Abstract

The wetting of zirconia by a number of pure metals was studied.

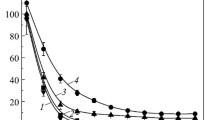

The wetting of zirconia by Cu-Ga-Ti, Cu-Ga-Zr, Cu-Ge-Ti and Cu-Ge-Zr alloys was studied. For Cu-Ga-Ti the minimal contact angle was near 60∘, for Cu-Ga-Zr it was near 30∘. Cu-Ge based alloys wet the zirconia worse because of the low solubility of titanium and zirconium in germanium.

The wetting of different zirconia ceramic by a few molten alloys was compared. Contact angles for equal alloys are close. The substrate structure influences the wetting: polycrystal zirconia is wetted by active alloys worse than monocrystal form.

The kinetic of ZrO2 variation of stoichiometry in contact with active alloys was investigated. The dark zone dimension was found to very according a to parabolic law; and the diffusion coefficients of F-centers in ZrO2-ceramic were calculated.

For Cu-Ga-Ti on zirconia adsorption of titanium on the substrate surface and the formation of a TiO layer close to zirconia was revealed. Similarly, for Cu-Ga-Zr adsorption of zirconium on substrate was also found. Interface reactions were described, showing negative Gibbs energy. The average F-centers concentration was calculated.

Metals wet better nonstoichiometric than stoichiometric zirconia. At contact to noble metals melts in a vacuum nonstoichiometric (black) zirconia becomes white. Obviously Zr–O bond are weak in black zirconia and a larger quantity of zirconium/metal bonds forms, so the black zirconia is wetted better.

When in contact to noble metals some part of zirconium diffuse into metal and so the oxygen deficit disappears.

Finally, The brazing of zirconia to metal was briefly discussed.

Similar content being viewed by others

References

Y. V. NAIDICH, B. D. KOSTJUK, V. V. KHRISTOV and A. V. SHEVCHENKO, Adgjezi. Rasplav. Pajka Matjerialov 27(53) (1992) (in Russian).

V. M. PEREVERTAJLO, O. B. LOGINIVA, A. V. IACMIRSKIJI, N. G. BAGNO and V. I. KORBANJ, Svjerhtvjordije materiali 3(15) (1998) (in Russian).$

M. UEKI, M. NAKA and I. OKAMOTO, J. Mater. Sci. Lett. 5 (1986) 1261.

M. HUMENIK and W. KINGERY, J. Amer. Cer. Soc. 37 (1954) 18.

J. G. DUH, W. S. CHIEN and B. S. CHIOU, J. Mat. Sci. Lett. 8(4) (1989) 405.

C. D. QIN, C. C. YU, H. L. NGO, L. C. LIM and M. C. LAI, Mater. Lett. 26(12) (1996) 17.

N. I. FRUMINA, Wetting and Contact Interaction of Metal Melts and Oxides of Rear Metal Melts, Aluminia and Monocrystall Materials on These Base. Abstract of Thesis on Competition of Academic Degree of Candidate of Science (Kiev, Ukraine, 1985) p. 21 (in Russian).

T. JALOVETS and V. A. BORODIN, in Proceedings of the Academy of Sciences of USSR. Inorganic materials., 1988, Vol. 26, No. 16, p. 946. (in Russian).

Rights and permissions

About this article

Cite this article

Durov, A.V., Naidich, Y.V. & Kostyuk, B.D. Investigation of interaction of metal melts and zirconia. J Mater Sci 40, 2173–2178 (2005). https://doi.org/10.1007/s10853-005-1928-5

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s10853-005-1928-5