Abstract

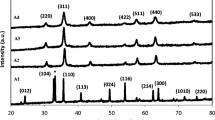

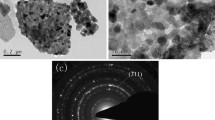

Copper ferrite nanoparticles were synthesized via the oxidation of precipitates obtained from the reaction of FeCl2, CuSO4 and N2H4 in the presence of gelatin. These copper ferrite particles were subsequently examined using powder X-ray diffraction (XRD), transmission electron microscopy (TEM), and Mössbauer spectroscopy. The average size of the copper ferrite nanoparticles was less than 5 nm, and they exhibited superparamagnetic behavior as a result of their small size. The low temperature Mössbauer spectrum exhibited three sets of sextets, two corresponding to the tetrahedral and octahedral sites of the copper spinel structure and one with small hyperfine magnetic field corresponding to the surface or defects of the nanoparticles. When the ratio of copper salt was increased, the tetrahedral site became preferable for copper, and metallic copper and copper ferrite were both present in a single nanoparticle.

Similar content being viewed by others

References

Sugimoto, M.: The past, present, and future of ferrites. J. Am. Ceram. Soc. 82, 269–280 (1999)

Goya, G.F., Rechenberg, H.R.: Superparamagnetic transition and local disorder in CuFe2O4 nanoparticles. Nanostruct. Mater. 10, 1001–1011 (1998)

Prince, E., Treuting, R.G.: The structure of tetragonal copper ferrite. Acta Cryst. 9, 1025–1028 (1956)

Subramanian, V., Gnanakumar, E.S., Jeong, D.W., Han, W.B., Gopinath, C.S., Roh, H.S.: A rationally designed CuFe2O4–mesoporous Al2O3 composite towards stable performance of high temperature water–gas shift reaction. Chem. Commun. 49, 11257–11259 (2013)

Ahmad, J., Alhadlaq, H.A., Alshamsan, A., Siddiqui, M.A., Saquib, Q., Khan, S.T., Wahab, R., Al-Khedhairy, A.A., Musarrat, J., Akhtar, M.J., Ahamed, M.: J. Appl. Toxicol. doi:10.1002/jat.3299

Singh, S., Yadav, B.C., Prakash, R., Bajaj, B., Lee, J.R.: Synthesis of nanorods and mixed shaped copper ferrite and their applications as liquefied petroleum gas sensor. Appl. Surf. Sci. 257, 10763–10770 (2011)

Lavela, P., Tirado, J.L., Womes, M., Jumas, J.C.: 57Fe Mössbauer spectroscopy study of the electrochemical reaction with lithium of MFe2O4 (M = Co and Cu) electrodes. J. Phys. Chem. C 113, 20081–20087 (2009)

Yonezawa, T., Nishida, N., Hyono, A.: One-pot preparation of antioxidized copper fine particles with a unique structure by chemical reduction at room temperature. Chem. Lett. 39, 548–549 (2010)

Jiang, J.Z., Goya, G.F., Rechenberg, H.R.: Magnetic properties of nanostructured CuFe2O4. J. Phys.: Condens. Matter 11, 4063–4078 (1999)

Goya, G.F., Rechenberg, H.R.: Structural and magnetic properties of ball milled copper ferrite. J. Appl. Phys. 84, 1101–1108 (1998)

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is part of the Topical Collection on Proceedings of the 2nd Mediterranean Conference on the Applications of the Mössbauer Effect (MECAME 2016), Cavtat, Croatia, 31 May-3 June 2016.

Rights and permissions

About this article

Cite this article

Nishida, N., Amagasa, S., Kobayashi, Y. et al. One-pot production of copper ferrite nanoparticles using a chemical method. Hyperfine Interact 237, 111 (2016). https://doi.org/10.1007/s10751-016-1321-6

Published:

DOI: https://doi.org/10.1007/s10751-016-1321-6