Abstract

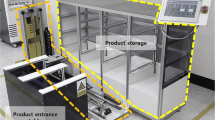

Achieving high quality production of light-emitting diode (LED) wafers requires robust monitoring and the use of a stable test machine. In many factories, production continues 24 h a day. Stopping the manufacturing process at a factory is often difficult. Therefore, reducing inspection time and ensuring the stability of test machines are important. Traditionally, LED wafer factories examine their test machines during periodic maintenance. Standard lamp adjustments are performed to ensure their accuracy. This process interrupts the manufacturing process and requires extra manpower. It reduces productivity and increases production cost. Additionally, the accurate assessment of the aging of the components of the machine requires an experienced engineer. Correctly timing the maintenance and replacing the aging components of the LED wafer test machine are important. This work performed feature extraction to identify the working attributes of an LED wafer test machine. The intelligent maintenance prediction system then uses the radial basis function neural network and variability of the working attributes to predict the maintenance times and aging of the LED wafer test machines. Experimental results reveal that the accuracy of proposed system in predicting maintenance times exceeds 98 %.

Similar content being viewed by others

References

Aouf, M., Lyanage, L., & Hansen, S. (2008). Review of data mining clustering techniques to analyze data with high dimensionality as applied in gene expression data. In Proceedings of the international conference on service systems and service management (pp. 1–5).

Balabanov, T., Hristova, P. K., Doukovska, L., Hadjiski, M., & Beloreshki, S. (2011). Neural network model of mill-fan system elements vibration for predictive maintenance. In Proceedings of the international symposium on innovations in intelligent systems and applications (pp. 410–414).

Bastos, P., Lopes, R., Pires, L., & Pedrosa, T. (2009). Maintenance behavior-based prediction system using data mining. In Proceedings of the IEEE international conference on industrial engineering and engineering management (pp. 2487–2491).

Bennane, A., & Yacout, S. (2012). LAD-CBM; new data processing tool for diagnosis and prognosis in condition-based maintenance. Journal of Intelligent Manufacturing, 23(2), 265–275.

Chang, C. Y., Chang, C. H., Li, C. H., & Jeng, M. D. (2008). Learning vector quantization neural networks for LED wafer defect inspection. International Journal on Innovative Computing, Information and Control, 4(10), 2565–2579.

Chang, C. Y., Li, C. H., Lin, S. Y., & Jeng, M. D. (2009). Application of two hopfield neural networks for automatic four-element LED inspection. IEEE Transactions on Systems, Man, and Cybernetics, Part C: Applications and Reviews, 39(3), 352–365.

Chang, C. Y., Li, C. H., Chang, Y. C., & Jeng, M. D. (2011). Wafer defect inspection by neural analysis of region features. Journal of Intelligent Manufacturing, 22(6), 953–964.

Chen, W. C., & Hsu, S. W. (2007). A neural-network approach for an automatic LED inspection system. Expert Systems with Applications, 33(2), 531–537.

Chen, Z., Zhang, Q., Jiao, F., Chen, R., Wang, K., Chen, M., et al. (2012). Study on the reliability of application-specific LED package by thermal shock testing, failure analysis, and fluid-solid coupling thermo-mechanical simulation. IEEE Transactions on Components, Packaging and Manufacturing Technology, 2(7), 1135–1142.

Cheng, C. S., & Cheng, H. P. (2008). Identifying the source of variance shifts in the multivariate process using neural networks and support vector machines. Expert System with Applications, 35(1), 198–206.

Cheng, F. T., Huang, H. C., & Kao, C. A. (2012). Developing an automatic virtual metrology system. IEEE Transactions on Automation Science and Engineering, 9(1), 181–188.

Ding, F., He, Z., Zi, Y., Chen, X., Tan, J., Cao, H., & Chen, H. (2008). Application of support vector machine for equipment reliability forecasting. In Proceedings of the IEEE international conference on industrial informatics (pp. 526–530).

Ebrahimipour, V., Najjarbashi, A., & Sheikhalishahi, M. (2013). Multi-objective modeling for preventive maintenance scheduling in a multiple production line. Journal of Intelligent Manufacturing. doi:10.1007/s10845-013-0766-6.

Foguem, B. K., & Noyes, D. (2013). Graph-based reasoning in collaborative knowledge management for industrial maintenance. Computers in Industry, 64(8), 998–1013.

Gaertner, A. A. (2002). LED measurement issues. NIST Measurement Course on Photometry, Radiometry and Colorimetry, Lecture 15. Available at: http://www.goochandhousego.com/products/ol-770led-test-and-measurement-system/R24_LED-MEASUREMENT-ISSUES_NRC_1-03_GH.pdf

Gokulachandran, J., & Mohandas, K. (2013). Comparative study of two soft computing techniques for the prediction of remaining useful life of cutting tools. Journal of Intelligent Manufacturing. doi:10.1007/s10845-013-0778-2.

Gu, Y., & Narendran, N. (2004). A non-contact method for determining junction temperature of phosphor-converted white LEDs. In Proceedings of the 3rd conference on solid state lighting (pp. 107–114).

Hu, C., Youn, B. D., Wang, P., & Yoon, J. T. (2012). Ensemble of data-driven prognostic algorithms for robust prediction of remaining useful life. Reliability Engineering & System Safety, 103(7), 120–135.

Hung, M. H., Tsai, W. H., Yang, H. C., Kao, Y. J., & Cheng, F. T. (2012). A novel automatic virtual metrology system architecture for TFT-LCD industry based on main memory database. Robotics and Computer-Integrated Manufacturing, 28(4), 559–568.

Huang, L., Chen, Y., Chen, S., & Jiang, H. (2012). Application of RCM analysis based predictive maintenance in nuclear power plants. In Proceedings of the international conference on quality, reliability, risk, maintenance, and safety engineering (pp. 1015–1021).

International Commission on Illumination. (2006). Measurement of LEDs, International Commission on Illumination 127 Rev. 2 Draft.

Javed, K., Gouriveau, R., Zemouri, R., Zerhouni, N. (2012). Features selection procedure for prognostics: an approach based on predictability. In Proceedings of the 8th IFAC international symposium on fault detection, supervision and safety for technical processes (pp. 25–30).

Jiang, W. (2008). Research on predictive maintenance for hydropower plant based on MAS and NN. Pervasive Computing and Applications, 2(2), 604–609.

Joshi, P., Imadabathuni, M., He, D., Al-Kateb, M., & Bechhoefer, E. (2012). Application of the condition based maintenance checking system for aircrafts. Journal of Intelligent Manufacturing, 23(2), 277–288.

Koh, L. H., Tan, Y. K., Wang, Z. Z., & Tseng, K. J. (2012). An energy-efficient low voltage DC grid powered smart LED lighting system. In Proceedings of the annual conference on IEEE industrial electronics society (pp. 2883–2888).

Kumar, P., & Srivastava, R. K. (2012). An expert system for predictive maintenance of mining excavators and its various forms in open cast mining. In Proceedings of the international conference on recent advances in information technology (pp. 658–661).

Li, L. L., Wen, J., Li, P., Wen, Y., & Yin, F. (2008). Online non-contact fault detection of LED chips. In Proceedings of the 7th world congress on intelligent control and automation (pp. 280–283).

Liao, W., Pan, E., & Xi, L. (2010). Preventive maintenance scheduling for repairable system with deterioration. Journal of Intelligent Manufacturing, 21(6), 875–884.

Lin, H. D. (2009). Automated defect inspection of light-emitting diode chips using neural network and statistical approaches. Expert Systems with Applications, 36(1), 219–226.

Liu, J., Wang, W., Ma, F., Yang, Y. B., & Yang, C. S. (2012). A data-model-fusion prognostic framework for dynamic system state forecasting. Engineering Applications of Artificial Intelligence, 25(4), 814–823.

Moyne, J., Ward, N., & Hawkins, P. (2012). Leveraging advanced process control (APC) technology in developing predictive maintenance (PdM) systems. In Proceedings of the 23rd advanced semiconductor manufacturing conference (pp. 221–226).

Naderi, B., Zandieh, M., & Fatemi Ghomi, S. M. T. (2009). A study on integrating sequence dependent setup time flexible flow lines and preventive maintenance scheduling. Journal of Intelligent Manufacturing, 20(6), 683–694.

Orth, P., Yacout, S., & Adjengue, L. (2012). Accuracy and robustness of decision making techniques in condition based maintenance. Journal of Intelligent Manufacturing, 23(2), 255–264.

Rickli, J., Camelio, J., Dreyer, J., & Pandit, S. (2011). Fault detection and prognosis of assembly locating systems using piezoelectric transducers. Journal of Intelligent Manufacturing, 22(6), 909– 918.

Ruiz, P. A. P., Foguem, B. K., & Noyes, D. (2013). Knowledge reuse integrating the collaboration from experts in industrial maintenance management. Knowledge-Based Systems, 50, 171–186.

Sheu, D. D., & Kuo, J. Y. (2006). A model for preventive maintenance operations and forecasting. Journal of Intelligent Manufacturing, 17(4), 441–451.

Su, C. T., Yang, T., & Ke, C. M. (2002). A neural-network approach for semiconductor wafer post-sawing inspection. IEEE Transactions on Semiconductor Manufacturing, 15(2), 260–266.

Tian, Z. (2012). An artificial neural network method for remaining useful life prediction of equipment subject to condition monitoring. Journal of Intelligent Manufacturing, 23(2), 227–237.

Tsai, D. M., Chiang, I. Y., & Tsai, Y. H. (2012). A shift-tolerant dissimilarity measure for surface defect detection. IEEE Transactions on Industrial Informatics, 8(1), 128–137.

Vipradas, A., Takawale, A., Tripathi, S., & Swakul, V. (2012). A parametric study of a typical high power LED package to enhance overall thermal performance. In Proceedings of the IEEE intersociety conference on thermal and thermomechanical phenomena in electronic systems (pp. 308–313).

Wu, S. J., Gebraeel, N., & Lawley, M. A. (2007). A neural network integrated decision support system for condition-based optimal predictive maintenance policy. IEEE Transactions on Systems, Man and Cybernetics, Part A: Systems and Humans, 37(2), 226–236.

Wu, C.-H., Wang, D.-Z., Ip, A., Wang, D.-W., Chan, C.-Y., & Wang, H. F. (2008). A particle swarm optimization approach for components placement inspection on printed circuit boards. Journal of Intelligent Manufacturing, 20(5), 535–549.

Wu, W. M., Lin, T. H., Zeng, D. L., Chen, J. F., & Cheng, F. T. (2011). Selection schemes of dual virtual-metrology outputs for enhancing prediction accuracy. IEEE Transactions on Automation Science and Engineering, 8(2), 311–318.

Wu, W. M., Cheng, F. T., & Kong, F. W. (2012). Dynamic-moving-window scheme for virtual-metrology model refreshing. IEEE Transactions on Semiconductor Manufacturing, 25(2), 238–246.

Yang, Z., Djurdjanovic, D., & Ni, J. (2008). Maintenance scheduling in manufacturing systems based on predicted machine degradation. Journal of Intelligent Manufacturing, 19(1), 87–98.

Zhao, Z., Wang, F. I., Jia, M. X., & Wang, S. (2010). Predictive maintenance policy based on process data. Chemometrics and Intelligent Laboratory Systems, 103(2), 137–143.

Zheludev, N. (2007). The life and times of the LED—a 100-year history. Nature Photonics, 1(4), 189–192.

Zong, Y., & Ohno, Y. (2008). New practical method for measurement of high-power LEDs. In Proceedings of the CIE expert symposium 2008 on advances in photometry and colorimetry (pp. 102–106).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hsu, CC., Chen, MS. Intelligent maintenance prediction system for LED wafer testing machine. J Intell Manuf 27, 335–342 (2016). https://doi.org/10.1007/s10845-013-0866-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-013-0866-3