Abstract

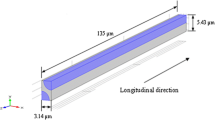

This paper describes mechanism-based modeling of damage evolution in high temperature polymer matrix composites (HTPMC) under thermo-oxidative aging conditions. Specifically, a multi-scale model based on micro-mechanics analysis in conjunction with continuum damage mechanics (CDM) is developed to simulate the accelerated fiber–matrix debond growth in the longitudinal direction of a unidirectional HTPMC. Using this approach, one can relate the behavior of composites at the micro-level (representative volume element) to the macro-level (structural element) in a computationally tractable manner. Thermo-oxidative aging is simulated with diffusion-reaction model in which temperature, oxygen concentration, and weight loss effects are considered. For debond growth simulation, a model based on Darcy’s laws for oxygen permeation in the fiber–matrix interface is employed, that, when coupled with polymer shrinkage, provides a mechanism for permeation-controlled debond growth in HTPMC. Benchmark of model prediction with experimental observations of oxidation layer growth is presented, together with a laminate thermo-oxidative life prediction model based on CDM to demonstrate proof-of-concept.

Similar content being viewed by others

References

Colin X, Verdu J (2005) Compos Sci Technol 65:411. doi:https://doi.org/10.1016/j.compscitech.2004.09.011

Colin X, Marais C, Verdu J (2005) Compos Sci Technol 65:117. doi:https://doi.org/10.1016/j.compscitech.2004.06.009

Tandon GP, Pochiraju KV, Schoeppner GA (2006) Polym Degrad Stab 91(8):1861. doi:https://doi.org/10.1016/j.polymdegradstab.2005.11.008

Pochiraju KV, Tandon GP (2006) J Eng Mater Technol 128:107. doi:https://doi.org/10.1115/1.2128427

Pochiraju KV, Tandon GP, Schoeppner GA (2008) Mech Time-Depend Mater 12:45. doi:https://doi.org/10.1007/s11043-007-9042-5

Wang SS, Chen X (2006) J Eng Mater Technol 128:81. doi:https://doi.org/10.1115/1.2132377

Talreja R (1991) Mech Mater 12:165. doi:https://doi.org/10.1016/0167-6636(91)90061-4

Talreja R (2006) J Mater Sci 41:6800. doi:https://doi.org/10.1007/s10853-006-0210-9

Crank J (1975) Mathematics of diffusion, 2nd edn. Clarendon Press, Oxford

Roy S, Wang Y, Park S, Liechti KM (2006) ASME J Eng Mater Technol 128(1):11. doi:https://doi.org/10.1115/1.2127959

Roy S, Wang Y, Park S, Xu D, Liechti KM (2007) J Mech Adv Mater Struct 14:1. doi:https://doi.org/10.1080/15376490600985227

Needleman A (1987) J Appl Mech 54:525

Wise J, Gillen KT, Clough RL (1997) Polymer 38:1929. doi:https://doi.org/10.1016/S0032-3861(96)00716-1

Williams JG (1984) Fracture mechanics of polymers. Ellis Horwood Limited

Coleman BD, Gurtin ME (1967) J Chem Phys 47:597

Smith GF (1982) Quart Appl Math 39:509

ABAQUS, Version 6.5 (2004) Hibbit, Karlsson, and Sorensen Inc., Providence, Rhode Island

Acknowledgements

The authors gratefully acknowledge the support of the Mechanics of Multifunctional Materials & Microsystems Program of the Air Force Office of Scientific Research, with Dr. Byung “Les” Lee as Program Manager.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Roy, S., Singh, S. & Schoeppner, G.A. Modeling of evolving damage in high temperature polymer matrix composites subjected to thermal oxidation. J Mater Sci 43, 6651–6660 (2008). https://doi.org/10.1007/s10853-008-2691-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2691-1