Abstract

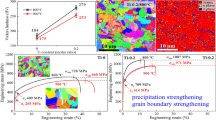

In this study, an attempt to investigate the role of isothermal aging on the microstructure and dry sliding wear behavior of Co–28Cr–5Mo–0.3C alloy was made. Regarding the results, it is clear that isothermal aging at 850 °C for 8 and 16 h contributed to the formation of lamellar type carbides (γ-fcc + M23C6) at the grain boundary regions. Moreover, at higher aging times (24 h), the lamellar type carbides decreased whereas severe precipitation of carbides was found to occur on the stacking faults. Furthermore, according to X-ray diffraction results, 24 h isothermal aging of solution treated specimens did not lead to complete fcc → hcp transformation. The wear properties of as-cast and heat treated samples were determined at 0.5 ms−1 speed several under normal applied loads such as 50, 80, and 110 N. At the lowest load applied (50 N), isothermally aged specimens for 8 and 16 h have higher wear resistance probably due to more volume fraction of lamellar-type carbides when compared to as-cast for both 4 and 24 h aged specimens. But, at higher applied loads (80 and 110 N) due to the formation of adhesive oxide layer on the as-cast specimen surface, the wear rate of as-cast samples is lower compared with all heat treated specimens.

Similar content being viewed by others

References

Saldivar AJ, Lopez HF (2001) Scr Mater 45:427

Upadhyay D, Panchal MA, Dubey RS, Srivastava VK (2006) Mater Sci Eng A 432:1

Huang P, Lopez HF (1999) Mater Lett 39:249

Montero-Ocampo C, Talavera M, Lopez HF (1999) Metall Mater Trans A 30:611

Lashgari HR, Zangeneh Sh, Hasanabadi F, Saghafi M (2010) Mater Sci Eng A 527:4082

Zangeneh Sh, Lashgari HR, Saghafi M, Karshenas M (2010) Mater Sci Eng A 527:6494

Garcia A, Medrano A, Rodriguez A (1999) Metall Mater Trans 30:1177

Garza Z, Herrera-Trejo M, Castro M, Ramı´rez E, Me´ndez M, Me´ndez J (2001) J Mater Eng Perf 10:153

Escobedo J, Mendez J, Cortes D, Gomez J, Mendez M, Mancha H (1996) Mater Des 17:79

Ramiırez-Vidaurri LE, Castro-Roman M, Herrera-Trejo M, Garcia-Lopez CV, Almanza-Casas E (2009) J Mater Proc Technol 209:1681

Taylor RNJ, Waterhouse RB (1983) J Mater Sci 18:3265. doi:https://doi.org/10.1007/BF00544151

Giacchi JV, Morando CN, Fornaro O, Palacio HA (2011) Mater Charact 62:52

Lopez HF, Saldivar-Garcia AJ (2008) Metall Mater Trans A 39:8

ASM Handbook (1992) In: Friction, lubrication, and wear technology, vol. 18. ASM International, Hardcover

Ueda M, Uchino K, Kobayashi A (2002) Wear 253:107

Clayton P (1980) Wear 60:75

Bhushan B (ed) (2001) In: Modern tribology handbook, vol. 1. CRC press LLC, Boca Raton

Bhansali KJ, Miller AE (1982) Wear 75:241

Yu H, Ahmed R, Lovelock HV, Davies S (2009) J Tribo 131:11601

Clemow AJT, Daniell BL (1980) Wear 61:219

Haung P, Rodriguez AS, Lopez HF (1999) Mater Sci Tech 15:1324

Acknowledgement

H. R. Lashgari wishes to acknowledge the assistance of Mr. Saghafi for operating SEM in this project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lashgari, H.R., Zangeneh, S. & Ketabchi, M. Isothermal aging effect on the microstructure and dry sliding wear behavior of Co–28Cr–5Mo–0.3C alloy. J Mater Sci 46, 7262–7274 (2011). https://doi.org/10.1007/s10853-011-5686-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5686-2