Abstract

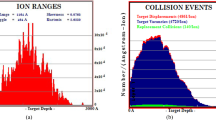

We have studied the effects of nitrogen pre-implantation of AISI C1045 steel substrates on the microstructure and microhardness of deposited TiN coatings. The substrates were implanted at 40 keV, to the fluences from 5 × 1016 to 5 × 1017 ions/cm2, which was followed by deposition of 1.3-μm thick TiN coatings by reactive sputtering. Structural characterization of the samples was performed by standard and grazing incidence X-ray diffraction analysis, Rutherford backscattering spectroscopy and transmission electron microscopy. Microhardness was measured by the Vicker’s method. Nitrogen implantation up to 2 × 1017 ions/cm2 induces the formation of Fe2N phase in the near surface region of the substrates, which becomes more pronounced for higher fluences. Microstructure of the deposited TiN coatings shows a strong dependence on ion beam pre-treatment of the substrates. The layers grown on non-implanted substrates have a (200) TiN preferential orientation, and those grown on implanted substrates have (111) TiN preferential orientation. The change in preferred orientation of the layers is assigned to a developed surface topography of the substrates induced by ion implantation, and possible effects of distorted and altered crystalline structure at the surface. Ion implantation and deposition of TiN coatings induce an increase of microhardness of this low performance steel for more than eight times.

Similar content being viewed by others

References

Sundgren JE (1985) Thin Solid Films 128:21

Zeghni AE, Hashmi MSJ (2004) J Mat Proc Technol 155–156:1918

Sun Y, Bell T (1993) Wear 166:119

Van Stappen M, Kerkhofs M, Qaeyhaegens C, Stals L (1992) Wear 153:655

Hock K, Spies HJ, Larich B, Leonhardt G (1996) Surf Coat Technol 88:44

Canu E, Martinez L, Simancas J, Perez-Trujillo FJ, Gomez C, Bastidas JM (2006) Surf Coat Technol 200:5123

Sharkeev YP, Bull SJ, Perry AJ, Klingenberg ML, Fortuna SV, Michler M, Manory RR, Shulepov IA (2006) Surf Coat Technol 200:5915

Jones AM, Bull SJ (1996) Surf Coat Technol 83:269

Intarasiri S, Yu LD, Chudoba T, Reuther H, Ramelt U, Richter E (1998) Surf Coat Technol 99:305

Kukareko VA, Byeli AV (2000) Surf Coat Technol 127:174

Ziegler JF, Biersack JP, Littmark U (1985) The stopping and range of ions in Solids. Pergamon Press, New York

Barradas NP, Jeynes C, Webb RP (1997) Appl Phys Lett 71:291

Kopcewicz M, Jagielski J, Matz W (2002) Hyperfine Interact 139/140:369

Škorić B, Kakaš D, Rakita M, Bibić N, Peruško D (2004) Vacuum 76:169

Peruško D, Popović M, Novaković M, Bibić N (2005) In: Popović Z, Maričić AM (eds) Proceedings of VI Scientific Meeting: Physics and Technology of Materials, Čačak, Serbia, August 2005. Technical Faculty of Čačak p 31

Wong-Ng W, Mcmurdie H, Paretzkin B, Hubbard C, Dragoo A (1987) NBS, Gaithersburg, MD, USA, ICDD Grant-in-Aid

Klung HP, Alexander LE (1974) In: X-ray diffraction procedures, Chap. 7. J. Willey & Sons

Youssef AA, Budzynski P, Feliks J, Kobzev AP, Sielanko J (2004) Vacuum 77:37

Acknowledgements

The authors gratefully acknowledge Prof H. Hofsaess for enabling RBS analysis at Goettingen University. This work was supported by the Ministry of Science and Environmental Protection of the Republic of Serbia (Project No. OI 141013) and partially by the International Atomic Energy Agency, Vienna.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Peruško, D., Mitrić, M., Milinović, V. et al. The effects of pre-implantation of steel substrates on the structural properties of TiN coatings. J Mater Sci 43, 2625–2630 (2008). https://doi.org/10.1007/s10853-008-2477-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2477-5