Abstract

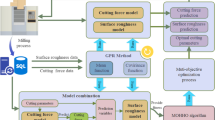

The industry faces a trend of fabricating a product with high-variety and short life cycles since the change of consumer behaviors. The quality control becomes critical. In milling process, surface roughness is key quality characteristic measured by an off-line method. The off-line measurement is time consuming. Therefore, online surface roughness monitoring systems, which can eliminate the measurement time and enhance the productivity, have gained popularity for machining. However, to accurately construct the system, a large amount of data and time for off-line training and modeling are required, which make the system not suitable for a high-variety job shop production. It is necessary to develop a method without large data and off-line training and modeling. Therefore, a Grey online modeling surface roughness monitoring (GOMSRM) system is proposed in this study by utilizing the Grey theory GM(1, N) with bilateral best-fit method, which requires less data and no training time to perform the online modeling surface roughness monitoring system. The ability of an online modeling makes the system flexible to monitor different types of products. The model could be built during each changeover process of the milling, which can significantly eliminate the time of training in advance used by other off-line modeling methods. The results show the GOMSRM system can accurately predict the surface roughness. The comparison between the GOMSRM system and the system developed by a neural network shows the GOMSRM system has better accuracy and fewer samples for modeling.

Graphical Abstract

Similar content being viewed by others

References

Aguilar, A., Roman-Flores, A., & Huegel, J. C. (2013). Design, refinement, implementation and prototype testing of a reconfigurable lathe-mill. Journal of Manufacturing Systems, 32(2), 364–371.

Ak, R., Li, Y., Vitelli, V., Zio, E., Droguett, E. L., & Jacinto, C. M. C. (2013). NSGA-II-trained neural network approach to the estimation of prediction intervals of scale deposition rate in oil & gas equipment. Expert Systems with Applications, 40(4), 1205–1212.

Alavi, A. H., & Gandomi, A. H. (2011). Prediction of principal ground-motion parameters using a hybrid method coupling artificial neural networks and simulated annealing. Computers & Structures, 89(23), 2176–2194.

Altintas, Y., & Yellowley, I. (1989). In-process detection of tool failure in milling using cutting force models. Journal of Engineering for Industry, 111(2), 149–157.

Alvisi, S., & Franchini, M. (2012). Grey neural networks for river stage forecasting with uncertainty. Physics and Chemistry of the Earth, Parts A/B/C, 42, 108–118.

Benítez, R. B. C., Paredes, R. B. C., Lodewijks, G., & Nabais, J. L. (2013). Damp trend Grey Model forecasting method for airline industry. Expert Systems with Applications, 40(12), 4915–4921.

Black, J. T., & Kohser, R. A. (2011). DeGarmo’s materials and processes in manufacturing (11th ed.). New York: Wiley.

Bouacha, K., Yallese, M. A., Mabrouki, T., & Rigal, J. F. (2010). Statistical analysis of surface roughness and cutting forces using response surface methodology in hard turning of AISI 52100 bearing steel with CBN tool. International Journal of Refractory Metals and Hard Materials, 28(3), 349–361.

Cakir, M. C., & Isik, Y. (2005). Detecting tool breakage in turning aisi 1050 steel using coated and uncoated cutting tools. Journal of Materials Processing Technology, 159(2), 191–198.

Çaydaş, U., & Ekici, S. (2012). Support vector machines models for surface roughness prediction in CNC turning of AISI 304 austenitic stainless steel. Journal of Intelligent Manufacturing, 23(3), 639–650.

Chen, J. C., & Huang, B. (2003). An in-process neural network-based surface roughness prediction (INN-SRP) system using a dynamometer in end milling operations. International journal of Advanced Manufacturing Technology, 21(5), 339–347.

Chen, J. C., & Lou, M. S. (2000). Fuzzy-nets based approach to using an accelerometer for an in-process surface roughness prediction system in milling operations. International Journal of Computer Integrated Manufacturing, 13(4), 358–368.

Deng, J.-L. (1982). Control problems of grey systems. Systems & Control Letters, 1(5), 288–294.

Fetecau, C., & Stan, F. (2012). Study of cutting force and surface roughness in the turning of polytetrafluoroethylene composites with a polycrystalline diamond tool. Measurement, 45(6), 1367–1379.

Franco, P., Estrems, M., & Faura, F. (2004). Influence of radial and axial runouts on surface roughness in face milling with round insert cutting tools. International Journal of Machine Tools and Manufacture, 44(15), 1555–1565.

Guo, J. J., Wu, J. Y., & Wang, R. Z. (2011). A new approach to energy consumption prediction of domestic heat pump water heater based on grey system theory. Energy and Buildings, 43(6), 1273–1279.

Huang, B. P., Chen, J. C., & Li, Y. (2008). Artificial-neural-networks-based surface roughness Pokayoke system for end-milling operations. Neurocomputing, 71(4), 544–549.

Huang, P. B. (2016). An intelligent neural-fuzzy model for an in-process surface roughness monitoring system in end milling operations. Journal of Intelligent Manufacturing, 27(3), 689–700.

Huang, P. B., Ma, C. C., & Kuo, C. H. (2015a). A PNN self-learning tool breakage detection system in end milling operations. Applied Soft Computing, 37, 114–124.

Huang, P. B., Zhang, H. J., & Chen, J. C. (2015b). Implementing grey relation for surface rougness analysis in milling operations. In IEEE 2015 international conference on machine learning and cybernetics (ICMLC), Vol. 1, pp. 414–419.

Koo, J. Y., Kim, J. S., & Kim, P. H. (2014). Machining characteristics of micro-flow channels in micro-milling process. Machining Science and Technology, 18(4), 509–521.

Kuram, E., & Ozcelik, B. (2014). Micro-milling performance of AISI 304 stainless steel using Taguchi method and fuzzy logic modelling. Journal of Intelligent Manufacturing, 27, 817–830. doi:10.1007/s10845-014-0916-5.

Li, D. C., Chen, L. S., & Lin, Y. S. (2003). Using functional virtual population as assistance to learn scheduling knowledge in dynamic manufacturing environments. International Journal of Production Research, 41(17), 4011–4024.

Lin, H. L. (2012). The use of the Taguchi method with grey relational analysis and a neural network to optimize a novel GMA welding process. Journal of Intelligent Manufacturing, 23(5), 1671–1680.

Lin, S. C., & Lin, R. J. (1996). Tool wear monitoring in face milling using force signals. Wear, 198(1), 136–142.

Mehregan, M. R., Jamporazmey, M., Hosseinzadeh, M., & Kazemi, A. (2012). An integrated approach of critical success factors (CSFs) and grey relational analysis for ranking KM systems. Procedia-Social and Behavioral Sciences, 41, 402–409.

Pai, T. Y., Chiou, R. J., & Wen, H. H. (2008). Evaluating impact level of different factors in environmental impact assessment for incinerator plants using GM (1, N) model. Waste Management, 28(10), 1915–1922.

Quintana, G., Garcia-Romeu, M. L., & Ciurana, J. (2011). Surface roughness monitoring application based on artificial neural networks for ball-end milling operations. Journal of Intelligent Manufacturing, 22(4), 607–617.

Ramamurthi, K., & Hough, C. L. (1993). Intelligent real-time predictive diagnostics for cutting tools and supervisory control of machining operations. Journal of Engineering for industry, 115(3), 268–277.

Samvedi, A., & Jain, V. (2013). A grey approach for forecasting in a supply chain during intermittentdisruptions. Engineering Applications of Artificial Intelligence, 26(3), 1044–1051.

Shahrom, M. S., Yahya, N. M., & Yusoff, A. R. (2013). Taguchi method approach on effect of lubrication condition on surface roughness in milling operation. Procedia Engineering, 53, 594–599.

Tangjitsitcharoen, S., Thesniyom, P., & Ratanakuakangwan, S. (2017). Prediction of surface roughness in ball-end milling process by utilizing dynamic cutting force ratio. Journal of Intelligent Manufacturing, 28(1), 13–21.

Tarng, Y. S., & Lee, B. Y. (1993). A sensor for the detection of tool breakage in NC milling. Journal of Materials Processing Technology, 36(3), 259–272.

Tian, S. F., Jiang, L. T., Guo, Q., & Wu, G. H. (2014). Effect of surface roughness on tribological properties of TiB 2/Al composites. Materials & Design, 53, 129–136.

Turner, R., Panciera, R., Tanase, M. A., Lowell, K., Hacker, J. M., & Walker, J. P. (2014). Estimation of soil surface roughness of agricultural soils using airborne LiDAR. Remote Sensing of Environment, 140, 107–117.

Wang, C. H., & Hsu, L. C. (2008). Using genetic algorithms Grey theory to forecast high technology industrial output. Applied Mathematics and Computation, 195(1), 256–263.

Wang, K. C. (2011). A hybrid Kansei engineering design expert system based on grey system theory and support vector regression. Expert Systems with Applications, 38(7), 8738–8750.

Xia, T., Jin, X., Xi, L., Zhang, Y., & Ni, J. (2015). Operating load based real-time rolling grey forecasting for machine health prognosis in dynamic maintenance schedule. Journal of Intelligent Manufacturing, 26(2), 269–280.

Xiao, X. C., Wang, X. Q., Fu, K. Y., & Zhao, Y. J. (2012). Grey relational analysis on factors of the quality of web service. Physics Procedia, 33, 1992–1998.

Yun, H. T., Heo, S., Lee, M. K., Min, B. K., & Lee, S. J. (2011). Ploughing detection in micromilling processes using the cutting force signal. International Journal of Machine Tools and Manufacture, 51(5), 377–382.

Zeng, G., Jiang, R., Huang, G., Xu, M., & Li, J. (2007). Optimization of wastewater treatment alternative selection by hierarchy grey relational analysis. Journal of Environmental Management, 82(2), 250–259.

Acknowledgements

This research was supported by the Ministry of Science and Technology, Taiwan, ROC (Contract Nos. 103-2221-E-033-059).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, P.B., Zhang, HJ. & Lin, YC. Development of a Grey online modeling surface roughness monitoring system in end milling operations. J Intell Manuf 30, 1923–1936 (2019). https://doi.org/10.1007/s10845-017-1361-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-017-1361-z