Abstract

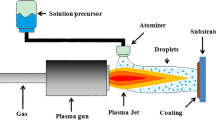

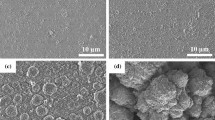

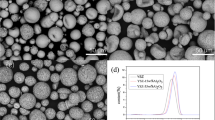

Yttria stabilized zirconia (7YSZ) solution precursor has been successfully used in the deposition of high durability thermal barrier coatings. In this paper, the thermal and crystallization behaviors of 7YSZ precursor were investigated by TG-DTA, FTIR and XRD. The results show that the precursor decomposition and crystallization temperatures greatly depend on heating rate e. g. 74°C for the crystallization temperature when tripping the heating rate. With a 10 °C/min heating rate, the weight loss due to precursor pyrolysis occurs predominantly at temperatures below 500 °C. A small weight loss due to the oxidation of residual carbon is detected from 800 °C to 950 °C. The complete crystallization of the tetragonal phase was determined to be around 500 °C by DTA and XRD analyses with a 10 °C/min heating rate. The crystallization kinetics and the activation energy of amorphous 7YSZ precursor were investigated by variable heating rate DTA. The calculated activation energy is 66.2 kJ/mol. The Avrami parameter value was determined to be 2.68, which indicates that crystallization nucleation and growth is diffusion-controlled. The crystalline phase of 7YSZ coatings deposited by the Solution Precursor Plasma Spray process was identified by XRD and Raman spectrum. The average YSZ grain size in the SPPS coating was determined to be 61 nm.

Similar content being viewed by others

References

Padture NP, Gell M, Jordan EH (2002) Science 296(5566):280

Padture NP et al (2001) Acta Mater 49(12):2251

Jadhav A et al (2005) Mater Sci Eng A-Struct 405(1–2):313

Gell M et al (2004) Surf Coat Tech 177:97

Bhatia T et al (2002) J Mater Res 17(9):2363

Xie LD et al (2003) Mater Sci Eng A-Struct 362(1–2):204

Xie LD et al (2004) Surf Coat Technol 177:103

Klug HP, Alexander LE (1954) X-ray diffraction procedures for polycrystalline and amorphous materials. Wiley, New York

Yashima M et al (1997) J Mater Res 12(10):2575

Geiculescu A, Spencer H (2000) J Sol-Gel Sci Tech 17(1):25

Balmer ML, Lange FF, Levi CG (1992) J Am Ceram Soc 75(4):946

Bansal NP, Hyatt MJ (1989) J Mater Res 4(5):1257

Padture NP, Pye LD (1991) J Mater Sci Lett 10(5):269

Yung SW, Shih PY, Chin TS (1998) Mater Chem Phys 57(2):111

Anilkumar GM, Sung YM (2003) J Mater Sci 38(7):1391; DOI 10.1023/A: 1022939624043

Hu Y, Huang CL (2000) J Non-Cryst Solids 278(1–3):170

Semenov S, Cetegen B (2001) J ThermSpray Tech 10(2):326

Yashima M et al (1993) J Appl Phys 74(12):7603

Acknowledgements

This work is supported by U.S. Office of Naval Research under Grant No. N00014-02-1-0171 managed by Drs. Lawrence Kabacoff and Steven Fishman.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, D., Jordan, E. & Gell, M. Thermal and crystallization behavior of zirconia precursor used in the solution precursor plasma spray process. J Mater Sci 42, 5576–5580 (2007). https://doi.org/10.1007/s10853-006-0976-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0976-9