Abstract

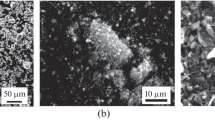

Si3N4-barium aluminum silicate (BAS) self-reinforced composites have been prepared by pressureless sintering at 1800 °C for 2 h. The β-Si3N4 seeds incorporated in the starting α-Si3N4 powders encouraged the α- to β-Si3N4 phase transformation, and the final bimodal microstructure with large grains, consequently, led to the improvement of the fracture toughness, from 7.74 to 8.34 MPa m1/2. The almost-complete crystallized BAS benefited the high-temperature mechanical properties. The residual stress, crack deflection, grain bridging, and pullout were considered as the major toughening mechanisms in this composite.

Similar content being viewed by others

References

Riley FL (2000) J Am Ceram Soc 83:245

Sajglik P, Dusza J, Hoffmann MJ (1995) J Am Ceram Soc 78:2619. doi:https://doi.org/10.1111/j.1151-2916.1995.tb08031.x

Liu HH, Huang JL (2001) Ceram Int 27:621. doi:https://doi.org/10.1016/S0272-8842(01)00008-6

Hayashi T, Munakata H, Suzuki H, Saito H (1986) J Mater Sci 71:3501. doi:https://doi.org/10.1007/BF02402994

Drummond CH, Lee WE, Bansal NP, Hyatt MJ (1989) Ceram Eng Sci Proc 10:1485. doi:https://doi.org/10.1002/9780470310588.ch64

Bandyopadhyay A, Aswarth PB (1995) Mater Res 10:3143. doi:https://doi.org/10.1557/JMR.1995.3143

Jang HM, Kim KS, Jung CJ (1992) J Am Ceram Soc 75:2883. doi:https://doi.org/10.1111/j.1151-2916.1992.tb05524.x

Ye F, Zhou Y, Lei TC, Yang JM, Zhang LT (2001) J Mater Sci 36:237. doi:https://doi.org/10.1023/A:1004830229429

Pickup H, Brook RJ (1987) Br Ceram Proc 39:69

Pickup H, Brook RJ (1986) In: Bunk W, Hausner H (eds) Proc 2nd Int Symp Ceramic Materials and components for Engines, p 93

Freitag DW (1995) Mater Sci Eng A 195:197. doi:https://doi.org/10.1016/0921-5093(94)06519-5

Bandyopadhyay A, Aswath PB, Porter W, Cavin OB (1995) J Mater Res 10:1256. doi:https://doi.org/10.1557/JMR.1995.1256

Bandyopadhyay A, Quander SW, Aswath PB, Freitag DW, Richardson KK, Hunn DL (1995) Scr Metall Mater 72:1417. doi:https://doi.org/10.1016/0956-716X(95)00181-T

Richardson KK, Freitag DW, Hunn DL (1995) J Am Ceram Soc 72:2662. doi:https://doi.org/10.1111/j.1151-2916.1995.tb08037.x

Hwang CJ, Newman RA (1996) J Mater Sci 31:150. doi:https://doi.org/10.1007/BF00355139

Drummond Ch (1990) J Non-Cryst Solid 123:114

Fang Y, Yu F, White KW (2000) J Mater Sci 35:2695. doi:https://doi.org/10.1023/A:1004749825368

Kanzaki S, Brito ME, Valecillos MC, Hirao K, Toriyama M (1997) J Eur Ceram Soc 17:1841. doi:https://doi.org/10.1016/S0955-2219(97)00081-2

Hirosaki N, Akimune Y, Mitomo M (1994) J Am Ceram Soc 77:1093. doi:https://doi.org/10.1111/j.1151-2916.1994.tb07277.x

Becher PF (1991) J Am Ceram Soc 74:255. doi:https://doi.org/10.1111/j.1151-2916.1991.tb06872.x

Hirao K, Nagaoka T, Brito ME, Kanzaki S (1996) J Ceram Soc Jpn 104:54

Becher PF, Sun EY, Plucknett KP, Alexander KB, Hsueh CH, Lin HT et al (1998) J Am Ceram Soc 81:2831

Quander SW, Bandyopadhyay A, Aswarth PB (1997) J Mater Sci 32:2021. doi:https://doi.org/10.1023/A:1018554217839

Horng HL, Jow LH (2002) J Am Ceram Soc 89:2331

Hirao K, Ohashi M, Brito ME, Kanzaki S (1995) J Am Ceram Soc 78:1687. doi:https://doi.org/10.1111/j.1151-2916.1995.tb08871.x

Jais US, Lee WE, James PF (1999) J Am Ceram Soc 82:3200

Becher PF, Sun EY, Plucknett KP, Alexander KB, Hsueh CH, Lin HT et al (1998) J Am Ceram Soc 81:2821

Wang CM, Pan XQ, Ruhle M, Riley FL, Mitomo M (1996) J Mater Sci 31:5281. doi:https://doi.org/10.1007/BF01159294

Horng HL, Jow LH (2001) J Am Ceram Soc 84:1891

Ye F, Chen S, Iwasa M (2003) Scr Mater 48:1433. doi:https://doi.org/10.1016/S1359-6462(03)00083-6

Ziegler G, Heinrich J, Wotting G (1987) J Mater Sci 22:3041. doi:https://doi.org/10.1007/BF01161167

Taya M, Hayashi S, Kobayashi AS, Yoon HS (1990) J Am Ceram Soc 73:1382. doi:https://doi.org/10.1111/j.1151-2916.1990.tb05209.x

Acknowledgement

The authors wish to express thanks the financial support of the State Education Ministry of the People’s Republic of China (RFDP Program (20060698008)).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, B., Yang, J., Guo, R. et al. Microstructure and property enhancement of silicon nitride-barium aluminum silicate composites with β-Si3N4 seed addition. J Mater Sci 44, 1351–1356 (2009). https://doi.org/10.1007/s10853-008-3009-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-3009-z