Abstract

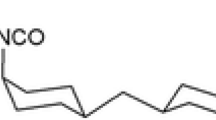

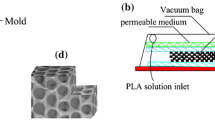

The microdomain structure of polyurethanes (PUR) determines their unique physical properties and makes polyurethanes attractive candidates for various tissue engineering applications. 3D scaffolds based on polyurethanes with different contents of hard segments were fabricated by a salt-leaching/polymer coagulation method. The process parameters were carefully considered, particularly the polymer solution concentration and characteristics of the polyurethane, which are the critical parameters for the control of porosity and pore size distribution. In this study, 3D polyurethane scaffolds were fabricated with interconnected pores and porosity from 64% to 80%. Pore size distribution was evaluated using quantitative image analysis and mercury intrusion porosimetry (MIP). The scaffolds fabricated from polyurethanes with 70 wt.% of hard-domain content were found to have the best compression properties.

Similar content being viewed by others

References

Palsson B, Hubbell JA, Plonsey R et al (2003) Tissue engineering. CRC Press, Boca Raton, Florida

Bronzino JD (2006) Tissue engineering and artificial organs. CRC Press, Boca Raton, Florida

Oh SH, Park IK, Kim JM et al (2007) Biomaterials 28:1664

Zhang Z, Wang Z, Liu S et al (2004) Biomaterials 25:177

Wei HJ, Liang H Ch, Lee MH et al (2005) Biomaterials 26:1905–1913

Whang K, Healy KE, Elenz DR et al (1999) Tissue Eng 5:35

Lu JX, Flautre B, Anselme K (1999) J Mater Sci Mater Med 10:111

Karageorgiou V, Kaplan D (2005) Biomaterials 26:5474

Hutmacher DW (2000) Biomaterials 21:2529

Zhang J, Zhang H, Wu L, Ding J (2006) J Mater Sci 41:1725. doi:https://doi.org/10.1007/s10853-006-2873-7

Draghi L, Resta S, Pirozzolo MG, Tanzi MC (2005) J Mater Sci Mater Med 16:1093

Chen G, Ushida T, Tateishi T (2001) Mater Sci Eng C 17:63

Mikos AG, Thorsen AJ, Czerwonka LA et al (1994) Polymer 35(5):1068

Van Tienen TG, Heijkants RGJC, Buma P et al (2002) Biomaterials 23:1731

Hou Q, Grijpma DW, Feijen J (2003) Biomaterials 24:1937

Kim SS, Park MS, Jeon O et al (2006) Biomaterials 27:1399

Hentze HP, Antonietti M (2002) Rev Mol Biotechnol 90:27

Lamba NMK, Woodhouse KA, Cooper SL (1997) Polyurethanes in biomedical applications. CRC Press, New York

Chen KS, Leon Yu T, Chen YS et al (2001) J Polym Res 82:99

Sanchez-Adsuar MS (2000) Int J Adhes Adhes 20:291

Ioan S, Grigorescu G (2002) Eur Polym J 38:2295

Tang YW, Labow RS, Santerre JP (2001) J Biomed Mater Res (2001) 56(4):516

Takahara A, Tashita J, Kajiyama T et al (1985) J Biomed Mater Res 19:13

Guan J, Fujimoto KL, Sacksa MS, Wagner WR (2005) Biomaterials 26:3961

Riboldi SA, Sampaolesi M, Neuenschwander P, Cossu G, Mantero S (2005) Biomaterials 26:4606

Grad S, Kupcsik L, Gorna K et al (2003) Biomaterials 24:5163

Zhang J, Doll BA, Beckman EJ et al (2003) J Biomed Mater Res 67A:389

Groot JH, Nijenhuis AJ, Bruin P et al (1990) Colloid Polym Sci 268:1073

Wojnar L, Kurzydłowski KJ, Szala J (2002) Praktyka analizy obrazu Polskie Towarzystwo Steorologiczne, Kraków

Ho ST, Hutmacher DW (2006) Biomaterials 27:1362

Hou Q, Grijpma DW, Feijen J (2003) Biomaterials 24:1937–1947

Heijkants RGJC, van Tienen TG, de Groot JH et al (2006) J Mater Sci 41:2423. doi:https://doi.org/10.1007/s10853-006-7065-y

Lee HK, Kimb JY, Kimb YD, Shinb JY, Kimb SC (2001) Polymer 42:3893

Nam YS, Park TG (1999) Biomaterials 20:1783

Hacker M, Ringhofer M, Appel B et al (2007) Biomaterials 28:3497

Reignier J, Huneault MA (2006) Polymer 47:4703

Acknowledgements

This scientific work was financially supported by the Ministry of Science and Higher Education, grant R1301901. The authors wish to thank Professor Andrzej Dworak and Dr. Barbara Trzebicka of Centre of Polymer and Carbon Materials Polish Academy of Sciences for the GPC measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bil, M., Ryszkowska, J. & Kurzydłowski, K.J. Effect of polyurethane composition and the fabrication process on scaffold properties. J Mater Sci 44, 1469–1476 (2009). https://doi.org/10.1007/s10853-008-3037-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-3037-8