Abstract

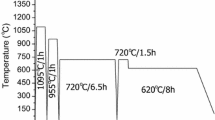

The effect of heat treatments on the creep–rupture properties was investigated on a wrought Ni–Cr heat-resistant alloy at 973 K. Short-time aging (aging for 3.6 ks (1 h) at 973 K) was made on the solution-treated specimens with different grain sizes. The fine-grained specimen (the grain diameter, d = 45.2 μm) produced by short-time solution treatment exhibited almost the same rupture life and superior creep ductility as those of the medium-grained specimen (d = 108 μm) produced by normal solution treatment. The fine-grained specimen and medium-grained specimen showed the longer rupture life compared with the specimen with recommended aging. The principal strengthening of specimens was attributed to the precipitation hardening by γ′ phase particles. The fine-grained specimen had the highest hardness, and the increase of the hardness was observed in both the fine-grained and the medium-grained specimens during creep at 973 K. However, coarse-grained specimen (d = 286 μm) with high-temperature long-time solution treatment exhibited significantly short rupture life owing to insufficient precipitation hardening after the short-time aging and during creep. Ductile intergranular fracture with dimples occurred in the fine-grained specimen, while brittle intergranular fracture was observed in the medium-grained specimen and in the specimen with recommended aging. Both transgranular fracture and brittle intergranular fracture were observed in the coarse-grained specimen. A simple heat treatment composed of short-time solution treatment and short-time aging is applicable to high-temperature components of wrought Ni–Cr alloys.

Similar content being viewed by others

References

Donachie M, Donachie S (2002) Superalloys, 2nd edn. ASM International, Materials Park, Ohio

Wisniewski A, Beddoes J (2009) Mater Sci Eng A 510–511:266

Raymond EL (1967) Trans Metall Soc AIME 239(9):1415

Venkiteswaran PK, Taplin DMR (1974) Met Sci 8(1):97

Arbel A, Pande CS (1988) J Mater Sci 23(9):3375. doi:10.1007/BF00551321

Jahazi M, Mashreghi AR (2002) Mater Sci Technol 18(4):458

Sims CT, Hagel WC (1972) The superalloys. Wiley, New York

Sims CT, Stoloff NS, Hagel WC (1987) Superalloys II. Wiley, New York

Garofalo F, Domis W, von Gemmingen F (1964) Trans Met Soc AIME 230(10):1460

Tanaka M, Kato R, Ito Y, Kayama A (2000) Z Metallkd 91(5):429

Lagneborg RJ (1969) J Iron Steel Inst 207(11):1503

Barrett CR, Lytton JL, Sherby OD (1967) Trans Met Soc AIME 239(1):170

Evans HE (1984) Mechanisms of creep fracture. Elsevier Applied Science Publishers, London

McElroy RJ, Szkopiak ZC (1972) Int Metall Rev 17:175

McQueen HJ (1977) Metall Trans A 8A(6):807

Hausselt JH, Nix WD (1977) Acta Metall 25(6):595

Tanaka K, Mori T, Nakamura T (1970) Philos Mag 21(170):267

Langdon TG, Vastava RB (1982) ASTM STP 765. ASTM, Philadelphia, p 435

Tanaka M, Iizuka H (1985) J Mater Sci 20(10):3750. doi:10.1007/BF01113784

Iizuka H, Tanaka M (1986) J Mater Sci 21(2):611. doi:10.1007/BF01145531

Koul AK, Gessinger GH (1983) Acta Metall 31(7):1061

Iizuka H, Tanaka M (1986) J Mater Sci 21(8):2803. doi:10.1007/BF00551493

Tanaka M, Miyagawa O, Sakaki T, Iizuka H, Ashihara F, Fujishiro D (1988) J Mater Sci 23(2):621. doi:10.1007/BF01174696

Hong HU, Nam SW (2002) Mater Sci Eng A 332:255

Kotval PS, Venables JD, Calder RW (1972) Metall Trans 3(2):453

Acknowledgements

The authors thank Dr. D. Fujishiro, Former Director of Nittan Valve Company, for supplying Ni–Cr alloy used in this study. They also thank Prof. Z. Nakagawa and Mr. K. Sasaki of Center for Geo-Environmental Science, Akita University for chemical analysis by SEM-EDS, and Mr. T. Moronaga of Electronics Division of Kobelco Research Institute Inc. for microstructural and chemical analyses using TEM-EDS.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tanaka, M., Kato, R. The effect of heat treatments on the creep–rupture properties of a wrought Ni–Cr heat-resistant alloy at 973 K. J Mater Sci 45, 4029–4035 (2010). https://doi.org/10.1007/s10853-010-4481-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4481-9