Abstract

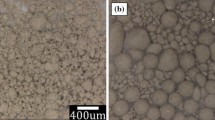

In nuclear reactors, the performance of uranium dioxide \((\hbox {UO}_{2})\) fuel is strongly dependent on the thermal conductivity, which directly affects the fuel pellet temperature, the fission gas release and the fuel rod mechanical behavior during reactor operation. The use of additives to improve \(\hbox {UO}_{2}\) fuel performance has been investigated, and beryllium oxide (BeO) appears as a suitable additive because of its high thermal conductivity and excellent chemical compatibility with \(\hbox {UO}_{2}\). In this paper, \(\hbox {UO}_{2}\)–BeO pellets were manufactured by mechanical mixing, pressing and sintering processes varying the BeO contents and compaction pressures. Pellets with BeO contents of 2 wt%, 3 wt%, 5 wt% and 7 wt% BeO were pressed at 400 MPa, 500 MPa and 600 MPa. The laser flash method was applied to determine the thermal diffusivity, and the results showed that the thermal diffusivity tends to increase with BeO content. Comparing thermal diffusivity results of \(\hbox {UO}_{2}\) with \(\hbox {UO}_{2}\)–BeO pellets, it was observed that there was an increase in thermal diffusivity of at least 18 % for the \(\hbox {UO}_{2}\)-2 wt% BeO pellet pressed at 400 MPa. The maximum relative expanded uncertainty (coverage factor k = 2) of the thermal diffusivity measurements was estimated to be 9 %.

Similar content being viewed by others

References

A.A. Kovalishina, V.N. Prosyolkova, V.D. Sidorenkoa, Y.V. Stogovb, Phys. At. Nucl. 77, 1661 (2014)

D.S. Li, H. Garmestani, J. Schwartz, J. Nucl. Mat. 392, 22 (2009)

W. Zhou, R. Liu, S.T. Revankar, Ann. Nucl. Energy 81, 240 (2015)

A.A. Solomon, S. Revankar, J.K. McCoy, Enhanced thermal conductivity oxide fuels. (Project \(\text{N}^{\circ }\). 02-1802005, Award \(\text{ N }^{\circ }\) DE-FG07-02SF22613, 2005), http://www.osti.gov/scitech/servlets/purl/862369-iDA0bI/. Accessed 07 June 2016

IAEA, Thermophysical properties database of materials for light water reactors and heavy water reactors. (TECDOC 1496, 2006), http://www.pub.iaea.org/MTCD/publications/PDF/te_1496_web.pdf. Accessed 14 June 2016

S. Ishimoto, M. Hirai, K. Ito, Y. Korei, J. Nucl. Sci. Tech. 33, 134 (1996)

K. McCoy, C. Mays, J. Nucl. Mat. 375, 157 (2008)

S.K. Kim, W.I. Ko, H.D. Kim, S.T. Revankar, W. Zhou, D. Jo, J. Nucl. Mat. 52, 813 (2010)

D. Chandramouli, S.T. Revankar, Int. J. Nucl. Energy 2014, 751070 (2014). doi:10.1155/2014/751070

G. Maier, Dichte und Porositätsmessung nach der Penetrations-Imersions Methode: Überprüfung und Möglichkeiten zur Verbesserung (Kraftwerk Union (Arbeits-Bericht), Erlangen, 1978)

W.J. Parker, R.J. Jenkins, C.P. Butler, G.L. Abbot, J. Appl. Phys. 9, 1679 (1961)

JCGM, Evaluation of measurement data—guide to the expression of uncertainty in measurement, JCGM 100:2008 (Joint Committee for Guides in Metrology, 2008)

ASTM E1461-13, Standard Test Method for Thermal Diffusivity by the Flash Method. (ASTM International, West Conshohocken, 2013). doi:10.1520/E1461

D.M. Camarano, F.L. Migliorini, E.H.C. Silva, P.A. Grossi, W.B. Ferraz, J.B. de Paula, Int. J. Themophys. 31, 1842 (2010)

LNE, in Test Report, Laboratorie National de Mëtrologie et D’Essais, Graphite Sample (2009)

NETZSCH Gerätebau GmbH Applications Laboratory, in Manufacture’s Certification, Thermophysical Properties Standard, Inconel 600 Sample (2009)

Acknowledgements

The authors thank the financial support of CNPq—Conselho Nacional de Desenvolvimento Científico e Tecnológico, SIBRATEC Rede GTD—Rede de Serviços Tecnológicos em Geração, Transmissão e Distribuição de Energia Elétrica and INCTRNi—Instituto Nacional de Ciência e Tecnologia de Reatores Nucleares Inovadores.

Author information

Authors and Affiliations

Corresponding author

Additional information

Selected Papers of the 13th International Symposium on Temperature, Humidity, Moisture and Thermal Measurements in Industry and Science.

Rights and permissions

About this article

Cite this article

Camarano, D.M., Mansur, F.A., Santos, A.M.M. et al. Effects of Beryllium and Compaction Pressure on the Thermal Diffusivity of Uranium Dioxide Fuel Pellets. Int J Thermophys 38, 137 (2017). https://doi.org/10.1007/s10765-017-2272-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-017-2272-0