Abstract

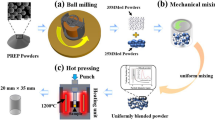

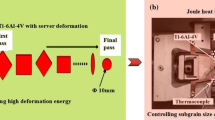

An ultrafine grained (UFG) Ti–47Al–2Cr (at.%) alloy has been synthesized using a combination of high energy mechanical milling and hot isostatic pressing (HIP) of a Ti/Al/Cr composite powder compact. The material produced has been tensile tested at room temperature, 700 and 800 °C, respectively, and the microstructure of the as-HIPed material and the microstructure and fracture surfaces of the tensile tested specimens have been examined using X-ray diffractometry, optical microscopy, scanning electron microscopy and transmission electron microscopy. The alloy shows no ductility during tensile testing at room temperature and 700 °C, respectively, but very high ductility (elongation to fracture 70–100%) when tensile tested 800 °C, indicating that its brittle to ductile transition temperature (BDTT) falls within the temperature range of 700–800 °C. The retaining of ultrafine fine equiaxed grain morphology after the large amount of plastic deformation of the specimens tensile tested at 800 °C and the clear morphology of individual grains in the fractured surface indicate that grain boundary sliding is the predominant deformation mechanism of plastic deformation of the UFG TiAl based alloy at 800 °C. Cavitation occurs at locations fairly uniformly distributed throughout the gauge length sections of the specimens tensile tested at 800 °C, again supporting the postulation that grain boundary sliding is the dominant mechanism of the plastic deformation of the UFG TiAl alloys at temperatures above their BDTT. The high ductility of the UFG alloy at 800 °C and its fairly low BDTT indicates that the material a highly favourable precursor for secondary thermomechanical processing.

Similar content being viewed by others

References

Djanarthany S, Viala JC, Bouix J (2001) Mater Chem Phys 72:301

Morris MA, Leboeuf M (1997) Mater Sci Eng A 239:429

Imayev R, Shagiev M, Salishchev G, Imayev V, Valitov V (1996) Scripta Mater 34:985

Imavey VM, Salishchev GA, Shagiev MR, Kuznetsov AV, Imavey RM, Senkov ON, Froes FH (2001) Mater Sci Eng A 300:263

Haanappel VAC, Clemens H, Stroosnijder MF (2002) Intermetallics 10:293

Rishel LL, Biery NE, Raban R, Gandelsman VZ, Pollock TM, Cramb AW (1998) Intermetallics 6:629

Gerling R, Clemens H, Schimansky FP (2004) Adv Eng Mater 6:23

Hsiung LM, Nieh TG (2004) Mater Sci Eng A 364:1

Wegmann G, Gerling R, Schimansky FP, Clemens H, Bartels A (2002) Intermetallics 10:511

Shagiev MR, Senkov ON, Salishchev GA, Froes FH (2000) J Alloy Compd 313:201

Yang SH, Kim MS, Kim WY, Chiba A (2003) J Metastab Nanocryst Mater 15–16:373

Maziasz PJ, Liu CT (1998) Metall Mater Trans A 29:105

Thomas M, Raviart JL, Popoff F (2005) Intermetallics 13:944

Yu HB, Zhang DL, Chen YY, Cao P, Gabbitas B (2009) J Alloy Compd 474:105

Chen YY, Yu HB, Zhang DL, Chai LH (2009) Mater Sci Eng A 525:166

Bohn R, Klassen T, Bormann R (2001) Intermetallics 9:559

Liu CT, Schneibe JH, Maziasz PJ, Wright JL, Easton DS (1996) Intermetallics 4:429

Kim YW (1995) Mater Sci Eng A 192/193:519

Wu Y, Li XW, Zhou SX, Hwang SK (2007) J Iron Steel Res Int 14:104

Dimiduck DM (1999) Mater Sci Eng A 263:281

Gerling R, Schimansky FP, Clemens H (2003) Wear 249:566

Wang GX, Dahms M (1993) J Mater Perform 45:52

Beddoes J, Zhao L, Au P, Wallace W (1995) Mater Sci Eng A 192/193:324

Clemens H, Glatz W, Appel F (1996) Scr Mater 35:429

Shagiev MR, Senkov ON, Salishchev GA, Froes FH (2000) J Alloy Compd 313:201

Acknowledgements

The authors would like to thank the Foundation for Research, Science, and Technology (FRST), New Zealand for the financial support to the research work presented in this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nadakuduru, V.N., Zhang, D.L., Gabbitas, B. et al. Tensile properties and fracture behaviour of an ultrafine grained Ti–47Al–2Cr (at.%) alloy at room and elevated temperatures. J Mater Sci 47, 1223–1233 (2012). https://doi.org/10.1007/s10853-011-5887-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5887-8