T, Terzic K, Meine H, Thömen H, Beckmann F (2006) Microstructural investigations on natural fiber composites and medium density fiberboard (MDF), In: Deutsches Elektronen Synchroton (Hrsg.), HASYLAB Annual Report, S. 455–456. Hamburg, D

Lux J, Delisée C, Thibault X (2006) 3D characterization of wood based fibrous materials: an application. Imag Anal Stereol 25(1):25–35

Shen H, Nutt S, Hull D (2004) Direct observation and measurement of fiber architecture in short fiber-polymer composite foam through micro-ct imaging. Compos Sci Technol 64(13–14):2113–2120

Cendre E, Feih S, Stampanoni M (2003) Characterisation of glassfiber polymer composites using X-ray synchrotron micro-tomography, In: Paul Scherrer Institut (Hrsg.), PSI -Scientific Report 2003/Volume VII, S. 56–57. Villigen, CH

Alemdar A, Zhang H, Sain M, Cescutti G, Müssig J (2008) Determination of fiber size distributions of injection moulded polypropylene/natural fibers using X-ray microtomography. Adv Eng Mater 10(12):126–130

Ganster J, Fink H-P (2006) Novel cellulose fibre reinforced thermoplastic materials. Cellulose 13(3):271–280

Beckmann F, Herzen J, Haibel A, Müller B, Schreyer A (2008): High density resolution in synchrotron-radiation-based attenuation-contrast microtomograph. In: Proceedings of SPIE, P. 7078–7081D

Schmid HG, Dvorak M, Müller J, Müssig J (2004) Characterizing flock fibers using quantitative image analysis. In: Flock -English issue 30(1):6–12

Schmid HG, Müssig J (2004): Characterisation of polyamide fibre width using quantitative image analysis. In: Melliand English, 85(10): E 110

Beckermann G, Pickering K (2009) Engineering and evaluation of hemp fibre reinforced polypropylene composites: micro-mechanics and strength prediction modelling. Compos A Appl Sci Manuf 40(2):210–217

Thomason JL (2007) The influence of fibre length and concentration on the properties of glass fibre reinforced polypropylene: 7. Interface strength and fibre strain in injection moulded long fibre PP at high fibre content. Compos A Appl Sci Manuf 38(1):210–216

Fara S, Pavan A (2004) Fibre orientation effects on the fracture of short fibre polymer composites: On the existence of a critical fibre orientation on varying internal material variables. J Mater Sci 39(11):3619–3628

Kelly A, Tyson WR (1964) Fiber strengthened materials. In: Zackay VF (ed) High-strength materials. John Wiley & Sons, Berkeley, USA

Burgstaller C, Rüt W, Stadlbauer W, Pilz G, Lang RW (2009) Utilizing unbleached cellulosic fibres in polypropylene matrix composites for injection moulding applications. In J Biobased Mater Bioenergy 3(3):226–231

Deutsches Institut für Normung (1977) DIN EN 61:1977: Glasfaser-verstärkte Kunststoffe -Zugversuch. Deutsche Norm.—in German

Beckmann F (1998) Entwicklung, Aufbau und Anwendung eines Verfahrens der Phasenkontrast-Mikrotomographie mit Röntgen-Synchrotonstrahlung. Dissertation, University of Dortmund.—in German

Acknowledgements

Our special thank is expressed to DESY (Deutsches Elektronen-Synchroton, Hamburg, Germany) who funded the project called ‘Using μ-CT for the measurement of fibre orientations in biodegradable cellulose fibre-reinforced poly(lactic acid) (PLA) composites’.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Graupner, N., Beckmann, F., Wilde, F. et al. Using synchroton radiation-based micro-computer tomography (SR μ-CT) for the measurement of fibre orientations in cellulose fibre-reinforced polylactide (PLA) composites. J Mater Sci 49, 450–460 (2014). https://doi.org/10.1007/s10853-013-7724-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7724-8