Abstract

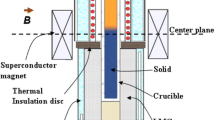

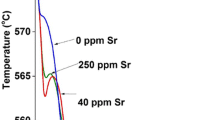

In order to investigate the effects of high magnetic fields on the as-solidified structures of Al alloys, solidification experiments of hypoeutectic and hypereutectic Al–Si alloys under various high magnetic field conditions (up to 12 T) have been conducted. It was found that uniform magnetic fields and gradient magnetic fields affect the solidification process by Lorentz force and magnetization force, respectively. The primary silicon crystals of hypereutectic Al–Si alloys are distributed, relatively, homogeneously under uniform magnetic fields, whereas they congregate near the top surface or bottom of samples by the combined action of buoyancy and magnetization force under gradient magnetic fields. The results indicate that it is possible to control the behaviors of reinforced particles in the metal matrix and improve the material performances by using high magnetic fields in the solidification process of metal matrix composites. The experiments also showed that high magnetic fields decrease the interlamellar spacing of the eutectic structure, while there exists a certain optimum value of magnetic intensity corresponding to the minimum value of interlamellar spacing, and magnetic energy is capable of influencing thermodynamic equilibrium of solidifying system and makes the content of eutectic aluminum in eutectic structures increased.

Similar content being viewed by others

References

Asai S (2003) In: Asai S, Fautrelle Y, Gillon P, Durand F (eds) Proceedings of the 4th International Conference on Electromagnetic Processing of Materials, Lyon, The Company Forum Edition, Lyon, p 1

Asai S (2000) Sci Technol Adv Mater 1:191

Jones TB (1979) J Appl Phys 50:5057

Garcia A, Moron C, Maganto F (2003) Sensor Actuat A-Phys 106:108

Negrini F, Fabbri M, Zuccarini M, Takeuchi E (2000) Energy Convers Manage 41:1687

Asai S (2004) Model Simul Mater Sci Eng 12:R1

Asai S, Sassa K, Tahashi M (2003) Sci Technol Adv Mater 4:455

Schneider-Muntau HJ, Brandt BL, Brunel LC, Cross TA, Edison AS, Marshall AG, Reyes AP (2004) Physica B 346–347:643

Perenboom JAAJ, Wiegers SAJ, Christianen PCM, Zeitler U, Maan JC (2004) Physica B 346–347:659

Kang JY, Tozawa S (1996) Acta Phys Sin 45:324

Wang Q, Wang CJ, Wang EG, He JC (2005) Acta Metall Sin (in Chinese) 41:128

Wang H, Ren ZM, Deng K, Xu KD (2002) Acta Metall Sin (in Chinese) 38:41

Morikawa H, Sassa K, Asai S (1998) Mater Trans JIM 39:814

Yasuda H, Ohnaka I, Ninomiya Y, Ishii R, Fujita S, Kishio K (2003) In: Asai S, Fautrelle Y, Gillon P, Durand F (eds) Proceedings of the 4th International Conference on Electromagnetic Processing of Materials, Lyon, The Company Forum Edition, Lyon, p 459

Nakada M, Mori K, Nishioka S, Tsutsimi H (1997) ISIJ Int 37:358

Yasuda H, Ohnaka I, Kawakami O, Ueno K, Kishio K (2003) ISIJ Int 43:942

Wang Q, Wang EG, He JC, Hu K, Takahashi K, Watanabe K (2003) In Asai S, Fautrelle Y, Gillon P, Durand F (eds) Proceedings of the 4th International Conference on Electromagnetic Processing of Materials, Lyon, The Company Forum Edition, Lyon, p 464

Wang Q, Wang CJ, Pang XJ, He JC (2004) Chinese J Mater Res (in Chinese) 18:568

Ikezoe Y, Kaihatsu T, Uetake H, Hirota N, Nakagawa J, Kitazana K (2000) Trans Mater Res Soc Jpn 25:77

Robert C (1982–1983) In: CRC Handbook of Chemistry and Physics (the 63rd edition), CRC Press, Inc., Florida, p B-244

The Japan Institute of Metals (1993) In: Data handbook of metals (the Third Edition, in Japanese), Maruzen Co. Ltd, Shizuoka, p 18

Acknowledgement

This work was supported by the National Natural Science Foundation of China (Grant No. 50374027), the Program for New Century Excellent Talents in University (Grant No. NCET-06-0289) and the 111 project (Grant No. B07015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Q., Wang, Cj., Liu, T. et al. Control of solidified structures in aluminum–silicon alloys by high magnetic fields. J Mater Sci 42, 10000–10006 (2007). https://doi.org/10.1007/s10853-007-2050-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-2050-7