Abstract

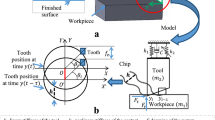

Cutting force signals exhibit a set of stochastic elements that repeat also in a stochastic manner. In this study, it is shown that nonstationary Gaussian processes (i.e., processes wherein the mean and the standard deviation of a normally distributed variable change with time) are able to model and simulate the stochastic elements of cutting force signals. The effectiveness of the proposed approach is demonstrated by comparing the simulated cutting force signal with real cutting force signal in terms of both frequency spectrum and correlation dimension. As realistic and user-friendly simulation of cutting force signals is needed for better process planning and monitoring of material removal processes, the use of the presented approach will help in this regard.

Similar content being viewed by others

References

Altintas Y., Brecher C., Weck M., Witt S.: Virtual machine tool. Annals of the CIRP 54(2), 115–138 (2005). doi:10.1016/S0007-8506(07)60022-5

Bhattacharyya P., Sengupta D., Mukhopadhyay S.: Cutting force-based real-time estimation of tool wear in face milling using a combination of signal processing techniques. Mechanical Systems and Signal Processing 21(6), 2665–2683 (2007). doi:10.1016/j.ymssp.2007.01.004

Brinksmeier E., Aurich J.C., Govekar E., Heinzel C., Hoffmeister H.-W., Klocke F., Peters J., Rentsch R., Stephenson D.J., Uhlmann E., Weinert K., Wittmann M.: Advances in modeling and simulation of grinding processes. Annals of the CIRP 55(2), 667–696 (2006). doi:10.1016/j.cirp.2006.10.003

Brown C.A.: Issues in modeling machined surface textures. Machining Science and Technology 4(3), 539–546 (2000). doi:10.1080/10940340008945721

Gradisek J., Grabec I., Siegert S., Friedrich R.: Stochastic dynamics of metal cutting: Bifurcation phenomena in turning. Mechanical Systems and Signal Processing 16(5), 831–840 (2002). doi:10.1006/mssp.2001.1403

Grabec I.: Chaotic dynamics of the cutting process. International Journal of Machine Tools & Manufacture 28(1), 19–32 (1988). doi:10.1016/0890-6955(88)90004-1

Grassberger P., Procaccia I.: Characterization of Strange Attractors. Physical Review Letters 50(5), 346–349 (1983). doi:10.1103/PhysRevLett.50.346

Higuchi M., Yano A., Yamamoto N., Yamaguchi T., Ikawa N., Kijima S., Kenmoku N.: Chaotic characteristics of mirror-finished surface produced by ultra-precision turning. Journal of the Japan Society of Precision Engineering 64(8), 1196–1200 (1998) (in Japanese)

Hillier F.S., Lieberman G. J.: Introduction to operations research, 8th edn. McGraw Hill, New York (2005)

Hively L.M., Protopopescu V.A., Clapp N.E., Daw C.S. (1998). Prospects for chaos control of machine tool chatter, Oak Ridge National Laboratory Report ORNL/TM-13283. Oak Ridge, TN, USA.

Ikua B.W., Tanaka H., Obata F., Sakamoto S.: Prediction of cutting forces and machining error in ball end milling of curved surfaces -I theoretical analysis. Precision Engineering 25(4), 266–273 (2001). doi:10.1016/S0141-6359(01)00077-0

Kantz H., Schreiber T.: Nonlinear time series analysis. Cambridge University Press, Cambridge (1997)

Liang S.Y., Hecker R.L., Landers R.G.: Machining process monitoring and control: The state-of-the-art, ASME transactions. Journal of Manufacturing Science and Engineering 126(2), 297–310 (2004). doi:10.1115/1.1707035

Mastuda T., Tanaka F., Onosato M., Date H.: Development of a digital machining information model to support a real-virtual machining systems. Journal of Advanced Mechanical Design, Systems and Manufacturing 2(4), 597–608 (2008). doi:10.1299/jamdsm.2.597

Moon F.C., Kalmar T.-N.: Nonlinear models for complex dynamics in cutting materials. Philosophical Transactions: Mathematical, Physical and Engineering Sciences 359(1781), 695–711 (2001). doi:10.1098/rsta.2000.0751

Radhakrishnan T., Nandan U.: Milling force prediction using regression and neural networks. Journal of Intelligent Manufacturing 16(1), 93–102 (2005). doi:10.1007/s10845-005-4826-4

Raman S., Longstreet A., Guha D.: A fractal view of tool-chip interfacial friction in machining. Wear 253(11–12), 1111–1120 (2002). doi:10.1016/S0043-1648(02)00238-7

Teti R., Jawahir I.S., Jemielniak K., Segreto T., Chen S., Kossakowska J.: Chip form monitoring through advanced processing of cutting force sensor signals. Annals of the CIRP 55(1), 75–80 (2006). doi:10.1016/S0007-8506(07)60370-9

Tsai C.-L., Liao Y.-S.: Prediction of cutting forces in ball-end milling by means of geometric analysis. Journal of Materials Processing Technology 205(1–3), 24–33 (2008). doi:10.1016/j.jmatprotec.2007.11.083

Ullah A.M.M.S. (2005). Comparative study of various machining information sources. In Proceedings of the 8th CIRP workshop on modeling of machining operations (pp. 677–681). Chemnitz, Germany, May 10–11.

Ullah A.M.M.S., Harib K.H.: Manufacturing process performance prediction by integrating crisp and granular information. Journal of Intelligent Manufacturing 16(3), 319–332 (2005). doi:10.1007/s10845-005-7026-3

Ullah A.M.M.S., Harib K.H.: A human-assisted knowledge extraction method for machining operations. Advanced Engineering Informatics 20(4), 335–350 (2006a). doi:10.1016/j.aei.2006.07.004

Ullah A.M.M.S., Harib K.H.: Knowledge extraction from time series and its application to surface roughness simulation. Information Knowledge Systems Management 5(2), 117–134 (2006b). doi:10.1142/S0219649206001372

Ullah A.M.M.S., Harib K.H.: Zadehian paradigms for knowledge extraction in intelligent manufacturing, manufacturing the future: Concepts—technologies—visions. In: Kordic, V., Lazinica, A., Merdan, M. (eds) Pro Literatur Verlag Robert Mayer-Scholz, Chapter 10, pp. 291–308. Mammendorf, Germany (2006c)

Ullah, A. M. M. S., Harib, K. H., & Aldajah, S. (2006). On the roughness profile modeling using Q-Sequence. In Proceedings of the 9th CIRP workshop on modeling of machining operations (pp. 431–437). Bled, Slovenia, May 11–12.

Ullah A.M.M.S., Rahman M.R., Kachitvichyanuluk V., Harib K.H.: Fractal dimension: A new machining decision-making parameter. In: Meech, J.A., Kawazoe, Y., Kumar, V., Maguire, J.F. (eds) Intelligence in a small materials world, pp. 470–486. Lancaster, DEStech Publications (2005)

Wakabayashi T., Suda S., Inasaki I., Terasaka K., Musha Y., Toda Y.: Tribological action and cutting performance of MQL media in machining of aluminum. Annals of the CIRP 56(1), 97–100 (2007). doi:10.1016/j.cirp.2007.05.025

Wang, L., Gao R.X. (eds): Condition monitoring and control for intelligent manufacturing. Springer, London (2006)

Wang Z.G., Rahman M., Wong Y.S., Li X.P.: A hybrid cutting force model for high-speed milling of titanium alloys. Annals of the CIRP 54(1), 71–74 (2005). doi:10.1016/S0007-8506(07)60052-3

Wiercigroch M., Cheng A.H.-D.: Chaotic and stochastic dynamics of orthogonal metal cutting. Chaos, Solitons, and Fractals 8(4), 715–726 (1997). doi:10.1016/S0960-0779(96)00111-7

Wiercigroch M., Krivtsov A.M.: Frictional chatter in orthogonal metal cutting. Philosophical Transactions: Mathematical, Physical and Engineering Sciences 359(1781), 713–738 (2001). doi:10.1098/rsta.2000.0752

Weisstein, E. W. (2008). Central limit theorem, mathworld—a wolfram web resource. Last viewed September 4, 2008, 08:23am GMT, from http://mathworld.wolfram.com/CentralLimitTheorem.html.

Yamaguchi T., Higuchi M., Shimada S., Kaneeda T.: Tool life monitoring during the diamond turning of electroless Ni-P. Precision Engineering 31(3), 196–201 (2007). doi:10.1016/j.precisioneng.2006.07.002

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ullah, A.M.M.S., Harib, K.H. Simulation of cutting force using nonstationary Gaussian process. J Intell Manuf 21, 681–691 (2010). https://doi.org/10.1007/s10845-009-0245-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-009-0245-2