Abstract

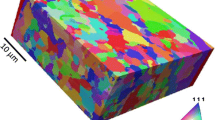

In this study, the microstructural evolution of yttria-stabilized ZrO2 after different sintering conditions is quantitatively presented. Focused ion beam (FIB) is used as a critical tool for sintering microstructural evolution understanding. 3D images are constructed with Amira software based on a series of 2D images obtained from FIB cutting of samples with an interval of 10 nm. Pore connectivity, pore numbers, grain-pore interfacial areas, and pore tortuosity of the sintered samples are calculated by IDL software using the 3D images. Our new tortuosity definition describes the actual sample microstructural changes while the other two in the literature fail to do so. FIB cutting and 3D microstructure reconstruction offer many new aspects of sintering microstructure that have not been available before.

Similar content being viewed by others

References

Lu K (2008) Int Mater Rev 53(1):21

Anonymous (2005) Am Ceram Soc Bull 84(12):3

Fang ZZ, Wang H (2008) Int Mater Rev 53(6):326

Kerkwijk B, Winnubst L, Mulder EJ, Verweij H (1999) J Am Ceram Soc 82(8):2087

Lima RS, Marple BR (2008) Mater Sci Eng 485(1–2):182

Itatani K, Tsuchiya K, Sakka Y, Davies IJ, Koda S (2011) J Eur Ceram Soc 31(14):2641

Kuang X, Carotenuto G, Nicolais L (1997) Adv Perform Mater 4(3):257

Dahl P, Kaus I, Zhao Z, Johnsson M, Nygren M, Wiik K, Grande T, Einarsrud MA (2007) Ceram Int 33(8):1603

Mazaheri M, Zahedi AM, Sadrnezhaad SK (2008) J Am Ceram Soc 91(1):56

Conrad H, Yang D (2011) Mater Sci Eng 528(29–30):8523

Conrad H, Yang D (2013) Mater Sci Eng 559(1):591

Wilson JR, Kobsiriphat W, Mendoza R, Chen H-Y, Hiller JM, Miller DJ, Thornton K, Voorhees PW, Adler SB, Barnett SA (2006) Nat Mater 5(7):541

Jasti JK, Jesion G, Feldkamp L (1993) SPE Form Eval 8(3):189

Chung HW, Wehrli FW, Williams JL, Wehrli SL (1995) J Bone Miner Res 10(10):1452

Gilbe C, Ohman M, Lindstrom E, Bostrom D, Backman R, Samuelsson R, Burvalll J (2008) Energy Fuels 22(5):3536

Beckmann F, Grupp R, Haibel A, Huppmann M, Noethe M, Pyzalla A, Reimers W, Schreyer A, Zettler R (2007) Adv Eng Mater 9(11):939

Landis EN, Keane DT (2010) Mater Charact 61(12):1305

Guan Y, Li WJ, Gong YH, Liu G, Zhang XB, Chen J, Gelb J, Yun WB, Xiong Y, Tian YC, Wang HQ (2011) J Power Sources 196(4):1915

Yoshizawa N, Tanaike O, Hatori H, Yoshikawa K, Kondo A, Abe T (2006) Carbon 44(12):2558

Bals S, Batenburg KJ, Verbeeck J, Sijbers J, Van Tendeloo G (2007) Nano Lett 7(12):3669

Wu YQ, Tang W, Dennis KW, Oster N, McCallum RW, Anderson IE, Kramer MJ (2011) J Appl Phys 109(7):07A705

Trtik P, Munch B, Gasser P, Leemann A, Loser R, Wepf R, Lura P (2011) J Microsc 241(3):234

Caballero FG, Miller MK, Garcia-Mateo C (2011) Metall Mater Trans A 42A(12):3660

Kuchibhatla SVNT, Shutthanandan V, Prosa TJ, Adusumilli P, Arey B, Buxbaum A, Wang YC, Tessner T, Ulfig R, Wang CM, Thevuthasan S (2012) Nanotechnology 23(21):215704

Rollett AD, Lee SB, Campman R, Rohrer GS (2007) Annu Rev Mater Res 37:627

Gostovic D, Smith JR, Kundinger DP, Jones KS, Wachsman ED (2007) Electrochem Solid-State Lett 10(12):B214

Vivet N, Chupin S, Estrade E, Richard A, Bonnamy S, Rochais D, Bruneton E (2011) J Power Sources 196(23):9989

Gunda NSK, Choi HW, Berson A, Kenney B, Karan K, Pharoah JG, Mitra SK (2011) J Power Sources 196(7):3592

Chater RJ, Corni I, Boccaccini AR, Ryan MP (2011) Surf Interface Anal 43(1–2):492

Cronin JS, Muangnapoh K, Patterson Z, Yakal-Kremski KJ, Dravid VP, Barnett SA (2012) J Electrochem Soc 159(4):B385

Gostovic D, Vito NJ, O’Hara KA, Jones KS, Wachsmanw ED (2011) J Am Ceram Soc 94(2):620

Yoon KJ, Cramer CN, Stevenson JW, Marina OA (2010) J Power Sources 195(22):7587

Ahn ES, Gleason NJ, Nakahira A, Ying JY (2001) Nano Lett 1(3):149

De Aza AH, Chevalier J, Fantozzi G, Schehl M, Torrecillas R (2002) Biomaterials 23(3):937

Guo F, Javed A, Shapiro IP, Xiao P (2012) J Eur Ceram Soc 32(1):211

Yang D, Conrad H (2010) Scr Mater 63(3):328

Nettleship I, Chen T, Ewsuk K (2007) J Am Ceram Soc 90(12):3793

Obare J, Griffin WD, Conrad H (2012) J Mater Sci 47(13):5141. doi:10.1007/s10853-012-6391-5

Bullitt E, Gerig G, Pizer SM, Lin WL, Aylward SR (2003) IEEE Trans Med Imaging 22(9):1163

Lorenzano-Porras CF, Annen MJ, Flickinger MC, Carr PW, McCormick AV (1995) J Colloid Interface Sci 170(2):299

Lorenzano-Porras CF, Carr PW, McCormick AV (1994) J Colloid Interface Sci 164(1):1

Acknowledgements

This study was supported by National Science Foundation under Grant No. CMMI-0969888.

Author information

Authors and Affiliations

Corresponding author

Additional information

Kathy Lu is the member of American Ceramic Society.

Rights and permissions

About this article

Cite this article

Xia, Z., Chen, B. & Lu, K. 3D microstructure construction and quantitative evaluation of sintered ZrO2 under different sintering conditions. J Mater Sci 48, 5852–5861 (2013). https://doi.org/10.1007/s10853-013-7381-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7381-y