Abstract

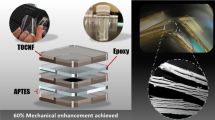

In certain application of fiber reinforced polymer composites fracture resistance is required. The aim of this study was to improve the interfacial adhesion between plain woven carbon fiber (CF) and epoxy matrix filled with microfibrillated cellulose (MFC) modified with carboxyl-terminated butadiene acrylonitrile (CTBN) as liquid rubber. CF/Epoxy/MFC/CTBN composite was characterized by different techniques, namely, tensile, bending, fracture toughness (mode I) test, and scanning electron microscope (SEM). The results reveal that at a fiber content 1% of MFC and 10% CTBN, initiation and propagation interlaminar fracture toughness in mode I improved significantly by 96 and 127%, respectively, which could be attribute to strong adhesion between filled epoxy, CF, and rubber. This can be explained by SEM at given weight as well; SEM images showed that in front of the tip, fiber breakage during initiation delimination as well as the extensive matrix deformation between fibers accounting for increase fracture toughness.

Similar content being viewed by others

References

Darder M, Aranda P, Ruiz-Hitzky E (2007) Adv Mater 19:1309

Angles MN, Dufresne A (2001) Macromolecules 34:2921

Zimmermann T, Pohler E, Geiger T (2004) Adv Eng Mater 6(9):754

Soykeabkaew N, Arimoto N, Nishino T, Peijs T (2008) Compos Sci Technol 68:2201

Iwatake A, Nogi M, Yano H (2008) Compos Sci Technol 68:2103

Abdelmouleh M, Boufi S, Belgacem MN, Dufresne A, Gandini A (2005) J Appl Polym Sci 98:974

Nakagaito AN, Yano H (2008) Cellulose 15:555

Lu J, Wang T, Drzal LT (2008) Composites A 39:738

Lu J, Askeland P, Drzal LT (2008) Polymer 49:1285

Takagaki N, Okubo K, Fujii T (2008) In: Proceedings of the sixth Asia–Australasian conference on composite materials (ACCM/6), Kumamouto, 23–26 September 2008, pp 499–501

Nakagaito AN, Yano H (2005) Appl Phys A 80(1):155

Svagan AJ, Samir MASA, Berglund LA (2007) J Polym Environ 8:2556

Suryanegara L, Nakagaito AN, Yano H (2009) Compos Sci Technol 69:1187

Todo M, Jar P-YB, Takahashi K (2000) Compos Sci Technol 60(2):263

Okubo K, Fujii T, Yamashita N (2005) JSME Int J Ser A 48(4):199

Okubo K, Fujii T, Thostenson ET (2009) Composites A 40:469

Naoya Y, Kazuya O, Fujii T (2004) Bamboo J 21:35

Mazumdar SK (2002) Composites manufacturing: materials, product, and process engineering. CRC Press LLC, USA

Thomas R, Yumei D, Yuelong H, Le Y, Moldenaers P, Weimin Y, Czigany T, Thomas S (2008) Polymer 49(1):278

Verchere D, Sautereau H, Pascault JP, Moschiar SM, Riccardi CC, Williams RJJ (1990) J Appl Polym Sci 41:467

Chen TK, Jan YH (1991) Polym Eng Sci 31(8):577

Bussi P, Ishida H (1994) J Appl Polym Sci 53(4):441

Nigam V, Setua DK, Mathur GN (1999) Polym Eng Sci 39(8):1424

Ratna D, Banthia AK (2000) Polym Int 49:281

Shukla SK, Srivastava D (2006) J Appl Polym Sci 100(3):1802

Pearson RA, Yee AF (1989) J Mater Sci 24:2571. doi:10.1007/BF01174528

Thomas R, Abraham J, Thomas S (2004) J Polym Sci B 42(13):2531

Tripathi G, Srivastava D (2007) Mater Sci Eng A 443:262

Chand S (2000) J Mater Sci 35:1303. doi:10.1023/A:1004780301489

Gabr MH, Okuba K, Elrahman MA, Fujii T (2009) Compos Struct. doi:10.1016/j.compstruct.2009.12.009

JIS K7073 (1988) Testing method for tensile properties of carbon fiber-reinforced plastics. Japanese Industrial Standard, Japanese Standards Association

JIS K 7074 (1988) Testing methods for flexural properties of carbon fiber reinforced plastics. Japanese Industrial Standard, Japanese Standards Association

JIS K 7086 (1997) Testing methods for interlaminar fracture toughness of carbon fibre reinforced plastics. Japanese Industrial Standard, Japanese Standards Association

Hodgkinson JM (2000) Mechanical testing of advanced fibre composites. CRC Press, Cambridge

Abadyan M, Khademi V, Bagheri R, Haddadpour H, Kouchakzadeh MA, Farsadi M (2009) Mater Des 30:1976

Harismendy I, Miner R, Valea A, Llano-Ponte R, Mujika F, Mondragon I (1997) Polymer 38:5573

Charlesworth JM (1988) Polym Eng Sci 28(4):230

Tripathi G, Srivast D (2007) Mater Sci Eng A 443(1–2):262

Verchere D, Pascault JP, Sautereau H, Moschiar SM, Riccardi CC, Williams RJJ (1991) J Appl Polym Sci 42(3):701

Velmurugan R, Solaimurugan S (2007) Compos Sci Technol 67(1):61

Shah Khan MZ, Mouritz AP (1996) Compos Sci Technol 56(6):695

Ray D, Sarkar BK, Bose NR (2002) Composites A 33(2):233

Gao B, Kim J-K, Leung CKY (2003) Compos Sci Technol 63:883

Jordan WM, Bradley WL (1987) In: Johnston NJ (ed) Toughened composites. ASTM special technical publication 937. ASTM, Philadelphia, pp 95–114

Wetzel B, Rosso P, Haupert F, Friedrich K (2006) Eng Fract Mech 73:2375

Faber KT, Evans AG (1983) Acta Metall 31(4):565

Faber KT, Evans AG (1983) Acta Metall 31(4):577

Barcia FL, Amaral TP, Soares BG (2003) Polymer 44(19):5811

Todo M, Jar P-YB (1998) Compos Sci Technol 58(1):105

Alif N, Carlsson LA, Boogh L (1998) Composites B 29(5):603

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gabr, M.H., Elrahman, M.A., Okubo, K. et al. Interfacial adhesion improvement of plain woven carbon fiber reinforced epoxy filled with micro-fibrillated cellulose by addition liquid rubber. J Mater Sci 45, 3841–3850 (2010). https://doi.org/10.1007/s10853-010-4439-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4439-y