Abstract

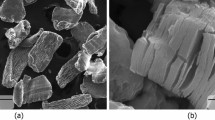

In the present study, magnesium based composites containing galvanised iron wire mesh and carbon fibres as continuous reinforcement were fabricated using the disintegrated melt deposition technique followed by hot extrusion. Microstructural characterisation of the extruded composite samples showed minimal porosity and good interfacial integrity between iron wire mesh and the matrix. The penetration of magnesium in between carbon fibres remains limited. Mechanical characterization revealed that the addition of reinforcements lead to an increase in hardness, dynamic modulus and 0.2%YS, did not affect the UTS and reduced the ductility. The overall mechanical performance of the composite with hybrid reinforcement synthesized in this study remained superior when compared to conventional composite formulations with comparatively higher volume fraction of reinforcement.

Similar content being viewed by others

References

H. P. DEGISCHER, M. DOKTOR and P. PRADER, in “Metal Matrix Composites and Metallic Foams”, edited by T. W. Clyne et al., “Euromat 99” (Wiley-VCH, Weinheim, 2000) Vol. 5, p. 113.

B. TERRY and G. JONES, in “Metal Matrix Composites: Current Developments and Future Trends in Industrial Research and Applications” (Elsevier Advanced Technology, Oxford, 1990) p. 41.

V. LAURENT, P. JARRY, G. REGAZZONI and D. APELIAN, J. Mater. Sci. 27 (1992) 4447.

D. J. LLYOD, Int. Mater. Rev. 39 (1994) 1.

A. LUO, Metal. Mater. A 26 (1995) 2445.

D. M. LEE, B. K. SUH, B. G. KIM, J. S. LEE and C. H. LEE, Mater. Sci. Technol. 13 (1997) 590.

T. EBERT, F. MOLL and K. U. KAINER, Powder Metal. 40 (1997) 126.

D. J. TOWLE and C. M. FRIEND, Mater. Sci. Eng. A 188 (1994) 153.

R. UNVERRICHT, V. PEITZ, W. RIEHEMANN and H. FERKEL, in “Magnesium Alloys and their Applications” (Werkstoff-Informationsgesellschaft mbH, Germany, 1998) p. 327.

I. W. HALL, J. Mater. Sci. 26 (1991) 776.

M. RUSSELL-STEVENS, D. C. PLANE, J. SUMMERSCALES, P. SCHULZ and M. PAPAKYRIACOU, Mater. Sci. Technol. 18 (2002) 501.

V. V. GANESH and M. GUPTA, Mater. Res. Bull. 35 (2000) 2275.

S. F. HASSAN and M. GUPTA, Mater. Res. Bull. 37 (2002) 337.

S. F. HASSAN and M. GUPTA, J. Alloy Compd. 335 (2002) 10.

S. F. HASSAN and M. GUPTA, J. Alloy Compd. 345 (2002) 246.

R. CHEN and X. LI, Compos. Sci. Technol. 49 (1993) 357.

R. WU, in “Composite Interfaces (ICCI-II)” (Elsevier Science Publishing, Cleveland, Ohio, 1988) p. 43.

S. P. RAWAL and M. S. MISRA, in “Composite Interfaces (ICCI-II)” (Elsevier Science Publishing, Cleveland, Ohio, 1988) p. 179.

P. SCHULZ, H. KAUFMANN and H. CAPEL, in “Metal Matrix Composites and Metallic Foams”, edited by T. W. Clyne et al., Euromat 99 (Wiley-VCH, Weinheim, 2000) Vol. 5 p. 128.

M. OTTMULLER, C. KORNER and R. F. SINGER, in “Metal Matrix Composites and Metallic Foams”, edited by T. W. Clyne et al., Euromat 99 (Wiley-VCH, Weinheim, 2000) Vol. 5, p. 168.

J. SCHRODER and K. U. KAINER, Mater. Sci. Eng. A 135 (1991) 33.

F. WU, J. ZHU, Y. CHEN and G. ZHANG, Mater. Sci. Eng. A 277 (2000) 143.

T. W. CHOU, in “Microstructural Design of Fiber Composites” (Cambridge University Press, Cambridge, New York, 1993) p. 231.

Hexcel Fibers website, IM7 HS-CP5000 Carbon Fiber Product Data, http://www.hexcelfibers.com/Tools/Downloads/default.htm (accessed Sept. 2004).

M. GUPTA, M. O. LAI and C. Y. SOO, Mater. Res. Bull. 30 (1995) 1525.

M. GUPTA, L. M. THAM and L. CHENG, Mater. Sci. Technol. 15 (1999) 1139.

M. GUPTA, M. O. LAI and D. SARAVANARANGANTHAN, J. Mater. Sci. 35 (2000) 2155.

M. GUPTA, C. LANE and E. J. LAVERNIA, Scr. Metall. Mater. 26 (1992) 825.

B. D. CULLITY, in “Elements of X-ray Diffraction”, 2nd edn (Addison-Wesley, Reading, MA, 1978) p. 414.

R. K. EVERETT and R. J. ARSENAULT, in “Metal Matrix Composites” (Academic Press Publishers, Boston, 1991) p. 64.

R. ASTHANA, J. Mater. Synth. Proces. 5 (1997) 251.

M. GUPTA, L. SU and T. S. SRIVATSAN, Revi. Proc. Chem. Engng. 1 (1998) 179.

M. GUPTA, M. O. LAI and M. S. BOON, Mater. Res. Bull. 33 (1998) 1387.

B. L. MORDIKE and P. LUKAC, Surf Interf. Anal. 31 (2001) 682.

S. P. RAWAL, Surf Interf. Anal. 31 (2001) 692.

A. MORTENSEN, Mater. Sci. Eng. A 135 (1991) 1.

J. JACKOWSKI, in “Metal Matrix Composites and Metallic Foams”, edited by T. W. Clyne et al., Euromat 99 (Wiley-VCH, Weinheim, 2000) Vol. 5, p. 133.

V. V. GANESH, P. K. TAN and M. GUPTA, J. Alloy Compd. 315 (2001) 203.

L. TAO and F. DELANNAY, Acta Mater. 46 (1998) 6497.

M. R. KRISHNADEV, R. ANGERS, C. G. KRISHNADAS NAIR and G. J. HUARD, J. Mater. 45 (1993) 52.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wong, W.L.E., Gupta, M. Using hybrid reinforcement methodology to enhance overall mechanical performance of pure magnesium. J Mater Sci 40, 2875–2882 (2005). https://doi.org/10.1007/s10853-005-2429-2

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s10853-005-2429-2