Abstract

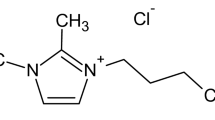

Nanocomposites of montmorillonite organoclays and polypropylene (PP) were prepared via direct melt intercalation using maleic anhydride functionalized polypropylene (PP-g-MA) as a compatibilizer. Two montmorillonite clays (MMT) with different cation exchange capacities (CEC) were exchanged with alkyl ammonium ions, in which one or two octadecyl chains are attached to the nitrogen atom. The role of alkyl chain numbers and CEC value on the dispersion of clay and rheology of PP nanocomposites under shear and extensional flow was evaluated by X-ray diffraction, scanning electron microscopy, and rheologic techniques. It was found that the low-CEC organoclay with one alkyl chain could only form a conventional composite. However, the low-CEC organoclay with two alkyl chains or high-CEC organoclay with one alkyl chain can disperse finely in the matrix. Nanocomposites containing these two organoclays showed typical shear rheologic properties of intercalated nanocomposites, but only the former showed a mild strain-hardening behavior in uniaxial extensional flow. When using an intercalant with two tails, the high-CEC clay would lead the organoclay to form mixed structures which further resulted in an inferior dispersion quality. It was proposed that the dispersion quality and rheologic properties of nanocomposites were related to the arrangement of modifier molecules in the clay galleries, which was determined by the CEC of clay and the structure of alkyl ammonium ions.

Similar content being viewed by others

References

Alexandre M, Dubois P (2000) Mater Sci Eng 28(1–2):1

Vermant J, Ceccia S, Dolgovskij M, Maffettone P, Macosko C (2007) J Rheol 51:429

Yoo Y, Paul D (2008) Polymer 49(17):3795

Solomon MJ, Almusallam AS, Seefeldt KF, Somwangthanaroj A, Varadan P (2001) Macromolecules 34(6):1864

Hotta S, Paul D (2004) Polymer 45(22):7639

Reichert P, Nitz H, Klinke S, Brandsch R, Thomann R, Mülhaupt R (2000) Macromol Mater Eng 275(1):8

Galgali G, Ramesh C, Lele A (2001) Macromolecules 34(4):852

Rajabian M, Naderi G, Dubois C, Lafleur PG (2010) Rheol Acta 49(1):105

Okamoto M, Nam PH, Maiti P, Kotaka T, Hasegawa N, Usuki A (2001) Nano Lett 1(6):295

Hwan Lee S, Cho ENR, Youn JR (2007) J Appl Polym Sci 103(6):3506

Kanny K, Jawahar P, Moodley V (2008) J Mater Sci 43(22):7230. doi:10.1007/s10853-008-2938-x

Dong Y, Bhattacharyya D (2012) J Mater Sci 47(8):3900. doi:10.1007/s10853-012-6248-y

Shah RK, Hunter D, Paul D (2005) Polymer 46(8):2646

Bae SB, Kim CK, Kim K, Chung IJ (2008) Eur Polym J 44(11):3385

Chavarria F, Paul D (2006) Polymer 47(22):7760

Fornes T, Yoon P, Hunter D, Keskkula H, Paul D (2002) Polymer 43(22):5915

Fornes T, Hunter D, Paul D (2004) Macromolecules 37(5):1793

Velasco J, Ardanuy M, Realinho V, Antunes M, Fernández A, González-Peña J, Rodríguez-Pérez M, de Saja J (2006) J Appl Ploym Sci 102(2):1213

Janowska G, Mikołajczyk T, Olejnik M (2008) J Therm Anal Calorim 92(2):495

Ratinac KR, Gilbert RG, Ye L, Jones AS, Ringer SP (2006) Polymer 47(18):6337

Sheng D, Tan J, Liu X, Wang P, Yang Y (2011) J Mater Sci 46(20):6508. doi:10.1007/s10853-011-5597-2

Kornmann X, Lindberg H, Berglund LA (2001) Polymer 42(4):1303

Lan T, Pinnavaia TJ (1994) Chem Mater 6(12):2216

Osman MA, Rupp JEP, Suter UW (2005) J Mater Chem 15(12):1298

Osman MA, Rupp JEP, Suter UW (2005) Polymer 46(5):1653

Fornes T, Yoon P, Keskkula H, Paul D (2001) Polymer 42(25):09929

Xidas PI, Triantafyllidis KS (2010) Eur Ploym J 46(3):404

Sanchez-Solis A, Garcia-Rejon A, Estrada M, Martinez-Richa A, Sanchez G, Manero O (2005) Polym Int 54(12):1669

De Paiva LB, Morales AR, Valenzuela Díaz FR (2008) Appl Clay Sci 42(1–2):8

Hodder P, Franck A (2005) Ann Trans Nord Rheol Soc 13:227

Rohlmann CO, Horst MF, Quinzani LM, Failla MD (2008) Eur Ploym J 44(9):2749

Leszczynska A, Njuguna J, Pielichowski K, Banerjee J (2007) Thermochim Acta 454(1):1

Pozsgay A, Fráter T, Százdi L, Müller P, Sajó I, Pukánszky B (2004) Eur Polym J 40(1):27

Li J, Ton-That MT, Tsai SJ (2006) Polym Eng Sci 46(8):1060

Xie W, Gao Z, Pan WP, Hunter D, Singh A, Vaia R (2001) Chem Mater 13(9):2979

LeBaron PC, Wang Z, Pinnavaia TJ (1999) Appl Clay Sci 15(1–2):11

Park CI, Kim MH, Ok Park O (2004) Polymer 45(4):1267

Yoon J, Jo W, Lee M, Ko M (2001) Polymer 42(1):329

Prasad R, Pasanovic-Zujo V, Gupta RK, Cser F, Bhattacharya SN (2004) Polym Eng Sci 44(7):1220

Ohl N, Gleissle W (1993) J Rheol 37(2):381

Lertwimolnun W, Vergnes B (2005) Polymer 46(10):3462

Krishnamoorti R, Ren J, Silva AS (2001) J Chem Phys 114(11):4968

Kim DH, Fasulo PD, Rodgers WR, Paul DR (2007) Polymer 48(18):5308

Lee A, Lichtenhan JD (1999) J Appl Ploym Sci 73(10):1993

Letwimolnun W, Vergnes B, Ausias G, Carreau PJ (2007) J Non-Newton Fluid Mech 141(2):167

Li Q, Yang Q, Huang Y, Chen G, Lv Y (2012) J Macromol Sci Phys. doi:10.1080/00222348.2012.659638

Tanoue S, Utracki LA, Garcia-Rejon A, Sammut P, Ton-That MT, Pesneau I, Kamal MR, Lyngaae-Jørgensen J (2004) Polym Eng Sci 44(6):1061

Singh S, Ghosh AK, Maiti SN, Raha S, Gupta RK, Bhattacharya S (2012) Polym Eng Sci 52(1):225

Acknowledgements

The authors are grateful for the financial support from the Program for New Century Excellent Talents in University (NCET-10-0576), State Education Ministry, and the National Science Foundation of China (51003062). This work was also sponsored by the International Science & Technology Cooperation Program of China (2010DFA54460) and State Key Laboratory Special Fund.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Q., Zeng, Q., Huang, Y. et al. Dispersion and rheology of polypropylene/organoclay nanocomposites: effect of cation exchange capacity and number of alkyl tails. J Mater Sci 48, 948–959 (2013). https://doi.org/10.1007/s10853-012-6820-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6820-5