Abstract

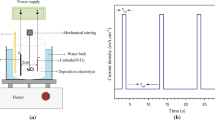

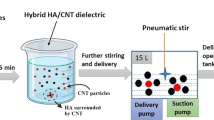

In this paper, an electrochemical (EC) method to activate 316L stainless steel (denoted as 316L) surface for biomimetic calcium phosphate (Ca–P) coatings was reported. After EC treatment, a gel-like Ca–P film with a thickness of 150 nm was generated on the stainless steel surface after treatment, which was composed of amorphous phase of calcium phosphate with a large number of crystal nuclei of octacalcium phosphate (OCP) inside. This Ca–P thin film is the main factor that causes Ca–P formation under biomimetic condition. The effectiveness of EC treatment was also compared with alkali heat (AH) pretreatment in producing biomimetic coating on 316L. A uniform Ca–P coating formed on EC treated samples after samples were immersed in saturated calcium solution (SCS) for several hours, while only some island-like deposits were found on the sample surface with AH treatment followed by immersion in SCS for several days. This work has explored a novel and effective pretreatment method to activate 316L implant surface, which can be expected to be applied to activate other metal implants.

Similar content being viewed by others

Reference

Sivakumar M, Rajeswari S, Thulasiraman V (1996) J Mater Sci Lett 15:2192

Gibbons DF (1982) Materials for orthopedic joint prosthesis. CRC Press, Boca Raton (FL), p 116

Jacobs JJ, Gilbert JL, Urban RM (1998) J Bone Joint Surg 80A:268

de Groot K, Geesink R, Klein CPAT, Serekian P (1987) J Biomed Mater Res 21:1375

Liu DM, Chou HM, Wu JD (1994) J Mater Sci Mater Med 5:147

Geesink RGT (1990) Clin Orthop 261:39

Shirkhanzadeh M (1998) J Mater Sci: Mater Med 9:67

Ban S, Maruno S (1998) Biomaterials 19:1245

Manso M, Jimenez C, Morant C, Herrero P, Martinez-Duart JM (2000) Biomaterials 21:1755

Sridhar TM, Mudali UK, Subbaiyan M (2003) Corrosion Sci 45:237

Kannan S, Balamurugan A, Rajeswari S (2003) Mater Lett 57:2382

Sridhar TM, Mudali UK, Subbaiyan M (2003) Corrosion Sci 45:2337

Cotell CM (1993) Appl Surf Sci 69:140

Liu DM, Yang Q, Trocaynski T (2002) Biomaterials 23:691

Gross KA, Chai CS, Kannangara GSK, Bin-Nissan B, Hanley L (1998) J Mater Sci Mater Med 9:834

Liu DM, Troczynski T, Tseng WJ (2001) Biomaterials 21:1721

Jonasova L, Muller FA, Helebrant A, Strnad J, Greil P (2004) Biomaterials 25:1187

Kim H-M, Miyaji F, Kokubo T, Nishiguchi S, Nakamura T (1999) J Biomed Mater Res 45:100

Barrere F, van Blitterswijk CA, de Groot K, Layrolle P (2002) Biomaterials 23:2211

Li P, Ducheyne P (1998) J Biomed Mater Res 41:341

Lin FH, Hsu YS, Lin SH, Sun JS (2002) Biomaterials 23:4029

Habibovic P, Barrere F, Blitterswijk CA, de Groot K, Layrolle P (2002) J Am Ceram Soc 85:517

Kim HM, Miyaji F, Kokubo T, Nakamura T (1997) J Mater Sci Mater Med 8:341

Wen HB, de Wijin JR, Cui FZ, de Groot K (1998) Biomaterials 19:215

Wen HB, Liu Q, de Wijin JR, de Groot K, Cui FZ (1998) J Mater Sci Mater Med 9:121

Kim HM, Miyaji F, Kokubo T, Nakamura T (1996) J Biomed Mater Res 32:409

Zhang Q, Leng Y (2005) Biomaterials 26:3853

Eanes ED (2001) In: Chow LC, Eanes ED (eds) Octacalcium phosphate. Monagr Oral Sci V 18, Basel, Karger, New York, pp 130–147

Lu X, Leng Y (2005) Biomaterials 26:1097

Acknowledgements

This work was financially supported by Natural Science Foundation of China (C010515/30500126), and Research Grants Council of Hong Kong (No. HKUST 6037/02E). The characterization of the samples was conducted in the Materials Characterization & Preparation Facility of the Hong Kong University of Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Q., Leng, Y., Xin, R. et al. An effective approach to activate 316L stainless steel for biomimetic coating of calcium phosphate: electrochemical pretreatment. J Mater Sci 42, 6205–6211 (2007). https://doi.org/10.1007/s10853-006-1121-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-1121-5