Abstract

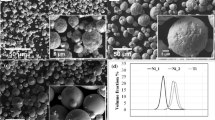

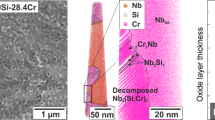

A Ni–Cr–B-Si–C alloy powder was modified by addition of 2 and 5 wt% of vanadium to tackle the high cracking sensitivity of the original composition during laser deposition. The effects of vanadium on microstructure and phases were investigated by Scanning Electron Microscopy, Energy Dispersive Spectroscopy, and Transmission Electron Microscopy (TEM) and the changes in the hardness and cracking tendency of the deposits were evaluated. In comparison to the original composition, V-modified alloys produced deposits with lower hardness and moderately reduced cracking tendencies. Addition of vanadium transformed the nature and the morphology of the boride precipitates and added VC particles to the microstructure but did not induce a significant microstructural refinement. TEM characterizations confirmed that borides phases in the modified deposits consisted of alternating layers of CrB and (Cr1−xVx)B but the VC existed as independent particles which were formed on the boride precipitates. The final phase constitution of the modified alloys was dramatically influenced by the complete solid solubility between CrB and VB and the lack of solubility between Cr7C3 and VC. Addition of vanadium did not provide the phases which could act as nucleation sites to refine the microstructure of the deposits because VB had a tendency to dissolve in CrB and VC was formed at low temperatures on the boride phases. The outcomes of this study can be used to evaluate the effects of adding early transition metals such as vanadium on the microstructure and phase formations of the Ni–Cr–B-Si–C alloys.

Similar content being viewed by others

References

Conde A, Zubiri F, De Damborenea YJ (2002) Mater Sci Eng A 334:233

Hemmati I, Ocelik V, De Hosson JThM (2011) Contact mechanics and surface treatments X. WIT Press, Malta, p 287

Zhang H, Shi Y, Kutsuna M, Xu GJ (2010) Nucl Eng Des 240:2691

Fernández E, Cadenas M, González R, Navas C, Fernández R, Damborenea JD (2005) Wear 259:870

Huang Y, Zeng X (2010) Appl Surf Sci 256:5985

Wang D-S, Liang E, Chao M, Yuan B (2008) Surf Coat Technol 202:1371

Wang F, Mao H, Zhang D, Zhao X, Shen Y (2008) Appl Surf Sci 255:3267

Chao M-J, Liang E-J (2004) Surf Coat Technol 179:265

Yu T, Deng Q, Dong G, Yang J (2011) Appl Surf Sci 257:5098

Hemmati I, Rao JC, Ocelik V, De Hosson JTM (2013) Microsc Microanal 19:1

Hertzberg RW, Vinci RP, Hertzberg JL (2012) Deformation and fracture mechanics of engineering materials. Wiley, Hoboken

Barin I (1995) Thermochemical data of pure substances. VCH, Weinheim

Toyserkani E, Corbin S, Khajepour A (2004) Laser cladding. CRC Press, Florida

Cockeram BV (1998) Surf Coat Technol 108–109:377

Ocelík V, Eekma M, Hemmati I, De Hosson JTM (2012) Surf Coat Technol 206:2403

Hemmati I, Ocelík V, De Hosson JThM (2012) Mater Lett 84:69

Kuz’ma YB, Telegus VS, Kovalyk DA (1969) Sov Powder Metall Met Ceram 8:403

Clementi E, Raimondi DL, Reinhardt WP (1967) J Chem Phys 47:1300

Hugh Pierson O (1996) Handbook of refractory carbides and nitrides: properties, characteristics, processing, and applications. Noyes Publications, Park Ridge

Acknowledgements

This research was carried out under project number MC7.06259 in the framework of the Research Program of the Materials innovation institute M2i (www.m2i.nl). The Wall Colmonoy Ltd. (The UK) is acknowledged for providing the cladding powders.

Author information

Authors and Affiliations

Corresponding author

Additional information

J.C. Rao—On leave from Institute for Advanced Ceramics, Department of Materials Science, Harbin Institute of Technology, Harbin 150001, China.

Rights and permissions

About this article

Cite this article

Hemmati, I., Rao, J.C., Ocelík, V. et al. Phase formation and properties of vanadium-modified Ni–Cr–B-Si–C laser-deposited coatings. J Mater Sci 48, 3315–3326 (2013). https://doi.org/10.1007/s10853-012-7117-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-7117-4