Abstract:

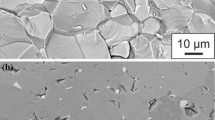

Sessile drop wetting experiments of liquid Al on polycrystalline rutile (TiO2) were conducted in the 973.1273 K temperature range under a low total pressure (9.3 10.3 Pa, Ar) and a low oxygen partial pressure (Ŝ 1.33 10.7 Pa), as a function of temperature and time. A non-wetting (150., 973 K, t >120 min.) to partial wetting (85., 1273 K, 50.60 min.) transition reflects reactive wetting characteristics. Microstructural investigations of the metal-ceramic interface shows that TiO2 is reduced by liquid Al, resulting in the formation of Al2O3. The steady-state contact angle at 1273 K of Al on α-Al2O3 and Al on rutile are very similar, and the role of Ti segregation is minimal. It appears that spreading of the Al drop on TiO2 is governed by the reduction reaction at the solid-liquid interface. The measured activation energy corresponds well to the activation energy for volume diffusion of Al, Ti and O in rutile and the volume diffusion of Al in polycrystalline α-Al2O3.

Similar content being viewed by others

References

N. Eustathopoulos, M. G. Nicholas and B. Drevet, “Wettability at High Temperatures” (Pergamon, 1999).

F. Delannay, L. Froyen and A. Deruyttere, J. Mater. Sci. 22(1) (1987) 1.

C. Garcia-Cordovilla, E. Louis and J. Narciso, Acta Mater. 47(18) (1999) 4461.

G. Levi and W. D. Kaplan, Acta Mater. 50(1) (2002) 75.

O. Dezellus, F. Hodaj and N. Eustathopoulos, J. Eur. Ceram. Soc. 23(15) (2003) 2797.

N. Eustathopoulos, Acta Mater. 46(7) (1998) 2319.

S. Wernick, R. Pinner and P. G. Sheasby, “The Surface Treatments and Finishing of Aluminium and Its Alloys,” ASM International, 5th ed., (1987). Vol. 1, p. 5.

V. Laurent, D. Chatain, C. Chatillon and N. Eustathopoulos, Acta Metall. 36(7) (1988) 1797.

C. F. Feng and L. Froyen, Composites A 31A(4) (2000) 385.

J. L. Muarray (Ed.), “Phase Diagrams of Binary Titanium Alloys,” ASM international Metal Park (1987) p. 211.

E. Saiz, R. M. Cannon and A. P. Tomsia, Acta Mater. 48(18-19) (2000) 4449.

L. Gremillard, E. Saiz, J. Chevalier and A. P. Tomsia, Z. Metallkd. 95(4) (2004) 261.

Ihsan Barin, “Thermochemical Data of Pure Substances” (VCH, 1989).

N. Sobczak, L. Stobierski, W. Radziwill, M. Ksiazek and M. Warmuzek, Surf. Interface Anal. 36 (2004) 1067.

E. A. Brandes and G. B. Brook, “Smithells Light Metals Handbook” (Butterworth-Hinemann, 1998) p. 5.

M. Miryayama, K. Koumoto and H. Yanagida, “Engineered Materials Handbook” (1991) Vol. 4, p. 748.

A. B. D. Cassie, Discuss. Faraday Soc. 3 (1948) 11.

S. Otsuka and Z. Kozuka, Trans. Jap. Inst. Met. 22(8) (1981) 558.

C. W. Hsu and C. G. Chao, Metall. Mater. Trans. B. 33B (2002) 31.

R. G. Reddy, X. Wen and I. C. I. Okafor, Metall. Mater. Trans. A. 32A(3) (2001) 491.

X. B. Zhou and J. Th. M. De Hosson, J. Mater. Sci. 30(14) (1995) 3571.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Avraham, S., Kaplan, W.D. Reactive wetting of rutile by liquid aluminium. J Mater Sci 40, 1093–1100 (2005). https://doi.org/10.1007/s10853-005-6922-4

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s10853-005-6922-4