Abstract

Carotenoids are among the most widely distributed pigments in nature with broad application options in pharmacology, cosmetics and food industries. For commercial-scale production using microalgae, however, it is crucial to find the best performing strains regarding growth and yields of the products of interest. As terrestrial microalgae present the ability to quickly adapt to changing or unfavorable environmental conditions through cell-specific defense mechanisms, they constitute highly promising candidates. The present study thus aimed to investigate the potential of five terrestrial microalgal strains to increasingly produce the carotenoids β-carotene, canthaxanthin and astaxanthin when being exposed to UV-A stress. Light stress experiments were performed using a novel irradiation system based on UV-LED technology. Microalgal cultures were treated with UV-A radiation to stimulate carotenogenesis and the time-dependent effects were investigated by high-performance liquid chromatography analysis. The potential of the microalgae to enhance de novo biosynthesis of the targeted metabolites under the influence of UV-A light could be confirmed by significantly increased yields of canthaxanthin in four out of five strains and by a significantly enhanced β-carotene concentration in at least one strain during 72 h of investigation. Overall, the results provided evidence that UV-A light stress can be effective in rapidly inducing carotenogenesis in terrestrial microalgae and thus harbors vast potential for further exploitation regarding large-scale carotenoid production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Microalgae (MA) are a diverse, polyphyletic group of photosynthetic microorganisms. As the term ´algae´ does not refer to a systematic classification, besides eukaryotic algae also prokaryotic cyanobacteria are included by some authors (Sánchez-Bayo et al. 2020). Because of their diversity in terms of metabolism and their ability to grow photoautotrophically, microalgae possess a great potential for the production of valuable compounds and have gained increasing biotechnological interest (Borowitzka 2013). Although processes and products for the use in food, feed or cosmetics are already available, there is a great and largely unexploited potential for compounds also in other fields like the pharmaceutical industry (Cardozo et al. 2007).

While much research has been conducted on aquatic microalgae found in marine environments and fresh water, MA from non-aquatic ecosystems living on rocks, trees, and soil (Hoffmann 1989) have not received as much attention (Lakatos and Strieth 2017). As they are frequently exposed to harsh conditions such as drought, high temperature differences or ultraviolet (UV) irradiation, there should be an interesting arsenal of metabolites, which enable them to survive in these adverse environments (Huang et al. 2018; Rastogi et al. 2020). In particular, UV irradiation plays an important role as an environmental factor for microalgae which are found in alpine regions. Therefore, UV as a stress factor should induce the production of metabolites that protects these terrestrial microalgae from the detrimental effects.

Terrestrial microalgae are known to occur in at least six groups including Chlorophyceae and Trebouxiophyceae, with the latter harboring most of the currently known terrestrial strains (Rindi et al. 2011). Various biochemical, physiological, and morphological protective strategies such as photo/dark repair mechanisms, UV screens, biosynthesis of UV-photoprotectants including mycosporine like amino acids and carotenoids, or the formation of colonies and biofilms enable them to naturally withstand unfavorable external influences (Karsten 2008; Hodkinson et al. 2011; Medwed et al. 2021). In this context, the cell cluster of Diplosphaera spp. may be surrounded by a gelatinous matrix ensuring a high desiccation tolerance (Orekhova et al. 2019). Members of the genus Coccomyxa occur as soil algae or free-living in terrestrial green biofilms and associated with mosses (Darienko et al. 2015). With more than 60 described species, they display a remarkable versatility in habitat and lifestyle being abundant in temperate regions but also in strongly polluted and extreme environments like Antarctic soils with severe seasonal changes of UV radiation (La Rocca et al. 2009; Koechler et al. 2016; Pfaff et al. 2016; Kalinowska and Pawlik-Skowrońska 2010; Fais et al. 2021). Furthemore, Coccomyxa spp. are well known for their ability to accumulate high levels of triglycerides relevant for biofuel production (Fais et al. 2021). As Chromochloris related species exhibit diverse metabolic capabilities being able to grow under phototrophic, heterotrophic, and mixotrophic conditions (Zhang et al. 2021), they are among the most biotechnologically interesting oleaginous astaxanthin-producing microalgae. In this context, the production of astaxanthin using microalgae has already successfully been introduced to the global market as they dominate natural production per unit dry weight and far exceed the health-promoting properties compared with synthetic carotenoids (Novoveská et al. 2019). Thus, microalgae represent ideal candidates for exploring their adaptive strategies upon UV stress for industrial applications.

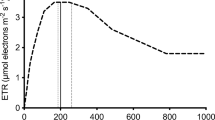

From an applied perspective, carotenoids are promising secondary metabolites with applications in medicine, food industry or cosmetics (Liu et al. 2021). These natural pigments exhibit both preventive or health-promoting properties, among which anti-inflammatory and antioxidant properties are the most relevant (Mc Gee et al. 2018). In algae carotenoids perform important functions during photosynthesis including light harvesting, photoprotection and they scavenge reactive oxygen species (ROS) (Sathasivam and Ki 2018; Novoveská et al. 2019). Up to now, most carotenoids are synthesized chemically though natural production using microalgae has long been recognized as a desirable and highly promising endeavour (Mussagy et al. 2019). According to the literature, carotenoids are widespread among living organisms, with more than 750 carotenoids being found in nature (Christaki et al. 2013; Pereira and Otero 2020). Currently, almost all cultivation techniques are processed under submerged conditions using aquatic microalgae, yet terrestrial microalgae exhibit several advantages over marine ones including desiccation tolerance and stable growth over a broad temperature range allowing efficient production performances under natural and artificial conditions (Lakatos and Strieth 2017). An accumulation of carotenoids in the aerial microalga Coelastrella striolata var. multistriata could be achieved by varying cultivation conditions according to the work of Abe et al. (2007). In the aerial alga Scenedesmus sp., isolated from rocks, enhanced carotenogenesis was found by increasing the photon flux density from 40 to 214 μmol photons m−2 s−1 (Aburai et al. 2013). In order to induce metabolites that can be protective under UV and oxidative conditions, bioreactors with appropriate irradiation systems can be employed, which provide not only the wavelengths for the photosynthetic growth in the visible range, but also defined parts of the UV spectrum for light stress (Liang et al. 2006; Nwoba et al. 2019). By using light-emitting diodes (LEDs), the irradiation conditions can be applied in a well-defined manner. Due to their intrinsic properties, LEDs provide a narrow spectral power distribution, and the emitted power can be precisely controlled (Bourget 2008). Their mechanical, electrical and optical characteristics enable the design of tailor-made lighting systems that can be implemented in existing experimental setups such as bioreactors. Therefore, the exact definition of the spectrum and reproducibility of the light conditions can be ensured using LED systems.

Considering the broad eco-physiological potential of terrestrial microalgae, we hypothesised that a targeted UV-A irradiation enhances carotenogenesis, more precisely of three relevant carotenoids, namely astaxanthin, canthaxanthin, and β-carotene. As the irradiation design further influences carotenogenesis, we also aimed to develop an optimized irradiation system based on LED technology to ensure standardized conditions. Therefore, five different strains of terrestrial MA were exposed to UV-A light stress under standardized irradiation conditions for up to 72 h, followed by 24 h regeneration without UV-A stress, and the impact on carotenoid production and microalgal growth (optical densities) was evaluated. As the investigated strains were not fully characterized, we additionally performed Sanger sequencing for taxonomic assignment.

Material and Methods

Microalgae cultivation and identification

Five microalgae strains (IB256, T3, V46, V142, and V224) that revealed sufficient growth characteristics (personal communication) were obtained from ASIB 505 (Gärtner 1996), a culture collection of more than 1500 soil-, airborne and lichen algae at the Botanical Institute of the University of Innsbruck (Austria). The strains were cultured on 3N-BBM (Bold Basal Medium according to Bischoff and Bold 1963) and modified by tripling the amount of nitrate to support active growth and promote biomass generation) agar slants for colony isolation and identification. To remove media components from the microalgae culture for further investigations, samples were washed three times by centrifugation (4000 rpm, 20 min, 20 °C, Rotanta 460 R Hettrich, Germany) and resuspended (Vortex Mixer 7-2020, neoLab Migge) in destilled water. The obtained biomass pellets were freeze-dried, pulverized and stored at room temperature until further use, like identification or metabolic analysis. Microscopic examinations were performed after seven days of cultivation using 20 μL of resuspended algal strains (in 100 μL 3N-BBM medium) using a Nikon Eclipse 50i microscope (Nikon, Japan). Extraction of genomic DNA was conducted using the Invisorb Spin Plant Mini Kit (Invitek Molecular, Germany) with the following modifications: 10 mg of dried biomass was covered with equal number of glass beads (diameter 0.25 to 0.5 mm) and suspended in 400 μL lysis buffer P and 20 μL proteinase K. After vortexing for 6 min (Vortex Mixer 7-2020, neoLab Migge), the samples were incubated at 65 °C for 60 min and 800 rpm, followed by centrifugation at 13.200 rpm for 2 min at 25 °C (miniSpin, Eppendorf, Germany). The resulting supernatant was then transferred onto the filters, the following steps were conducted according to the manufacturer´s instructions. The 18S small subunit ribosomal RNA gene was amplified by PCR using existing primers: NS1-SR5 (Pras A) and SR4-18L (Pras B) (Rindi et al. 2007; McManus and Lewis 2011), since 18S rRNA gene sequences currently represent the vast majority of available data (Rindi et al. 2011). Amplification conditions included an initial denaturation step for 5 min at 95 °C, followed by 30 cycles of 1 min at 93 °C, 2 min at 50 °C and 3 min at 72 °C. A final elongation step for 5 min at 72 °C completed PCR amplification. The reaction mix contained 2.5 μL 10x Buffer and KCl (Tris-HCl 100 mM, pH 8.8; KCl 500 mM), 2.5 μL dNTP Mix [2 mM], 2.5 μL MgCl2 [25 mM] (all Thermo Scientific, USA), 1.5 μL BSA [10 g L-1] (Carl Roth, Germany), 1 μL of each primer [10 pmol μL-1] (Eurofins Genomics, Germany), 0.2 μL Taq DNA-Polymerase [1 U μL-1] (Thermo Scientific, USA), 700 ng of gDNA and PCR-grade water (Invitrogen, USA) to achieve a final volume of 25 μL per reaction. PCR products were checked and fractioned in a 1.5% [w/v] agarose gel. Bands were excised and purified with the Nucleospin Gel and PCR Clean-up Kit (Macherey Nagel, Germany) according to the manufacturer´s instructions. The quantity and purity of the PCR products were evaluated via UV-vis spectrophotometry with NanoDrop 2000cTM (PeqLab, Germany) and sent to Eurofins Genomics (Germany) for sequencing. The sequences were analysed by a similarity search using the BLAST software. The obtained sequences were submitted to GenBank (Accession number: SUB11048601).

Generation of liquid cultures for the implementation of the irradiation experiments was achieved by a 4-stage scale up of the microalgae strains. The respective MA were cultured on 3N-BBM agar plates which were continuously renewed. Algal cells grown on 3N-BBM agar were first cultured in 50 mL of 3N-BBM at 125 rpm (Orbital shaker 3017, GFL, Germany), thereafter in an increased volume of 200 mL. From these precultures, cultivation of each microalga was conducted in 1 L laboratory flasks (n = 3), containing 950 mL 3N-BBM. One port of a GL 45 screw cap with silicon tubing allowed gas exchange, a second port was connected to a ProSilent a 300-air pump (air flow rate =300 L h−1, JBL GmbH & Co. KG, Germany) to facilitate both, active fumigation and proper reactor mixing as illustrated in Fig. 1a. Interposed sterile Midisart 2000 PTFE venting filters (0.20 μm; Sartorius, Germany) ensured sterile conditions during gas exchange. The flasks were incubated at room temperature (23 ± 2 °C) under TL5 HO 80W 840 (MASTER) florescent lamps (coldwhite; Philips, Netherlands) and a light period of 24 hours. UV radiation stress experiments started as soon as an OD750 ≥ 1, frequently measured using a Jenway 7315 Spectrophotometer (Jenway, UK), was detected in all bioreactors.

Experimental setup for cultivation and UV irradiation. (a) Flask- based bioreactor with tubing and venting filters for gas exchange are connected to an air pump to achieve an air lift for active fumigation and vertical mixing. Additionally, a magnetic stirrer was used to induce radial mixing. (b) Arrangement of the UV-A irradiation unit: A LED panel and two ventilation units are mounted on aluminium profiles. A laboratory power supply was used as a power supply for the LED panels. (c) Schematics of the arrangement of the UV units during irradiation. (d) UV exposure experiments were performed in triplicates. Each bioreactor (A, B and C) was irradiated with an individual UV-unit and placed on a magnetic stirrer to enhance mixing. Lateral ventilation was applied to reduce thermal effects by the UV-irradiation units. The insert in (d) shows the irradiation setup in more detail. The photo-bioreactors were irradiated from one side by the UV-units. Therefore, the remaining UV-irradiance is decreasing with larger distance from the LED panels and is the lowest at the backside of the photo-bioreactor. Blinds were set up to avoid UV-cross effects inbetween photo-bioreactors

Irradiation setup

Three UV-irradiation units were designed and manufactured in cooperation with the Department of Mechatronics (MCI, Innsbruck, Austria) and their schematics are shown in Fig. 1b. Each unit consisted of one LED panel, with 18 LEDs placed on an aluminium-core printed circuit board (for details please refer to Supplementary Information Fig. S1). The light-emitting diodes were arranged in a 6 x 3 array with equidistant spacing of 20 mm in horizontal direction and equal spacing of 16 mm in vertical direction. Nine LEDs emitted UV-A light at a nominal wavelength of 365 nm (AAP-CUN6AF1B; Seoul Viosys, South Korea) and a nominal wavelength of 375 nm (AAP-CUN7AF1B, Seoul Viosys, South Korea), respectively. A constant-current power supply, which was designed in-house at the Department of Mechatronics, was mounted on the back side of the LED panels and was used to ensure a steady and reproducible irradiance. For the irradiation experiments presented in this work, the current was set to a constant value of 500 mA. As a general electrical supply, a LPS 1305 power supply (Conrad Electronic AG, Switzerland) was used. The voltage setting was 20 V and the resulting total current was 1 A, as both LED wavelengths were controlled by an individual channel of the constant-current power supply and the operating current was set to 500 mA. Two lateral F12 ventilation units (ARCTIC GmbH, Switzerland) were attached to remove heat generated by the LEDs. LED panels and ventilators were mounted on a modular aluminium frame to allow a reproducible positioning of the UV-irradiation units relative to the photo-bioreactors.

UV irradiation experiment

UV-irradiation units of the presented configuration were set up. The experiments were performed at a high optical density of OD750 ≥ 1 in triplicates. The photo-bioreactors (n = 3), consisting of 1 L laboratory flasks equipped with air transfer fitting, were positioned centrally in the UV irradiation system on magnetic stirrers (IKA, Germany, magnetic stirring bars with a length of l = 3 cm), as shown in Fig. 1, to ensure sufficient mixing along with an airlift resulting from the air exchange. All experiments were performed in a temperature-controlled environment. To prevent a temperature increase of the microalgae culture caused by the irradiation system, additional fans were installed. The fans ensured a steady air exchange with the temperature-controlled environment. The setup for the UV irradiation experiment including cooling fans is shown in Fig. 1c and d. The irradiation regime was set to 72 h.

Sampling (200 mL each) was conducted prior to starting the experiment (marked in the results as time point: 0 h), followed by 24 h intervals. Sample volumes were increased by 50 mL each time, to yield approximately equal amounts of microalgae biomass. The sample quantities were replaced with 3N-BBM, respectively. The irradiation experiment was stopped after 72 h and the algae were exposed to their initial conditions, for another 24 h, before the experiment was completed. This additional 24 h with standard cultivation conditions was included in the experimental design to investigate potential regeneration effects and is marked in the results as time point: 96 h.

Light measurements

To reveal the performance of the applied UV-units, irradiance was measured in a vertical raster with a distance of 1 cm between each measurement point, in duplicates, on the outside surface of the photo-bioreactor, using a PM100D Console and a S120VC photodiode power sensor with a measurement uncertainty of ± 5% (280 – 439 nm) (Thorlabs, USA). The applied vertical raster on the photo-bioreactor is illustrated in Fig. 2a. To get a better insight in the actual spectral power distribution, spectral data of the UV-A LEDs were measured using the spectrometer MAYA 2000 Pro equipped with diffraction grating #HC-1 and entrance slit of 5 μm (Ocean Insights, USA) resulting in a spectral resolution of 0.66 nm full width at half of the intensity maximum (FWHM). The spectrometer was used along with a QP600-1-SR-BX fibre optics with a core diameter of 600 μm (Ocean Insights, USA) and a cosine corrector CC-3-UV-S (Ocean Insights, USA). For estimating the peak wavelength λpeak, where the maximum power is emitted, and the FWHM, nonlinear regression was performed by fitting a sum of Gaussian Functions to the measured spectral data (Reifegerste and Lienig 2008; Supronowicz and Fryc 2019). The nonlinear regression was performed using Matlab ONLINE 2021a (The Mathworks 2021).

Additional setup to measure UV irradiance and to determine optical conditions. (a) Irradiation was measured along a vertical raster with measurement points each spaced 1 cm apart. The vertical position 0 corresponds to the bottom of the bioreactor. The sensor was placed outside the bioreactor direct on the surface. (b) Setup to measure the dependence of the transmittance on the optical path length. The filling level of the vessel corresponds to the radial distance of the microalgal cells during UV exposure from the inner surface of the bioreactor. Thereby a filling level of 0 cm correlates to cells very close to the glass surface of the reactor, a filling level of 4 cm equals a radial cell position in the centre and a level of 8 cm is equivalent to the backside of the bioreactor vessel

Furthermore, the intensity was measured for various optical path lengths to ensure a continuous irradiation of all cells during UV exposure. As a direct determination of the transmittance in the bioreactor was impossible, a different vessel was used, and the irradiance was measured for different filling levels. Each filling level corresponds to a radial distance from the inner surface of the bioreactor vessel. Absorption loss by the glass was determined by measuring the irradiance before and after the glass wall without any biomass and was taken into account when calculating the transmittance. The additional setup for transmittance measurement is shown in Fig. 2b. Intensity was measured using a PM100D Console and a S120VC photodiode power sensor with a measurement uncertainty of ± 5% (280 – 439 nm) (Thorlabs, USA) and the transmittance T = I/I0 was calculated by the ratio intensity at a certain filling level I and the intensity without biomass I0. All light measurements were performed with biomass samples at an optical density of OD750 ≈ 1.

Sample extraction

To extract metabolites, 25 mg dried microalgae biomass, 1.25 g glass beads (diameter 0.25 mm to 0.5 mm) and 4 mL solvent ̶ equal volumes of dichloromethane and ethanol (v/v) were vortexed (Vortex Mixer with adapter for 9 tubes, StarLab) for three minutes to disrupt cell integrity and subsequently centrifuged at 4600 rpm for 15 min at 20 °C (Rotanta 460 R Hettrich, Germany). For preparation of dried biomass, the same method was used as described in “High-performance liquid chromatography standard curve determination” section. Biomass pellets were extracted two more times, using 3 mL solvent, in the same way. To remove solvents, the collected supernatants were placed under the fume cupboard overnight, and in a concentrator 5301 (Eppendorf, Germany) at 60 °C for 1.5 h to facilitate solvent removal. Extracted metabolites were stored at -20 °C. The entire extraction, and storage, were carried out under conditions preventing light exposure.

High-performance liquid chromatography standard curve determination

High-performance liquid chromatography (HPLC) was performed in a Dionex Ultimate 3000 HPLC system made up of a HPG-3400A quaternary pump with a SRD-3400 solvent degasing unit, a TCC-3100 column thermostat compartment, a WPS-3000 temperature controlled autosampler and a VWD-3100 variable wavelength detector (Thermo Fisher Scientific, USA).

Metabolite standards (Sigma Aldrich, USA) were injected in quantities of 100 μg mL−1 for astaxanthin and β-carotene and 75 μg mL−1 for canthaxanthin. The mean retention times of astaxanthin (480 nm), canthaxanthin (480 nm), and β-carotene (450 nm) were detected after 6.07, 8.63 and 16.8 min, respectively (Supplementary Information Fig. S2). Data obtained from standard curve determination are presented in Table 1. The limits of detection (LOD) and quantification (LOQ) were determined according to literature (European Medicines Agency 1995; Kromidas 2011), to validate analytical procedures.

Metabolite analysis

Astaxanthin, β-carotene and canthaxanthin were separated in a reverse phase LiChrospher 100 C18 column (Merck, USA). Two eluents, eluent A - acetonitrile (Chromanorm; VWR, USA) and methanol (Chromanorm; VWR) in a ratio of 74:6 (v/v) and eluent B - methanol (Chromanorm; VWR) to n-hexane (LiChrosolvin; Merck, USA) in a ratio of 5:1 (v/v), were used. The elution program was started with eluent A, for 4 min, followed by a linear gradient with eluent B for 8 min. Thereafter, initial conditions were repeated for another 3 min. Extracted samples were analysed with setting of 30 μL injection volume at a flow rate of 1 mL min−1 and at a temperature of 40 °C. Monitoring was performed at wavelengths of 450 nm for β-carotene and at 480 nm for astaxanthin and canthaxanthin, respectively.

Statistical analyses

Data analysis was performed using SigmaPlot v14.5 (Systat Software Inc., USA). For statistical analysis, a paired t-test was performed using Graphpad Prism 9 (GraphPad Software, USA). Results are given as mean (n = 3) and error bars correspond to the standard deviation unless stated otherwise.

Results

Identification of microalgae

BLAST searches against the nr database at NCBI revealed that the 18S rDNA sequences of the algae were most similar to sequences of the classes Trebouxiophyceae and Chlorophyceae. The results for each alga, obtained from independent PCR runs using the two previously mentioned primer pairs Pras A and Pras B, were found to be consistent. Two sequences (T3 and IB256) could be assigned to the genus Coccomyxa (AC277064.1 and KM020151.1 with >99% sequence similarity), which appeared elongated cylindrical to ellipsoidal in shape and were mostly characterized by a single parietal chloroplast without any flagellated stages, though two chloroplasts were also rarely observed (Fig. 3a and b). Two sequences (V142 and V46) were related to Chromochloris spp. (MW075314.1 and KF673375.1 with >97% and >99% sequence similarity, respectively) that showed a spherical and unicellular shape without flagellum (Fig. 3c and d). The cell size may vary depending on the growth conditions and stages and is usually between 2 µm to 15 μm in diameter (Zhang et al. 2021), which is consistent with our observations. While cells appear green under favourable growth conditions, they turn orange under stress due to the induction of secondary carotenoids like astaxanthin as visible in Fig. 3d. One sequence related to Diplosphaera sp. (V224; previously uploaded in GenBank as strain MCI_28, MK425685.1, >99% similarity) that occurred in spherical clusters with a cup-shaped, parietal chloroplast and varied in size between 3–7 μm in diameter (Fig. 3e). Cells were either singular or formed dyads (two connected cells). Diplosphaera spp. are phylogenetically nested within the Prasiola clade, class Trebouxiophyceae.

Microscopic identification of the algal strains at 1000x magnification after 7 days of cultivation. The microalgal strains T3 (a) and IB256 (b) could be assigned to Coccomyxa spp., the strains V142 (c) and V46 (d) were related to Chromochloris spp. and strain V224 (e) could be assigned to Diplosphaera sp. Typical orange-colored cells due to carotenoid accumulation (arrow), indicating the ability of successful biosynthesis.

Irradiation performance

The measured vertical irradiance distribution is shown in Fig. 4a for the mean values of all three photo-bioreactors A, B and C. The distribution has its maximum value of 51 mW cm-2 at a vertical position around 7 cm, which is half the height of the photo-bioreactor vessel and is decreasing symmetrically to the lower (position 2 cm) and upper border (position 12 cm) of the reactor. The lowest values were 22 mW cm-2 at the position 2 cm and 26 mW cm-2 at the position 12 cm. An overall irradiance of 36 ± 9 mW cm−2 was determined (dotted line in Fig. 4a). For the three individual photo-bioreactors A, B, and C, the mean irradiance of all measured positions revealed averages of 36 ± 17 mW cm−2, 36 ± 15 mW cm−2 and 38 ± 16 mW cm−2, respectively.

Measured vertical and radial irradiance distribution. (a) The mean irradiance in three reactors exposed to UV light from LED panels, measured in a vertical raster with a distance of 1 cm between each measurement point. The vertical position 0 corresponds to the bottom of the bioreactor. The mean irradiance value of the respective measuring points in all three reactors is shown by the dotted line. (b) Transmittance dependent on optical pathway. The irradiance is decreasing exponential with increasing optical pathlength, which is consistent with Beer-Lambert-Law (line). Small deviations occur for pathlength larger than 4 cm.

The dependence of the transmittance on the optical pathway in radial direction of the photo-bioreactor is shown in Fig. 4b. The reduction of the transmittance towards longer optical pathways is consistent with Beer-Lambert law and shows small deviations for pathlengths larger than 4 cm. The irradiance at the center of the bioreactor (optical pathlength of around 4 cm) is approximately 0.5% of the incident irradiance. At the back half of the photo-bioreactor, corresponding to the side of the vessel that is not directly irradiated, the remaining irradiance is less than 0.1% of the incident irradiance and close to the detection limit of the used radiometer.

The applied irradiance in vertical direction is not uniform as shown in Fig. 4a. This deviation is due to an equidistant arrangement of the single LED chips on the circuit board. Because of the overlapping spatial irradiation distribution of the single LED points, the irradiance has its maximum at the center of the photo-bioreactor (position 7 cm) and is decreasing towards the outer vertical positions (2 cm and 12 cm, respectively). This could be reduced by a non-equidistant arrangement of the LED chips on the PCB board. To find the right positioning, non-linear optimization can be used which results in larger LED distances at the center and smaller LED distances for the outer LEDs. A detailed method to optimize uniformity is given in a previous work (Fiala et al. 2021). Looking at the transmittance with respect to the optical pathway (Fig. 4b), the reduction is consistent with Beer-Lambert law. As the optical density of the exposed biomass was around one, light scattering effects also occur and get more prominent for larger optical pathways. This is also consistent with our measurements, as the transmittance deviates noticeable from a linear behavior for pathlengths larger than 4 cm in the logarithmic scale. Although the irradiation is decreasing strongly with increasing pathlengths, UV-radiation remains at the centre of the photo-bioreactor at a radial position of around 4 cm. Due to sufficient mixing using an airlift and a magnetic stirrer, all cells were evenly exposed to UV light during the irradiation experiment.

The spectral power distribution of the LED panels is shown in Fig. 5. A nonlinear regression resulted in a peak wavelength of λpeak = 369 nm and a full width at half of the intensity maximum of FWHM = 11 nm for LEDs with a nominal wavelength of 365 nm (from manufacturer´s datasheet). For the LEDs with a nominal wavelength of 375 nm, a peak wavelength of λpeak = 376 nm and a full width at half of the intensity maximum of FWHM = 12 nm was determined. To fully characterize the spectral power distribution, the full width at ten percent of the intensity maximum (FW 0.1 ∙ Imax) is a useful quantity. This value describes the spectral width at which 90% of the total optical power is emitted. The full width at ten percent of the intensity maximum is FW 0.1 ∙ Imax = 25 nm and FW 0.1 ∙ Imax = 29 nm for the LED with a nominal wavelength of 365 nm and 375 nm, respectively. A detailed display of the non-linear regression can be found in Supplementary Information Fig. S3. Our measurement of the spectral power distribution resulted in a peak wavelength and FWHM of λpeak = 369 nm ± 11 nm and λpeak = 376 nm ± 12 nm for both UV-A LED types and are within the specification limits λspec = 365 nm ± 9 nm (FWHM) and λspec = 375 nm ± 9 nm (FWHM) stated by the manufacturer. The small deviation can be explained by a different operating point regarding current and temperature. From the datasheet follows, that different operating temperatures and operating currents lead to a spectral shift.

Metabolite concentrations

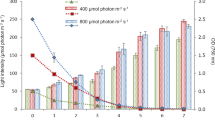

Metabolites, extracted in the UV radiation experiment were quantified based on the respective peak areas and the determined standard curves (Supplementary Information Table 1). For V142 (Fig. 6a), UV-A treatment was found to boost biosynthesis of canthaxanthin (p<0.01) and β-carotene (p<0.05) significantly, which led to an increase of 724% and 229%, between 0 and 72 hours. Thereafter, concentrations declined by 37% and 16%, respectively. Simultaneously, astaxanthin stagnated (25 ± 4 μg mL-1) under UV-A treatment but was found to be slightly increased (29%), during the regeneration phase after 96 h (Fig. 6a).

Identified concentrations of astaxanthin, canthaxanthin and β-carotene (in μg mL-1) via high-performance liquid chromatography as well as optical densities (OD750) during 72 h of UV-A irradiation (UV) and 24 h of regeneration (R) using the terrestrial microalgae V142 (a), IB256 (b), V46 (c), T3 (d) and V224 (e). Results are given as mean ±SD (n=3).

In treatments using strain IB256 (Fig. 6b), astaxanthin concentrations were below the detection limit of 1.22 μg mL-1. Concentrations of canthaxanthin (p<0.05) increased significantly between 0 and 72 hours, and concentrations of β-carotene showed considerably higher concentrations; however, the yield improvement was found to be much higher (202%) for canthaxanthin when compared with β-carotene (20%). After being exposed to their initial conditions without UV-A radiation (regeneration phase), the concentrations decreased, by 50%, for canthaxanthin but slightly increased (10%) for β-carotene (Fig. 6b).

Low β-carotene and canthaxanthin concentrations were detected in treatments of V46 (Fig. 6c), while astaxanthin was found to be below the detection limit. Canthaxanthin concentrations increased during UV-A radiation, revealing significantly increased yields of 384% (p<0.05) within 72 h. In contrast, concentrations of β-carotene were found to be only slightly increased (63%). Canthaxanthin as well as β-carotene concentration declined during the regeneration phase by 57% and 61%, respectively.

Interestingly, in T3, concentrations of both, canthaxanthin and β-carotene, were found to be highest after 48 h, revealing a significant yield improvement of 144% (p<0.05) for canthaxanthin and a 48% enhancement of β-carotene (Fig. 6d). Prolonged UV-A radiation led to decreasing concentrations of canthaxanthin (24%) and β-carotene (12%) between 48 and 96 h. Astaxanthin could be detected in steady quantities of 11.2 ± 0.2 μg mL-1 throughout the experiment.

Astaxanthin, canthaxanthin and β-carotene concentrations of V224 showed low but steady quantities, within 96 h, revealing concentrations of 10.6 ± 0.004 μg mL-1, 4.5 ± 0.2 μg mL-1 and 1.0 ± 0.1 μg mL-1, respectively (Fig. 6e).

V142, IB256, V46, T3 and V224 revealed an OD750 of 1.3± 0.1, 3.1 ±0.2, 1.2± 0.02, 1.9 ± 0.1 and 2.5 ± 0.2 at the start of the experiment. Between 0 and 72 h, optical densities decreased by 67%, 62%, 54%, 62%, and 64%, respectively, in all treatments and, increased, after that, by 29%, 15%, 4%, and 135%, in V142, IB256, V46 and T3, respectively. In V224 treatments, a declining OD750 (by 24%) was measured throughout the entire investigation period extending over 96 h.

The impact of UV light stress on the canthaxanthin and β-carotene concentrations on all five investigated strains is summarized in Fig. 7. UV-A irradiation increased the canthaxanthin production in the strains V142, IB256, V46 and T3 significantly (Fig. 7a). There was also a significant enhancement in the β-carotene production in V142 due to UV-A light stress, and the concentration in IB256, V46 and T3 was increased (Fig. 7b)

Discussion

Besides the strong adaptability to changing environmental conditions, advantages of using microalgae as natural sources for the production of carotenoids include (i) the easy, cheap and environmentally friendly synthesis, (ii) their multiple metabolic modes and (iii) their rapid growth compared with plants, particularly regarding members of Chlorophyceae (Liu et al. 2021). During the past years, various studies have reported that both environmental and culture-stimulating factors can significantly increase carotenoid accumulation. Among the frequently investigated parameters were light and temperature regulation and the addition of metal ions and salts (Liu et al. 2021). In this context, blue and/or red-light conditions showed a 67%-and 31% to 58% increase in astaxanthin and β-carotene concentrations using Haematococcus pluvialis and Dunaliella salina, respectively (Pereira and Otero 2020; Xi et al. 2020). An increase in the level of ROS and an upregulation of biosynthesis-related genes was reported to stimulate astaxanthin accumulation under high light conditions of a photon flux density of 150 μmol photons m−2 s−1 by Ding et al. (2019). UV-A illumination (350 nm) increased chlorophyll-α and β-carotene content of Ettlia sp. up to 248% and 621% in 500 mL photo-bioreactors, respectively, after 48 h (Lee et al. 2018). In a study of Mogedas et al. (2009) β-carotene contents were found 100% increased for Dunaliella bardawil (=D. salina), when cultivated in 3.2 L stirred bioreactors under UV-A for 24 h. Huang et al. (2018), who investigated the effect of UV-A (365 nm) on bioactive microalgal metabolites, revealed significant boosts in β-carotene and canthaxanthin production after 72 h: The first two metabolites were found increased by 267% and 200%, whereas astaxanthin concentration did not change for Nitzschia closterium. In our study, a similar behaviour was found in strain V142. While β-carotene and canthaxanthin concentration was increased during UV treatment, the astaxanthin concentration did not change during UV stress. However, astaxanthin concentration increased thereafter under post-UV conditions, revealing gains of 60% compared to the initial astaxanthin concentration. These results indicate a yet unexplored potential of a downstream regeneration phase subsequent to UV-stress to boost carotenogenesis. For Isochrysis zhangjiangensis β- carotene was found decreased by 33%. Canthaxanthin and astaxanthin increased by 225% and 163%, respectively. In the present investigation, UV-A treatment significantly boosted carotenoid synthesis within 72 h in three of the five terrestrial microalgae, revealing gains of up to 724% and 229% for canthaxanthin and β-carotene, respectively, within 72 h. In general, carotenoid accumulation started rapidly to increase within 24 h and continued to increase until the end of UV-A treatment (72 h), while declined again during the regeneration phase (Fig. 6a-e). Consistent with previous studies, increasing carotenoid concentrations were accompanied by decreasing optical densities (Fig. 6a-e) most probably due to suboptimal growth conditions caused by UV-A stress (Döhler et al. 1997; Jahnke 1999). However, the growth of UV-A treated strains started to increase again during the regeneration phase (Fig. 6a-e), indicating effective defence and adaptation mechanisms to UV exposure. These results pointed to the fact that the production of photoprotective pigments play a major role in oxidative stress resistance, since carotenoids including β-carotene and astaxanthin are known to be efficient physical and chemical quenchers of singlet oxygen as well as scavengers of other ROS (Reis-Mansur et al. 2019). Whereas Chlorophyceae-related strains (e.g., Chromochloris spp.) are frequently exploited in literature for their potential to accumulate carotenoids under abiotic stress conditions, data on Coccomyxa spp. are rare. Interestingly, strain IB256 (which is related to the genus Coccomyxa) exhibited an outstanding potential for carotenogenesis under UV-A stress and reached the highest canthaxanthin and β-carotene concentrations during 72 h of investigation (Fig. 7a and b; Supplementary Information Table 1). Although the yield improvement was observed to be the highest using strain V142 (related to the genus Chromochloris), also Coccomyxa-related strain T3 accumulated considerable amounts of canthaxanthin and β-carotene, however, they were found to peak after 48 h in contrast to the other four algae revealing maximum yields after 72 h (Supplementary Information Table 1). Overall, the results of the present investigation confirm the hypothesis that terrestrial microalgae possess a promising potential for carotenogenesis induced by UV-A light stress and provide a promising basis for further biotechnological exploitation regarding the enhanced production of valuable carotenoids from terrestrial microalgae by UV-A treatment. The investigated strains could be assigned to the genera Chromochloris, Coccomyxa and Diplosphaera, which are known to exist in harsh environments and therefore developed various survival strategies including the synthesis of secondary metabolites. By exposing them to UV-A light stress under well-defined irradiation conditions, a significant increase in the concentrations of the carotenoids β-carotene and canthaxanthin could be determined. Taking into account that only few of thousands microalgae species have as yet been scientifically described and are kept in culture, with an even smaller fraction being used for commercial application (Novoveská et al. 2019), investigating the eco-physiological and biotechnological potential of terrestrial microalgae might offer substantial opportunities to promote natural carotenoid production. In this context, using LED-based UV-A light to enhance the production of industrial relevant metabolites harbours significant future potential, as it is easy to implement in bioreactors and LEDs are a reliable and energy efficient light source. Established methods so far, such as the addition of metal ions or salts as nutrient stress factors to boost carotenogenesis require adaption of the respective cultivation media. However, UV-A exposure can be easily applied and withdrawn while not severely interfering in the cultivation process.

Data availability

Data will be made available on reasonable request. The datasets presented in this study can be found in online repositories. The names of the repository/repositories and accession number(s) can be found in the article.

References

Abe K, Hattori H, Hirano M (2007) Accumulation and antioxidant activity of secondary carotenoids in the aerial microalga Coelastrella striolata var. multistriata. Food Chem 100:656–661

Aburai N, Ohkubo S, Miyashita H, Abe K (2013) Composition of carotenoids and identification of aerial microalgae isolated from the surface of rocks in mountainous districts of Japan. Algal Res 2:237–243

Bischoff HW, Bold HC (1963) Phycological Studies IV-Some Soil Algae from Enchanted Rock and Related Algal Species. Phycological Studies, IV. University of Texas, Austin Texas, Texas

Borowitzka MA (2013) High-value products from microalgae—their development and commercialisation. J Appl Phycol 25:743–756

Cardozo KHM, Guaratini T, Barros MP, Falcão VR, Tonon AP, Lopes NP, Campos S, Torres MA, Souza AO, Colepicolo P, Pinto E (2007) Metabolites from algae with economical impact. Comp Biochem Physiol C 146:60–78

Christaki E, Bonos E, Giannenas I, Florou-Paneri P (2013) Functional properties of carotenoids originating from algae. J Sci Food Agric 93:5–11

Ding W, Peng J, Zhao Y, Zhao P, Xu J-W, Li T, Yu X (2019) A strategy for boosting astaxanthin accumulation in green microalga Haematococcus pluvialis by using combined diethyl aminoethyl hexanoate and high light. J Appl Phycol 31:171–181

Döhler G, Drebes G, Lohmann M (1997) Effect of UV-A and UV-B radiation on pigments, free amino acids and adenylate content of Dunaliella tertiolecta Butcher (Chlorophyta). J Photochem Photobiol B 40:126–131

European Medicines Agency (1995) ICH Topic Q2 (R1) Validation of Analytical Procedures: Text and Methodology p15. https://www.ema.europa.eu/en/ich-q2r2-validation-analytical-procedures

Fiala J, Schöbel H, Vrabl P, Dietrich D, Hammerle F, Artmann DJ, Stärz R, Peintner U, Siewert B (2021) A new high-throughput-screening-assay for photoantimicrobials based on EUCAST revealed unknown photoantimicrobials in Cortinariaceae. Front Microbiol 12:703544

Fais G, Malavasi V, Scano P, Soru S, Caboni P, Cao G (2021) Metabolomics and lipid profile analysis of Coccomyxa melkonianii SCCA 048. Extremophiles 25:357–368

Gärtner G (1996) ASIB–The culture collection of algae at the Botanical Institute of the University at Innsbruck (Austria), catalogue of strains 1996. Berichte des Naturwissenschaftlich-Medizinischen Vereins in Innsbruck 83:45–69

Hodkinson T, Jones M, Waldren S, and Parnell J (Eds.) (2011) Climate change, ecology and systematics (systematics association special volume series). Cambridge University Press, Cambridge

Hoffmann L (1989) Algae of terrestrial habitats. Bot Rev 55:77–105

Huang JJ, Lin S, Xu W, Cheung PCK (2018) Enhancement of the production of bioactive microalgal metabolites by ultraviolet radiation (UVA 365 nm). J Agric Food Chem 66:10215–10224

Jahnke LS (1999) Massive carotenoid accumulation in Dunaliella bardawil induced by ultraviolet-A radiation. J Photochem Photobiol B 48:68–74

Kalinowska R, Pawlik-Skowrońska B (2010) Response of two terrestrial green microalgae (Chlorophyta, Trebouxiophyceae) isolated from Cu-rich and unpolluted soils to copper stress. Environ Pollut 158:2527–2792

Karsten U (2008) Defense Strategies of algae and cyanobacteria against solar ultraviolet radiation. In: Amsler CD (ed) Algal Chemical Ecology. Springer, Berlin, pp 273–296

Koechler S, Bertin PN, Plewniak F, Baltenweck R, Casiot C, Heipieper HJ, Bouchez O, Arsène-Ploetze F, Hugueney P, Halter D (2016) Arsenite response in Coccomyxa sp. Carn explored by transcriptomic and non-targeted metabolomic approaches. Environ Microbiol 18:1289–300

Kromidas S (2011) Validierung in der Analytik. Wiley-VCH, Weinheim

La Rocca N, Andreoli C, Giacometti GM, Rascio N, Moro I (2009) Responses of the Antarctic microalga Koliella antarctica (Trebouxiophyceae, Chlorophyta) to cadmium contamination. Photosynthetica 47:471–479

Lakatos M, Strieth D (2017) Terrestrial Microalgae: Novel concepts for biotechnology and applications. Progr Bot 79:269–312

Lee N, Ko S-R, Ahn C-Y, Oh H-M (2018) Optimized co-production of lipids and carotenoids from Ettlia sp. by regulating stress conditions. Bioresour Technol 258:234–239

Liang Y, Beardall J, Heraud P (2006) Effect of UV radiation on growth, chlorophyll fluorescence and fatty acid composition of Phaeodactylum tricornutum and Chaetoceros muelleri (Bacillariophyceae). Phycologia 45:605–615

Liu C, Hu B, Cheng Y, Guo Y, Yao W, Qian H (2021) Carotenoids from fungi and microalgae: A review on their recent production, extraction, and developments. Bioresour Technol 337:125398

McManus HA, Lewis LA (2011) Molecular phylogenetic relationships in the freshwater family Hydrodictyaceae (Sphaeropleales, Chlorophyceae), with an emphasis on Pediastrum duplex. J Phycol 47:152–163

Mc Gee D, Archer L, Paskuliakova A, Mc Coy GR, Fleming GTA, Gillespie E, Touzet N (2018) Rapid chemotaxonomic profiling for the identification of high-value carotenoids in microalgae. J Appl Phycol 30:385–399

Medwed C, Holzinger A, Hofer S, Hartmann A, Michalik D, Glaser K, Karsten U (2021) Ecophysiological, morphological, and biochemical traits of free-living Diplosphaera chodatii (Trebouxiophyceae) reveal adaptation to harsh environmental conditions. Protoplasma 258:1187–1199

Mogedas B, Casal C, Forján E, Vílchez C (2009) β-carotene production enhancement by UV-A radiation in Dunaliella bardawil cultivated in laboratory reactors. J Biosci Bioeng 108:47–51

Mussagy CU, Winterburn J, Santos-Ebinuma VC, Fernando J, Pereira B (2019) Production and extraction of carotenoids produced by microorganisms. Appl Microbiol Biotechnol 103:1095–1114

Novoveská L, Ross ME, Stanley MS, Pradelles R, Wasiolek V, Sassi J-F (2019) Microalgal carotenoids: A review of production, current markets, regulations, and future direction. Mar Drugs 17:640

Nwoba EG, Parlevliet DA, Laird DW, Alameh K, Moheimani NR (2019) Light management technologies for increasing algal photobioreactor efficiency. Algal Res 39:101433

Orekhova A, Barták M, Özkar A, Elster J (2019) The effect of shock freezing on physiological properties and consequent growth of Antarctic filamentous (Stigeoclonium sp.) and coccal alga (Diplosphaera chodatii) on agar plates. Czech Polar Rep 9:34–48

Pereira S, Otero A (2020) Haematococcus pluvialis bioprocess optimization: Effect of light quality, temperature and irradiance on growth, pigment content and photosynthetic response. Algal Res 51:102027

Pfaff S, Borchhardt N, Boy J, Karsten U, Gustavs L (2016) Desiccation tolerance and growth-temperature requirements of Coccomyxa (Trebouxiophyceae, Chlorophyta) strains from Antarctic biological soil crusts. Algol Stud 151–152:3–19

Rastogi RP, Madamwar D, Nakamoto H, Incharoensakdi A (2020) Resilience and self-regulation processes of microalgae under UV radiation stress. J Photochem Photobiol C 43:100322

Reifegerste F, Lienig J (2008) Modelling of the temperature and current dependence of LED spectra. J Light Vis Environ 32:288–294

Reis-Mansur MCPP, Cardoso-Rurr JS, Silva JVMA, de Souza GR, Cardoso VS, Mansoldo FRP, Pinheiro Y, Schultz J, Lopez Balottin LB, da Silva AJR, Lage C, dos Santos EP, Rosado AS, Vermelho AB (2019) Carotenoids from UV-resistant Antarctic Microbacterium sp. LEMMJ01. Sci Rep 9:9554

Rindi F, McIvor L, Sherwood AR, Friedl T, Guiry MD, Sheath RG (2007) Molecular phylogeny of the green algal order Prasiolales (Trebouxiophyceae, Chlorophyta). J Phycol 43:811–822

Rindi F, Hodkinson T, Jones M (2011) Terrestrial green algae: Systematics, biogeography and expected responses to climate change. In: Hodkinson TR, Jones MB, Waldren S, Parnell JAN (eds) Climate change, ecology and systematics. Cambridge University Press, Cambridge, pp 201–227

Sánchez-Bayo A, Morales V, Rodríguez R, Vicente G, Bautista LF (2020) Cultivation of microalgae and cyanobacteria: effect of operating conditions on growth and biomass composition. Molecules 25:2834

Sathasivam R, Ki J-S (2018) A review of the biological activities of microalgal carotenoids and their potential use in healthcare and cosmetic industries. Mar Drugs 16:26

Supronowicz R, Fryc I (2019) The LED spectral power distribution modelled by different functions - how spectral matching quality affected computed LED color parameters. Proceedings of Balkan Light Junior 2019 conference: Second Balkan Junior Conference on Lighting (Balkan Light Junior):19–21, Plovdiv, Bulgaria. IEEE, Piscataway, New Jersey, pp 1–4. https://doi.org/10.1109/BLJ.2019.8883564

The Mathworks I (2021) MATLAB ONLINE R2021a, Natick, Massachusetts, USA

Xi Y, Wang J, Chu Y, Chi Z, Xue S (2020) Effects of different light regimes on Dunaliella salina growth and β-carotene accumulation. Algal Res 52:102111

Zhang Y, Ye Y, Bai F, Liu J (2021) The oleaginous astaxanthin-producing alga Chromochloris zofingiensis: potential from production to an emerging model for studying lipid metabolism and carotenogenesis. Biotechnol Biofuels 14:119

Acknowledgments

The authors would like to thank Dr. Peter Leitner and Dr. Alexander Trockenbacher, the Department of Mechatronics (MCI) and the Department of Botany, University of Innsbruck for assistance with cultivation, for production of the UV-irradiation system and providing the algal strains. Experimental setups (Figs. 1 and 2) were created with BioRender.com.

Funding

Open access funding provided by MCI Management Center Innsbruck – Internationale Hochschule GmbH. This study was funded by the Tyrolean Science Fund (TWF, GZ UNI-0404-2335).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by L.C., M.M. and H.S. The first draft of the manuscript was written by M.M., A.W., C.G., and H.S. and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

ESM 1

(PDF 379 kb)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mutschlechner, M., Walter, A., Colleselli, L. et al. Enhancing carotenogenesis in terrestrial microalgae by UV-A light stress. J Appl Phycol 34, 1943–1955 (2022). https://doi.org/10.1007/s10811-022-02772-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-022-02772-5