Abstract

The effects of seven sintering aids (0.5 at.% Ni, Co, Fe, Cr, Zr, Nb, and Pd) on the densification of Mo–Si–B alloys of six different compositions (Mo, Mo–0.2Si, Mo–0.2Si–0.02B, Mo–2.5Si–2.5B, Mo–7Si–5B, and Mo–8.9Si–7.7B at.%) are systematically investigated. It was found that Ni, Co, and Fe are effective in enhancing densification of Mo–Si–B alloys, and Ni is the most effective sintering aid. This study supports a previously proposed hypothesis that activated sintering results from enhanced mass transport in the sintering-aid-induced quasi-liquid intergranular films (a type of grain boundary complexion). The relative effectiveness of these sintering aids can be rationalized by analyzing several key thermodynamic parameters that control the stability of premelting-like grain boundary complexions. Future studies are needed to develop interfacial thermodynamic models and methods for computing “grain boundary complexion (phase) diagrams” for multicomponent systems, which can be a useful component for the “Materials Genome” project that will enable better predictions of the activated sintering and other materials phenomena.

Similar content being viewed by others

References

German RM (1985) Liquid phase sintering. Plenum Press, New York

Kingery WD (1959) J Appl Phys 30:301

German RM, Munir ZA (1976) Metall Trans 7A:1873

Hayden HW, Brophy JH (1963) J Electrochem Soc 110:805

German RM (1982) Rev Powder Metall Phys Ceram 2:9

Coble RL, Cannon RM (1978) In: Palmour H III, Davis RF, Hare TM (eds) Processing of crystalline ceramics. Plenum Press, New York

EC Skaar (1977) M.I.T., Cambridge, MA

Luo J, Wang H, Chiang Y-M (1999) J Am Ceram Soc 82:916. doi:10.1111/j.1151-2916.1999.tb01853.x

Luo J, Gupta VK, Yoon DH, Meyer HM (2005) Appl Phys Lett 87:231902. doi:10.1063/1.2138796

Gupta VK, Yoon DH, Meyer HM III, Luo J (2007) Acta Mater 55:3131. doi:10.1016/j.actamat.2007.01.017

Luo J (2008) Curr Opin Solid State Mater Sci 12:81. doi:10.1016/j.cossms.2008.12.001

Luo J, Shi XM (2008) Appl Phys Lett 92:101901. doi:10.1063/1.2892631

Shi X, Luo J (2009) Appl Phys Lett 94:251908. doi:10.1063/1.3155443

Shi X, Luo J (2010) Phys Rev Lett 105:236102. doi:10.1103/PhysRevLett.105.236102

Shi X, Luo J (2011) Phys Rev B 84:014105. doi:10.1103/PhysRevB.84.014105

Luo J (2012) J Am Ceram Soc 95:2358. doi:10.1111/j.1551-2916.2011.05059.x

Clarke DR (1987) J Am Ceram Soc 70:15

Clarke DR, Shaw TM, Philipse AP, Horn RG (1993) J Am Ceram Soc 76:1201

Luo J (2007) Crit Rev Solid State Mater Sci 32:67. doi:10.1080/10408430701364388

Cannon RM, Esposito L (1999) Z Metallkd 90:1002

Cannon RM, Rühle M, Hoffmann MJ, et al. (2000) Ceramic transactions (grain boundary engineering in ceramics), vol 118. p 427

Scheu C, Dehm G, Kaplan WD (2001) J Am Ceram Soc 84:623

Avishai A, Scheu C, Kaplan WD (2005) Acta Mater 53:1559

Baram M, Chatain D, Kaplan WD (2011) Science 332:206

Luo J, Chiang Y-M (2008) Annu Rev Mater Res 38:227. doi:10.1146/annurev.matsci.38.060407.132431

Tang M, Carter WC, Cannon RM (2006) Phys Rev B 73:024102

Tang M, Carter WC, Cannon RM (2006) Phys Rev Lett 97:075502

Dillon SJ, Tang M, Carter WC, Harmer MP (2007) Acta Mater 55:6208

Harmer MP (2010) J Am Ceram Soc 93:301. doi:10.1111/j.1551-2916.2009.03545.x

Luo J, Cheng H, Asl KM, Kiely CJ, Harmer MP (2011) Science 333:1730. doi:10.1126/science.1208774

Cahn JW (1977) J Chem Phys 66:3667

Schick M (1990) In: Charvolin J, Joanny JF, Zinn-Justin J (eds) Les Houches Summer School Lectures. Session XLVIIIElsevier, Amsterdam

Wynblatt P, Saul A, Chatain D (1998) Acta Mater 46:2337. doi:10.1016/s1359-6454(97)00390-x

Wynblatt P, Chatain D (2008) Mater Sci Eng A 495:119. doi:10.1016/j.msea.2007.09.091

Mishin Y, Boettinger WJ, Warren JA, McFadden GB (2009) Acta Mater 57:3771

Wang H, Chiang Y-M (1998) J Am Ceram Soc 81:89

MacLaren I, Cannon RM, Gülgün MA et al (2003) J Am Ceram Soc 86:650

Straumal BB, Baretzky B (2004) Interface Sci 12:147

Divinski S, Lohmann M, Herzig C, Straumal B, Baretzky B, Gust W (2005) Phys Rev B 71:104104

Rabkin EI, Semenov VN, Shvindlerman LS, Straumal BB (1991) Acta Metall Mater 39:627

Chang LS, Rabkin E, Straumal BB, Baretzky B, Gust W (1999) Acta Mater 47:4041

Dimiduk DM, Perepezko JH (2003) MRS Bull 28:639

Schneibel JH, Ritchie RO, Kruzic JJ, Tortorelli PF (2005) Metall Mater Trans A 36A:525

Middlemas MR, Cochran JK (2008) JOM 60:19

Sakidja R, Perepezko JH, Kim S, Sekido N (2008) Acta Mater 56:5223. doi:10.1016/j.actamat.2008.07.015

Heilmaier M, Kruger M, Saage H et al (2009) JOM 61(7):61. doi:10.1007/s11837-009-0106-7

Burk S, Gorr B, Kruger M, Heilmaier M, Christ HJ (2011) JOM 63(12):32. doi:10.1007/s11837-011-0203-2

Cochran JK, Daloz WL, Marshall PE (2011) JOM 63(12):44. doi:10.1007/s11837-011-0206-z

Rioult FA, Imhoff SD, Sakidja R, Perepezko JH (2009) Acta Mater 57:4600. doi:10.1016/j.actamat.2009.06.036

Burk S, Gorr B, Christ HJ (2010) Acta Mater 58:6154. doi:10.1016/j.actamat.2010.07.034

Jain P, Kumar KS (2010) Acta Mater 58:2124. doi:10.1016/j.actamat.2009.11.054

Yang Y, Bei H, Chen SL, George EP, Tiley J, Chang YA (2010) Acta Mater 58:541. doi:10.1016/j.actamat.2009.09.032

Dash JG, Rempel AM, Wettlaufer JS (2006) Rev Mod Phys 78:695

Mellenthin J, Karma A, Plapp M (2008) Phys Rev B 78:184110. doi:18411010.1103/PhysRevB.78.184110

Wynblatt P, Chatain D, Pang Y (2006) J Mater Sci 41:7760. doi:10.1007/s10853-006-0406-z

Wynblatt P, Chatain D (2007) Metall Mater Trans A 38A:438. doi:10.1007/s11661-006-9039-8

Serre C, Chatain D, Wynblatt P, Muris M, Bienfait M (2001) Metall Mater Trans A 32A:2851

Frisk K (1990) CALPHAD 14:311

Davydov A, Kattner UR (1999) J Phase Equilib 20:5. doi:10.1361/105497199770335893

Hillert M, Qiu C (1990) Metall Mater Trans A 21:1673. doi:10.1007/bf02672583

Xiong W, Du Y, Liu Y et al (2004) CALPHAD 28:133. doi:10.1016/j.calphad.2004.07.002

Perez RJ, Sundman B (2003) CALPHAD 27:253. doi:10.1016/j.calphad.2003.09.003

Benedictus R, Böttger A, Mittemeijer EJ (1996) Phys Rev B 54:9109

Straumal BB, Baretzky B, Kogtenkova OA, Straumal AB, Sidorenko AS (2010) J Mater Sci 45:2057. doi:10.1007/s10853-009-4014-6

Zhang GJ, Lin XH, Liu G, Zhang NN, Sun J (2011) Int J Refract Metal Hard Mater 29:96. doi:10.1016/j.ijrmhm.2010.08.006

Saage H, Kruger M, Sturm D et al (2009) Acta Mater 57:3895. doi:10.1016/j.actamat.2009.04.040

Massalski TB, Okamoto H (1990) Binary alloy phase diagrams. ASM International, Materials Park

Smith JT (1965) J Appl Phys 36:595

Acknowledgements

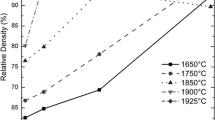

We would like to thank Zhao Zhang for experimental assistance in collecting partial data reported in Fig. 3. We gratefully acknowledge the financial support from the U.S. Air Force Office of Scientific Research (AFOSR) under the grant no. FA9550-10-1-0185 in the Aerospace Materials for Extreme Environments program, and we thank our AFOSR program manager, Dr. Ali Sayir, for his guidance and support. We sincerely thank two anonymous reviewers for their constructive comments and suggestions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jung, JI., Zhou, N. & Luo, J. Effects of sintering aids on the densification of Mo–Si–B alloys. J Mater Sci 47, 8308–8319 (2012). https://doi.org/10.1007/s10853-012-6815-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6815-2