Abstract

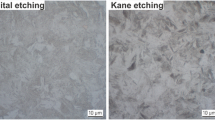

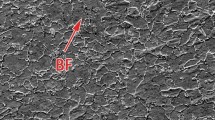

The influence of weld thermal simulation on ICGC HAZ microstructure and mechanical properties of Cu containing Nb-Ti-microalloyed steel has been investigated. Low heat input of 0.7 kJ/mm (simulated fast cooling of Δt 8/5 = 5 s) and high heat input of 4.5 kJ/mm (simulated slow cooling of Δt 8/5 = 61 s) were used to generate double-pass thermal cycles with peak temperatures of 1350 and 800 °C, respectively. The microstructure after high heat input mainly consisted of polygonal and quasi-polygonal ferrite (QF) grains with certain amount of acicular ferrite, whereas, after the low heat input, microstructure mainly consisted of lath or elongated bainite–ferrite, QF and M–A constituents. The size of ferrite grains decreased and volume of M/A constituents increased with fast cooling rate. The precipitation characteristics were found to be similar in both cooling rates. However, the precipitation of Cu-related phases was promoted by slow cooling rate. By fast cooling rate, the investigated steel exhibited an increase in hardness from 187HV to 197HV. Consequently higher yield strength with considerable loss in the (−10 °C) CTOD fracture toughness (δfast cooling = 0.86 mm and δslow cooling = 1.12 mm) were demonstrated.

Similar content being viewed by others

References

Shanmugam S, Ramisetti NK, Misra RDK, Mannering T, Panda D, Jansto S (2007) Mater Sci Eng A 460–461:335

Fang X, Fan Z, Ralph B, Evans P, Underhill R (2002) Mater Sci Tech 18:47

Thompson M, Ferry M, Manohar PA (2001) ISIJ Int 41:891

Ai JH, Zhao TC, Gao HJ, Hu YH, Xie XS (2005) J Mater Proc Tech 160:390

Pereloma EV, Bayley C, Boyd JD (1996) Mater Sci Eng A 210:16

Rak I, Gliha V, Kocak M (1997) Met Mater Trans A 28:199

Suzuki S, Weatherly GC, Houghton DC (1987) Acta Metall 35(2):341

Kanazawa S, Nahashima A, Okamoto K, Knaya K (1976) Trans Iron Steel Inst Jpn 16:486

Loberg B, Nordgren A, Strid J, Easterling K (1984) Metall Mater Trans A 15A:33

Shome M, Gupta OP, Mohanty ON (2004) Scripta Mater 50:1007

Palmiere EJ, Garcia CI, DeArdo AJ (1994) Metall Mater Trans A 25A:277

Ghosh A, Das S, Chatterjee S, Ramachandra Rao P (2006) Mater Charact 56:59

Kim BC, Lee S, Kim N, Lee DY (1991) Metall Mater Trans A 22A:139

Davis CL, King JE (1993) Mater Sci Technol 9:8

Shi Y, Hanb Z (2008) J Mater Process Tech 207(1–3):30–39

Chen Z, Lorretto MH, Cochrane RC (1987) Mater Sci Technol 3(10):836

Hrivanak I, Matsuda F, Ikeuchi K (1992) Trans JWRI 21:241

Lee HC, Koh HJ, Seo CH, Kim NJ (2008) Scripta Mater 59:83

Xue XH, Zhou X, Qian BN, Li JL, Lou SN, Shanghai J (2003) Jiao Tong University 37:1854

Aihara S, Okamoto K (1990) In: Metallurgy, welding, and qualification of microalloyed (HSLA) steel weldments, p 402

Acknowledgements

The authors are grateful to the management of POSCO for providing research materials of this investigation and for the permission to publish the article. In addition, we are in debt to the Post Doc. Fellowship program of the KOSEF, Republic of Korea, for sponsoring the visit of Dr. A.E. Amer, Cairo—Egypt at the Korea Advanced Institute of Science and Technology (KAIST)—Department of Materials Science and Engineering.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Amer, A.E., Koo, M.Y., Lee, K.H. et al. Effect of welding heat input on microstructure and mechanical properties of simulated HAZ in Cu containing microalloyed steel. J Mater Sci 45, 1248–1254 (2010). https://doi.org/10.1007/s10853-009-4074-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-4074-7