Abstract

An optimised structure is one which uses the smallest quantity of the best material to perform its function, with adequate safety factor or margin for error. Structural optimisation occurs not only in mechanical engineering, but also in nature: plants with hollow stems or stalks gain a height advantage, and are thus more efficient, by approaching the optimum shape. Here we consider the optimisation of orthotropic tubes, typifying, in a mechanical sense, stalk and stem. The stiffness and strength of orthotropic tubes of initially circular section are reviewed, and diagrams are proposed which allow the optimum section shape to be selected.

Similar content being viewed by others

References

Amada S, Munekata T, Nagase Y, Ichikawa Y, Kirigai A, Yang ZF (1996) J Comp Mat 30:800

Arce-Villalobos OA (1993) Fundamentals of the design of bamboo structures. PhD Thesis, Eindhoven University of Technology, Netherlands

Niklas KJ (1989) Am J Bot 76:521

Niklas KJ (1992) Plant biomechanics: an engineering approach to plant form and function. University of Chicago Press, Chicago

Niklas KJ (1995) Ann Bot 75:133

Niklas KJ (1997a) Ann Bot 80:275

Niklas KJ (1997b) Ann Bot 80:437

Niklas KJ (1998) Ann Bot 81:11

Spatz HC, Speck T, Vogellehner D (1990) Bot Acta 103:123

Spatz HC, Boomgaarden C, Speck T (1993) Bot Acta 106:254

Spatz HC, Speck T (1994) Biomimetics 2:149

Spatz HC, Kohler L, Speck T (1998) Am J Bot 85:305

Speck T, Speck O, Emanns A, Spatz HC (1998) Bot Acta 111:366

Schulgasser K, Witztum A (1997) Ann Bot 80:35

Cecchini LS, Weaver PM (2002) AIAA J 40:2136

Corona E, Rodrigues A (1995) Comp Eng 5:163

Fabian O (1977) Int J Sol Struct 13:1257

Gerard G (1968) Minimum weight design of compressive structures. New York University Press/Interscience, New York

Harursampath D, Hodges DH (1999) Int J Non-Linear Mech 34:1003

Kedward KT (1978) In: Proceedings of the 2nd international conference on composite materials (ICCM/2). Met Soc of AIME p 353

Libai A, Bert CW (1994a) Int J Sol Struct 31:1003

Libai A, Bert CW (1994b) Int J Sol Struct 31:1019

NASA (1968) Space vehicles design criteria (structures)—buckling of thin-walled circular cylinders. Technical Report NASA SP-8007, NASA

Tatting BF, Gürdal Z, Vasiliev VV (1996) AIAA J 34:1934

Tatting BF, Gürdal Z, Vasiliev VV (1997) Int J Solids Struct 34:1419

Tsai SW, Wu EM (1971) J Comp Mater 5:58

Schulgasser K, Witztum A (1992) J Theor Biol 155:497

Brazier LG (1927) Proc Roy Soc Lond A 116:104

Calladine CR (1983) Theory of shell structures. Cambridge University Press, Cambridge

Ghavami K (1990) In: Ramanuja Rao I, Gnanaharan R, Sastry C (eds) Proceedings of the international bamboo workshop held in Cochin, India, 14–18 November. The Kerala Forest Research Institute, India and International Development Research Centre, Canada, p 235

Li S, Fu S, Zeng Q, Zhao X, Zhou B (1994) Biomimetics 2:15

Oda J (1980) Trans Japan Soc Mech Eng Ser A 46:997

Ueda K (1980) Res Bull Coll Exp For Hokkaido University 37:817

Akselrad EL (1965) Izv Akad Nauk USSR, Otdelenie Teknicheskikh Nauk Mech No 4:123

Seide P, Weingarten V (1961) J Appl Mech 28:112

Suo Z (1990a) J Appl Mech 57:627

Suo Z (1990b) Proc R Soc Lond A 427:331

Wegst UGK, Ashby MF (2004) Phil Mag 84:2167

Karam GN, Gibson JL (1995a) Int J Sol Struct 32:1259

Karam GN, Gibson JL (1995b) Int J Sol Struct 32:1285

Young WC (1989) Roark’s formulas for stress and strain, 6th edn. McGraw-Hill, London

Mosbrugger V (1990) The tree habit in land plants. Lecture notes in Earth Sciences: 28. Springer, Berlin

Liese W (1985) Bamboos: biology, silvics, properties, utilization (Schriftenreihe der GTZ, Nr. 180, Deutsche Gesellschaft für Technische Zusammenarbeit (GTZ) GmbH, Dag-Hammerskjöld-Weg 1+2, D-65760 Eschborn, Germany)

Acknowledgements

The ideas presented here have been helped by discussions with numerous colleagues and associates. We particularly wish to acknowledge the inputs and suggestions of Prof. C.R. Calladine, Dr. H. R. Shercliff, Dr. P. M. Weaver and of an anonymous reviewer. We also wish to acknowledge the support of the Royal Society of London and the US Advance Research Project Agency through the University Research Initiative under Office of Naval Research Contract No. N-00014092-J-1808.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1 full solution for ϕA

The transition from fracture/yield to splitting is found by equating the respective moments of failure at A:

with

Appendix 2 failure through inadequate stiffness

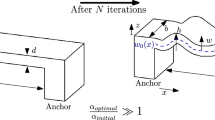

The final criterion for the macroscopical mechanical performance is that of stiffness. Mosbrugger [42] classifies plants according to their structural behaviour: either the plant is a ’flexibility strategist’ and reduces external loads by bending or it is a ’stability strategist’ and has a structure which is stiff and strong enough to withstand the loads without much bending. As the principal load is that due to wind and the velocity of wind increases with height above ground, a flexible tree which bends in a strong wind reduces the moment arm of the net wind force, especially if elastic deformation of its crown reduces its down-wind profile. Tree trunks are frequently stability strategists, whereas their branches must be capable of bending to a quarter-circle. The curvature of the bamboo culm, C, can then be expressed as a function of the length, l, of the stem

Substituting this expression for C in Eq. 8 and inserting the result for c in Eq. 13b gives the bending moment, M, which bends the stem into a quarter-circle

The second expression in the square bracket is very small due to the high slenderness ratios of bamboo (ϕ = l/r = 550−1000, [43]) and may therefore be neglected. The moment which bends a stem to a quarter-circle may therefore be rewritten as

If the plant is to function as a flexibility strategist, it must be able to do this without failing by any of the other three mechanisms analysed above.

Rights and permissions

About this article

Cite this article

Wegst, U.G.K., Ashby, M.F. The structural efficiency of orthotropic stalks, stems and tubes. J Mater Sci 42, 9005–9014 (2007). https://doi.org/10.1007/s10853-007-1936-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-1936-8